Measure ferrite content

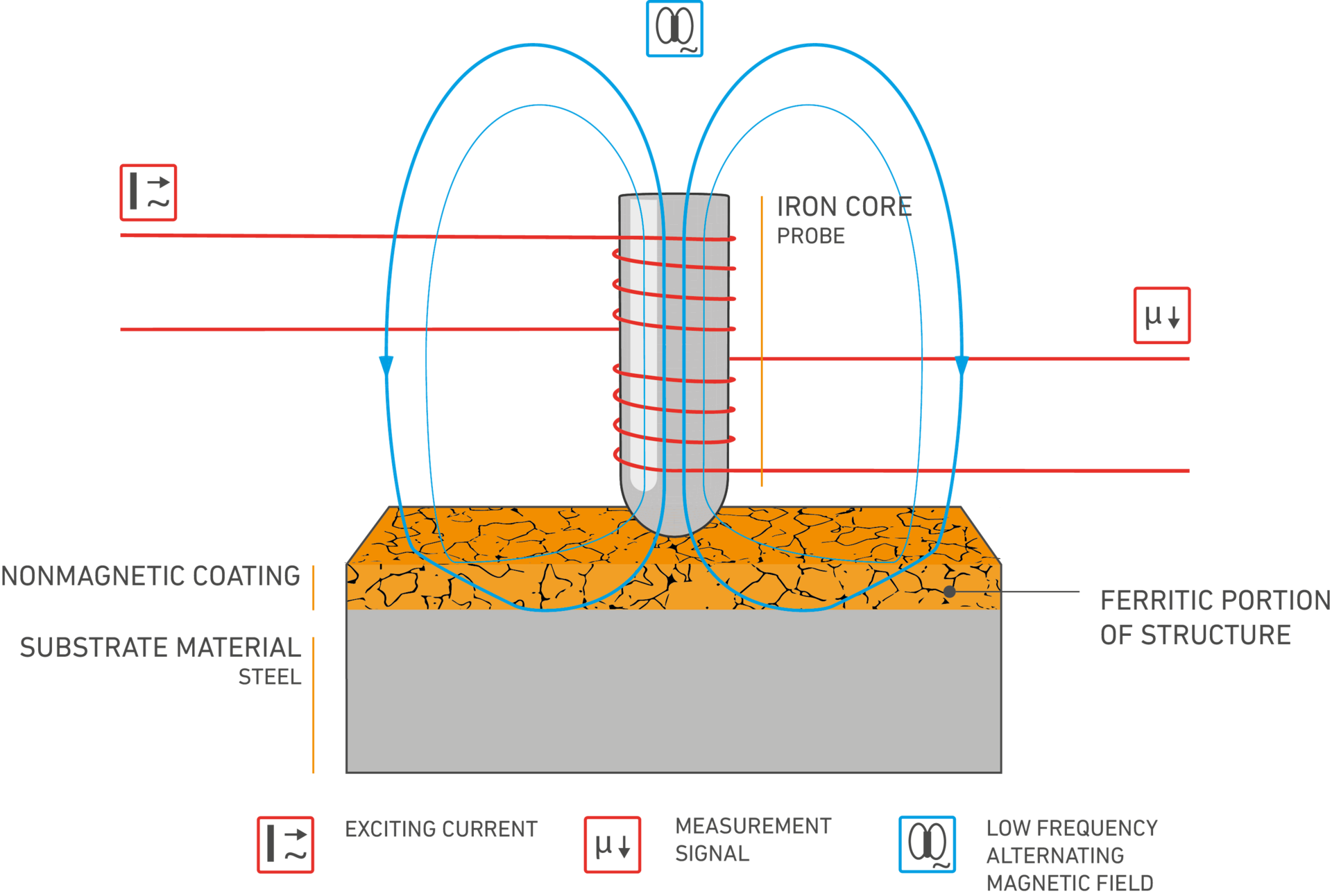

Physical principles of measuring by magnetic induction.

With the magnetic induction method, ferrite content can be determined quickly and non-destructively in accordance with the Basel standard. For example, weld seams on austenitic steel can be inspected directly onsite and, if necessary, reworked.

This is how ferrite content measurement works.

The probe for ferrite content measurement consists of an iron core around which an exciter coil is wound. A low-frequency alternating current (168 Hz) flows through this coil. This creates an alternating magnetic field around the poles of the iron core.

If the pole of the probe now approaches a steel part, the ferrite grains in the steel amplify the alternating magnetic field. A measuring coil registers this amplification as voltage. How high the voltage difference is depends on the magnetic properites of the crystal structure. Therefore, delta ferrite and deformation martensite cannot be distinguished with this method.

Where is this process used?

- Measuring all magnetic phases in a steel (δ-ferrite, α-martensite (deformation martensite))

- Determination of δ-ferrite content in: Duplex steels (40 - 60 %Fe), austenitic steels (0.5 - 12 %Fe), welds, cladding

What factors can influence the measurement?

The magnetic field of the coil spreads about 2 - 3 mm around the probe pole, both to the side and in depth. This means that an approximately cone-shaped section of the sample is observed. The method does not allow any statement about the distribution or accumulation of the delta ferrite in the material. It can happen that the measurement results of the magnetic induction method deviate strongly from the metallographic determination, because this method only records the surface distribution of the ferrite.

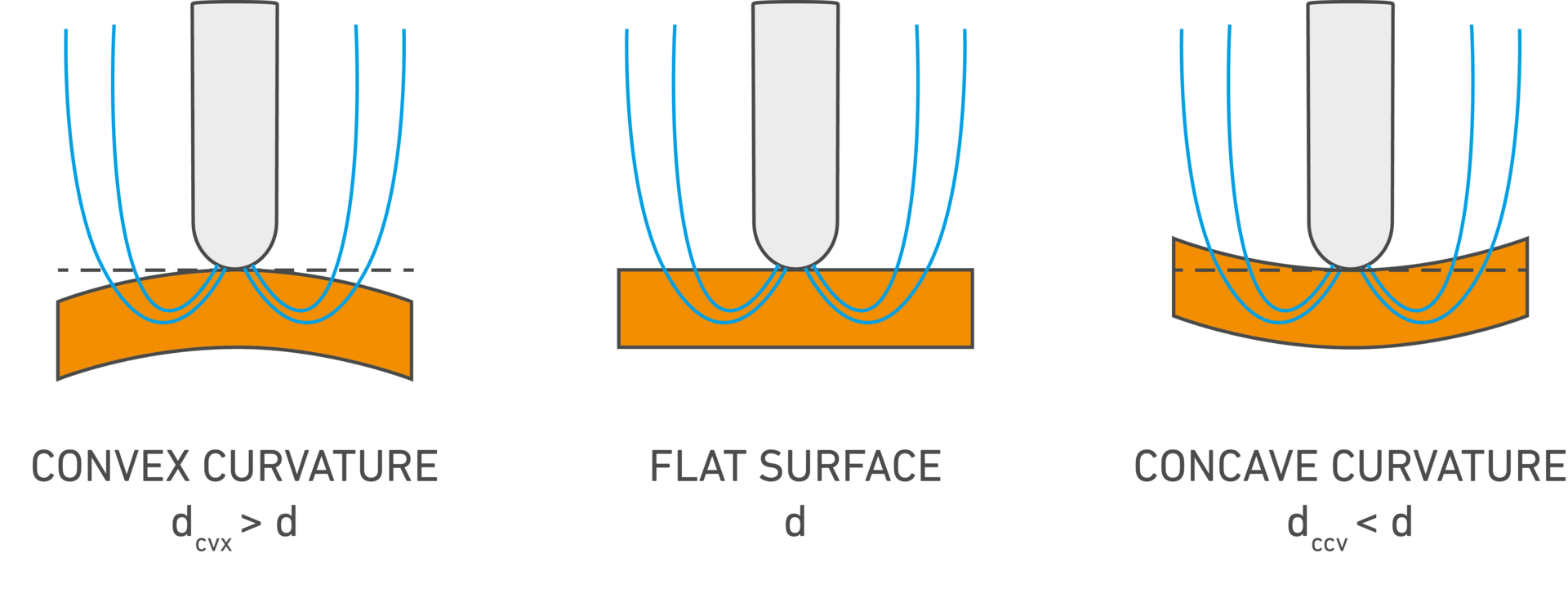

Application on curved surfaces

In practice, most measurement errors occur due to the shape of the test piece. With curved surfaces, the portion of the magnetic field that passes through the air changes. For example, if a measuring device was calibrated on a flat sheet of metal, measuring on a concave surface would produce elevated results, while measuring on a convex surface would produce low results. The errors that result can be many times the actual value of the ferrite content.

Application for small, flat parts

A similar effect can occur if the test part is small or very thin. In this case, too, the magnetic field reaches beyond the test piece and partially runs in the air, which systematically falsifies the measurement results. This influence is effective from test piece thicknesses of less than 2 mm. In principle, the thinner the test piece thickness, the greater the measurement error.

Application for rough surfaces

With rough surfaces, the result of the measurement can be falsified, depending on whether the probe pole is placed in the valley or on a peak of the roughness profile.

In general, the influence of the surface roughness is strongly dependent on the ferrite content. At ferrite contents < 10 %Fe (< approx. 10 FN), this influence is very small. However, it increases with increasing ferrite content and can best be reduced by combining a sufficient number of individual measurements into a meaningful average value.

Operation of the measuring device

Last but not least, how the measuring device is operated also plays a major role in determining the ferrite content. Always make sure the probe is held level above the coating surface and is applied to the test piece without pressure. The smaller the probe pole, the less the influence due to tilting. For better precision, a tripod can also be used to automatically lower the probe onto the test part.

Which standard is applied here?

Ferrite content measurement according to DIN EN ISO 17655