Amplitude-sensitive eddy current method

Precise measurement of non-ferrous metals with eddy current.

With the amplitude-sensitive eddy current method, you can measure the thickness of coating materials on electrically conductive but non-magnetic materials. In principle, this involves non-ferrous metals. The coating material itself must show neither electrically conductive nor magnetic properties. Typical material combinations are anodized layers on aluminum and paint, or lacquer or plastic layers on electrically conductive non-ferrous metals.

How the amplitude sensitive eddy current method works.

This measuring method uses probes with or without ferrite core. A coil is wound around these, through which a high-frequency alternating current flows. This creates a high-frequency alternating magnetic field around the coil.

If the probe pole comes close to a metal, so-called eddy currents are induced in this metal. This also generates an alternating magnetic field. Since this second magnetic field is opposite to the first one, the original magnetic field is weakened. The extent of this weakening depends on the distance between the pole and the metal base material. For coated parts, this distance corresponds to the coating thickness.

Where is this process used?

- Electrically non-conductive, non-magnetic coating materials

- e. g. paint, lacquer or plastic coatings on electrically conductive non-ferrous metals

- e. g. anodized coatings (anodizing) on aluminum

What factors can influence the measurement?

All electromagnetic measuring methods are comparative. This means that the measured signal is compared with a characteristic curve stored in the device. To ensure that the result is correct, the characteristic curve must be adapted to the current conditions. This is basically done by calibrating the measuring device for coating thickness measurement.

The right calibration makes the difference

Factors that can greatly influence measuring using the amplitude-sensitive eddy current method are the electrical conductivity, the shape and size of the test piece, and the roughness of the surface. In addition, the operator should always pay attention to the correct application for all measurements.

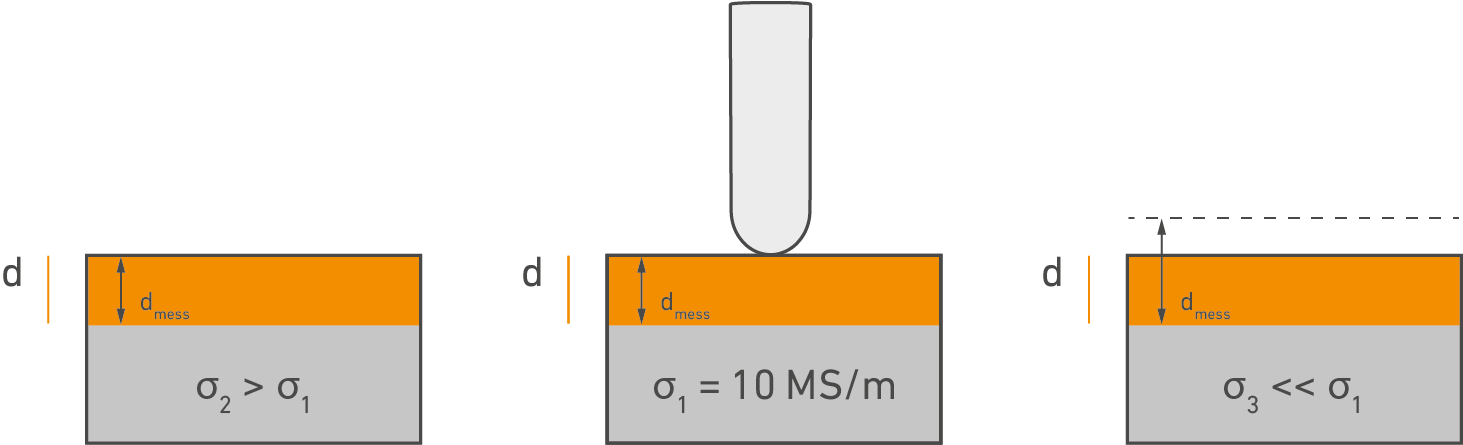

Electrical conductivity

Electrical conductivity influences how well an eddy current can be induced in a given material. Conductivity can vary greatly depending on the alloy and processing of a metal. In addition, it varies at different temperatures. To keep the adjustment effort low, our eddy current probes have conductivity compensation. They provide correct results over a wide range of conductivities.

Electrical conductivity

Electrical conductivityApplication on curved surfaces

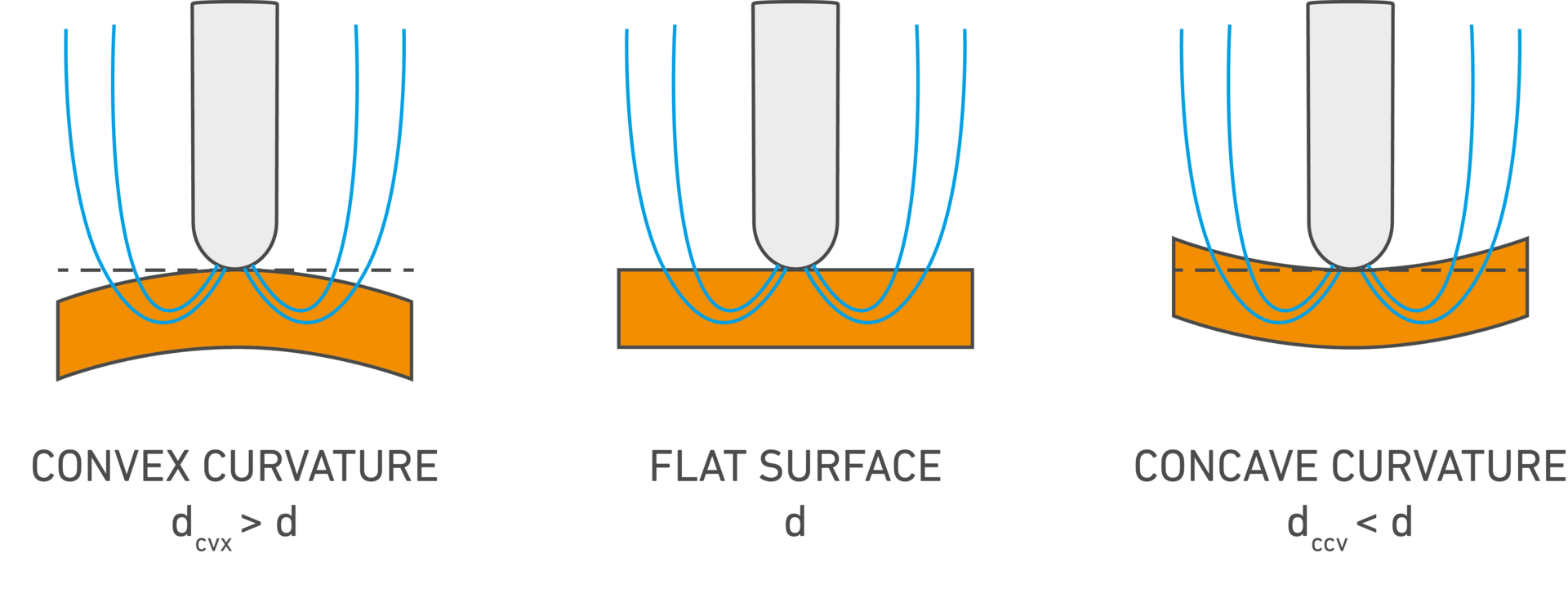

In practice, most measurement errors occur due to the shape of the test piece. With curved surfaces, the portion of the magnetic field that passes through the air changes. If a measuring device has been calibrated on a flat sheet, for example, this will result in measured values that are too low on a concave surface and thus result in coating thicknesses that are too thin. On a convex curvature, on the other hand, increased coating thicknesses are measured. The errors that occur in this way can be many times the actual value of the actual coating thickness.

The remedy here is careful calibration. But we have found a way to save time and labor here: a curvature-compensating probe. With this special probe, you can measure error-free on tubes from 2 mm radius, even if the instrument was calibrated on a flat sheet.

Application on curved surfaces

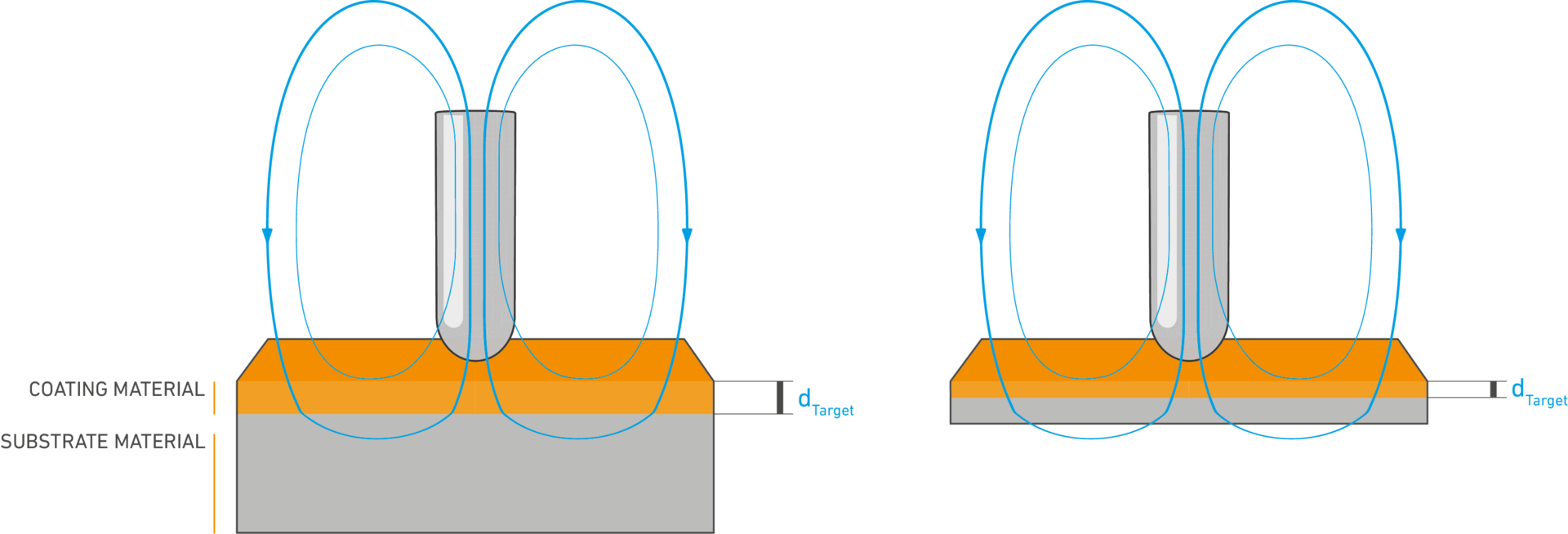

Application on curved surfacesApplication for small, flat parts

A similar effect can occur if the test part is small or very thin. In this case, too, the magnetic field reaches beyond the test part and partially runs in the air, which systematically falsifies the measurement results. To avoid these errors, you should always calibrate on an uncoated part that corresponds to your end product, if possible. This way, your coating thickness gauge will quickly provide reliable data on the thickness of the coating.

Application for small, flat parts

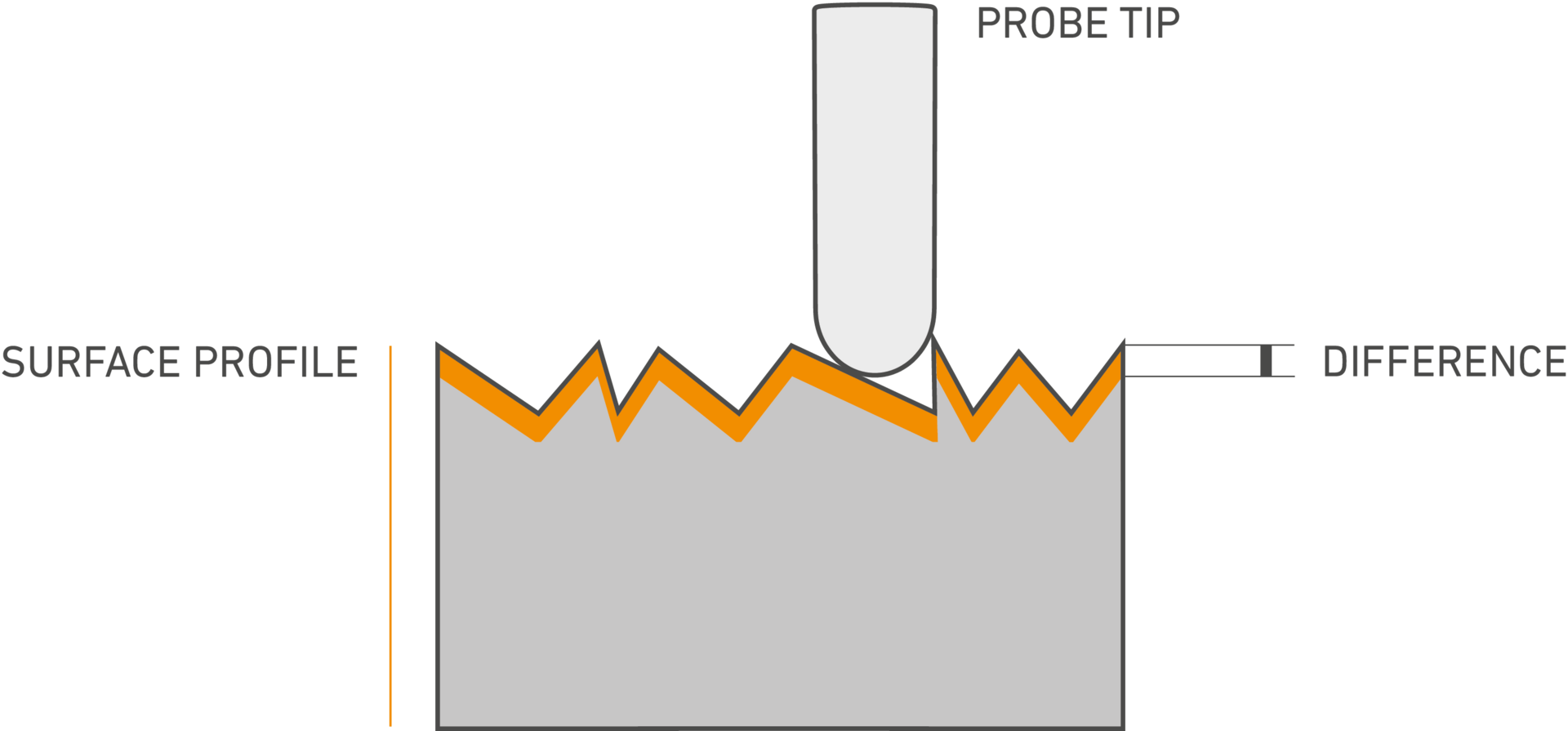

Application for small, flat partsRough surfaces

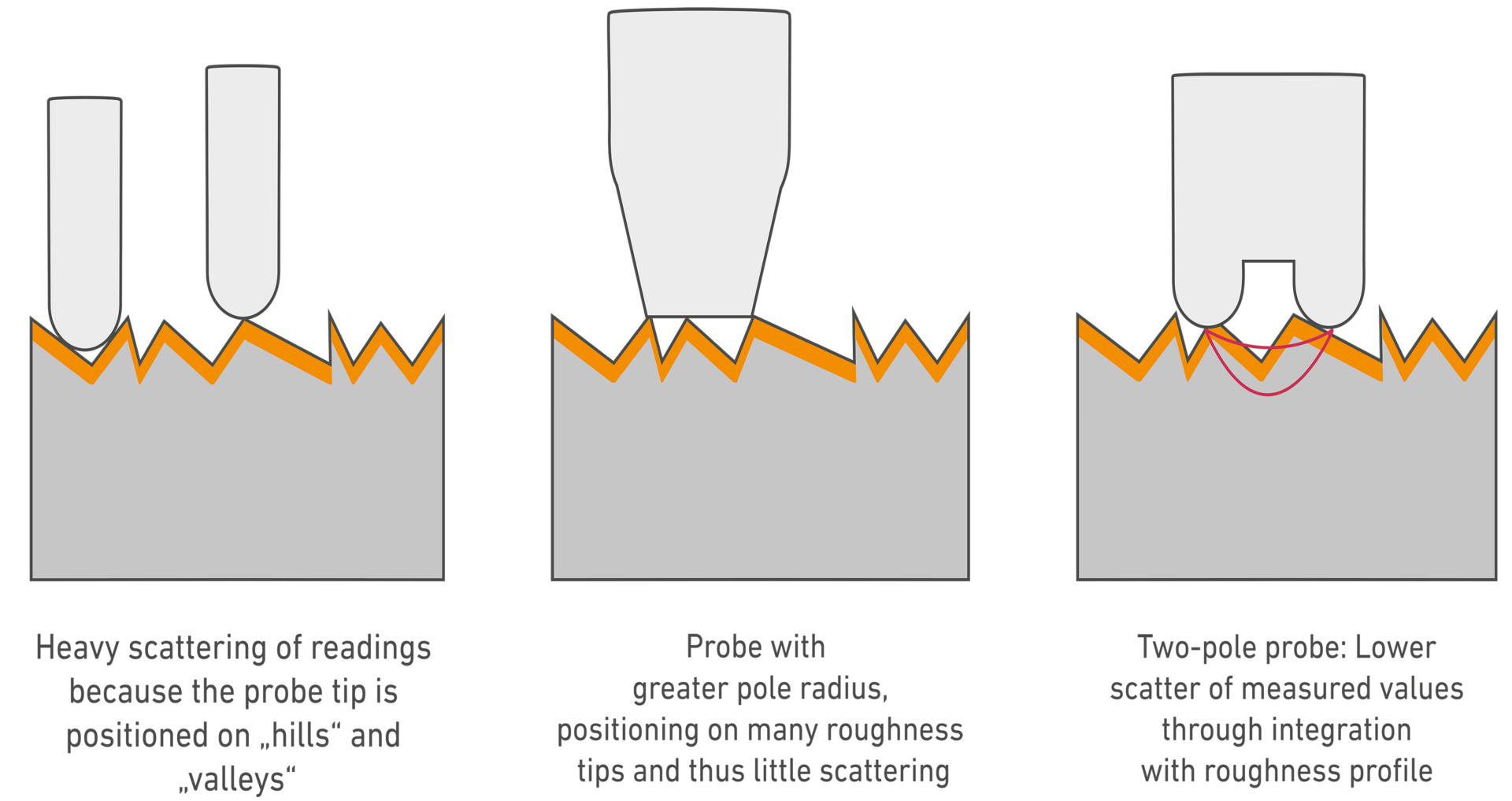

For rough surfaces, the result of the coating thickness measurement can vary greatly depending on whether the probe pole is placed in the valley or on a peak of the roughness profile. With such measuring, the results scatter and so we recommend making several repeat measurements to be able to form a stable average value. In general, coating thickness measurement on rough surfaces is only effective if the coating thickness is at least twice as high as the roughness peaks. This is the only way to measure the coating thickness without errors.

For better accuracy, we offer probes with extra large poles as well as 2-pole probes that integrate over roughness profiles to reduce measurement scatter.

Coating thickness measurement for rough surfaces

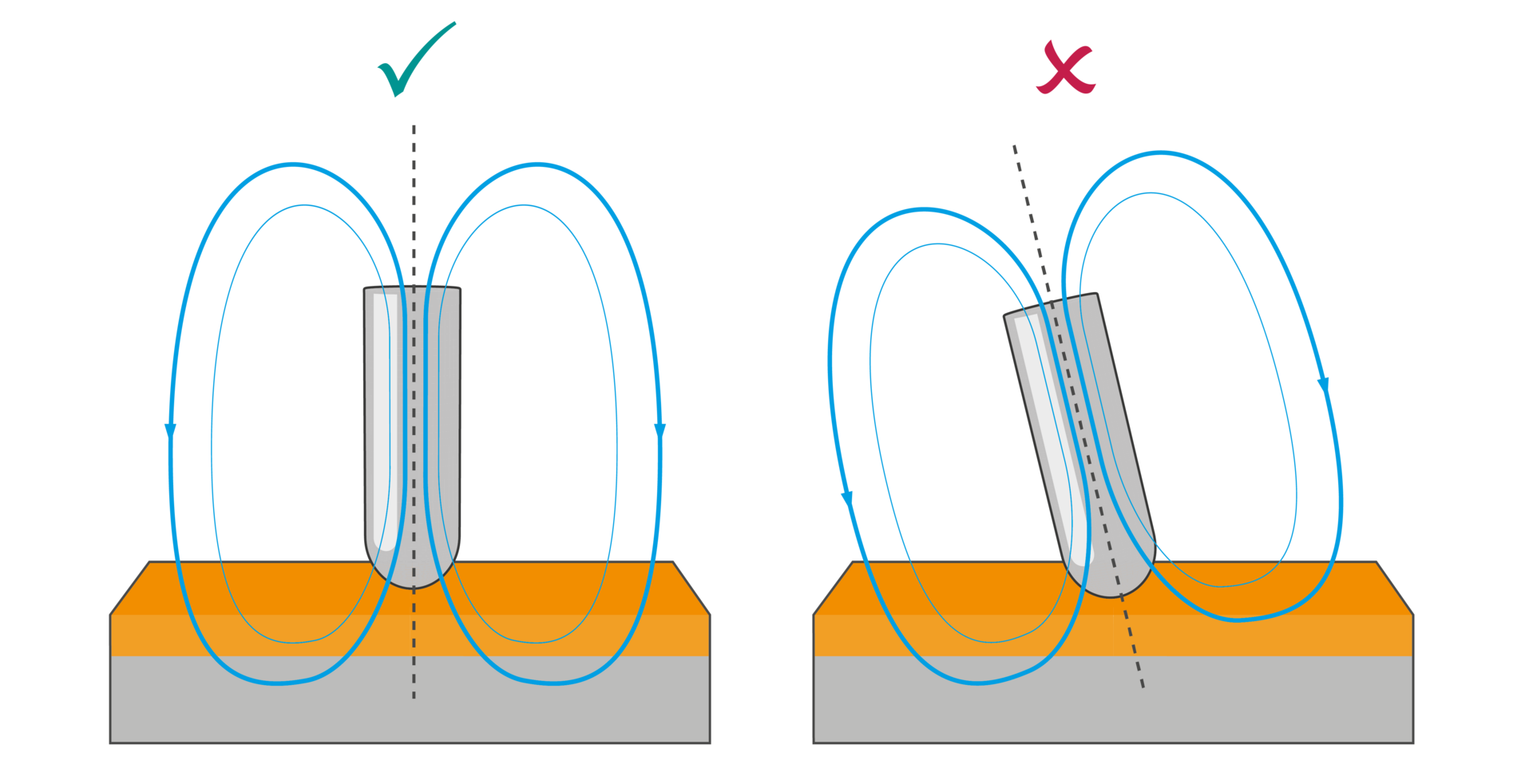

Coating thickness measurement for rough surfacesOperation of the coating thickness gauge

When determining coating thickness, properly operating the coating thickness gauge is of crucial importance. Always make sure the probe is held level above the coating surface and applied without pressure. The smaller the probe pole, the less the influence due to tilting. If the probe pole is large or flat, the influence is correspondingly greater. For better accuracy, a tripod can also be used to lower the probe onto the test part. In addition, we offer mounting aids for various probes, such as prisms for curved surfaces.

Principle: Calibration is always performed on the uncoated part on the measuring surface on which the coating thickness is later measured.

Operation of the coating thickness gauge

Operation of the coating thickness gauge

Important

To counteract erroneous measurement results, the following influences must also be taken into account:

- Indentation errors with particularly soft coatings (such as phosphate coatings).

- Scatter increases due to wear of the probe pole. We recommend carrying out regular checks.

Which standard is applied here?

Amplitude-sensitive eddy current method according to DIN EN ISO 2360