With reliable measurement technology and its usual high measurement precision, Fischer is making a significant contribution to the important development of antimicrobial coatings. With AGXX, the Berlin-based company Largentec offers an innovative technology that is characterized, among other things, by an excellent, long-lasting antimicrobial effect. In this context, it is of great importance for both the antimicrobial effectiveness and the cost-effectiveness of the products to adjust the layer thicknesses of the AGXX surface very precisely. X-ray fluorescence analysis instruments serve as an optimal solution to the coating thickness measurements required here.

The application of antimicrobial coatings minimizes the damage caused by microorganisms to people and the economy. Microorganisms don't just spread disease and infection. They also cause biocorrosion and fouling, which impairs the functionality of equipment and reduces the quality of the goods produced.

The patented AGXX technology is based on catalytically active coatings and layer systems of different precious metals. It is effective against more than 130 microorganisms, including the SARS-CoV-2 viruses. To ensure antimicrobial efficacy and cost-effectiveness, precise and homogeneous formation of the layer thicknesses is required. Correspondingly accurate and efficient measurements in the nanometer range are of great importance for the development of such surface systems.

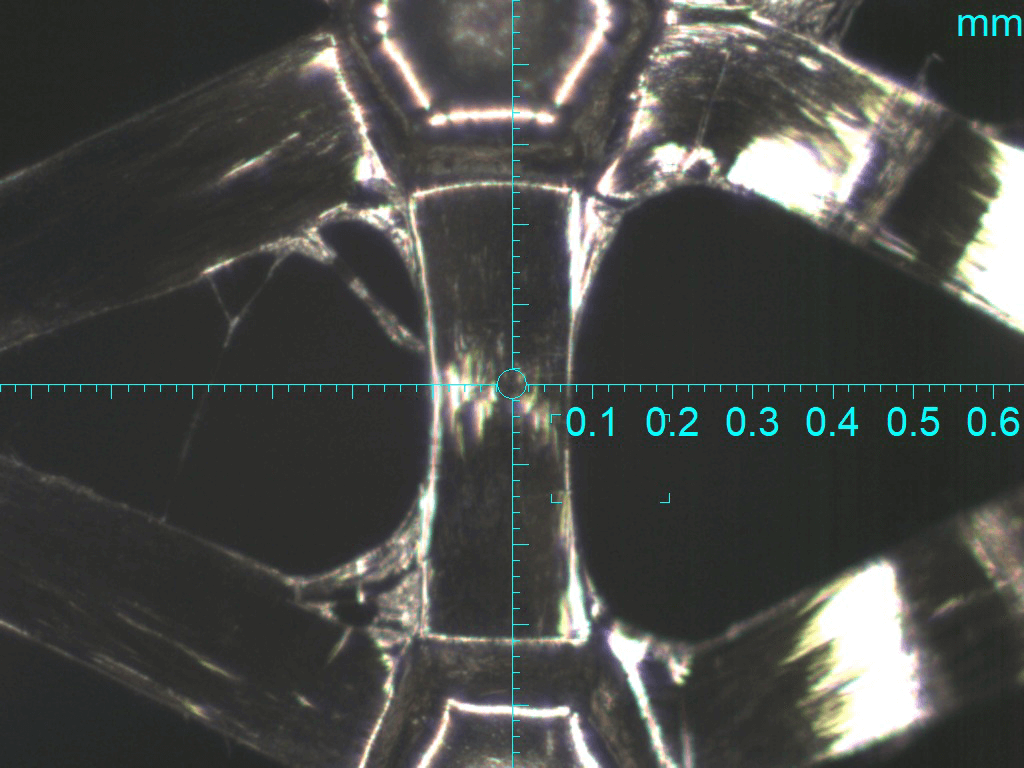

X-ray fluorescence analysis (XRF) spectrometers from Fischer provide the measurement precision and reliability required for this. In a large number of measurements in cooperation with Largentec, it was possible to measure important parameters in a short time and with the greatest accuracy. Using the Fischerscope X-ray XDV-m, one of the most powerful XRF instruments in the portfolio, PVD and CVD coated films were measured. With a measurement time per measuring point of just 15 seconds, the precision achieved was in the subnanometer range.

Such precision with such short measurement times creates the necessary conditions for optimizing the effectiveness of AGXX technology as well as its application for large-scale production of a wide variety of products such as coatings, surface alloys, films and textiles. This is because it enables faster iterations with greater accuracy in development. In other words, because of this new agility, products can be developed faster and more cost-effectively. It also gives users the ability to specifically address the technical and economic requirements of different application areas.

For more information on the measurement method, measuring devices and their various applications.