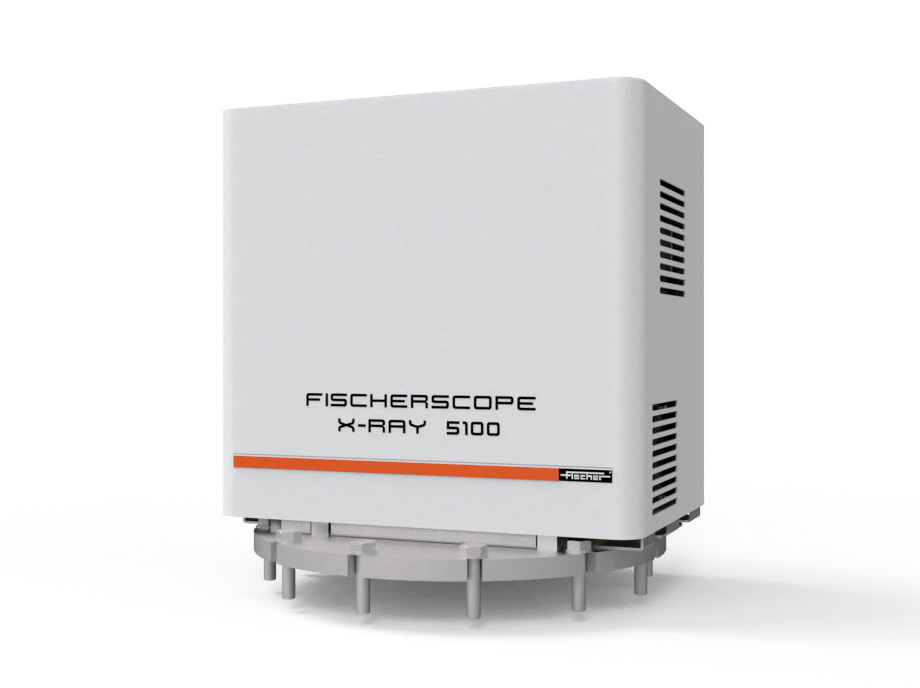

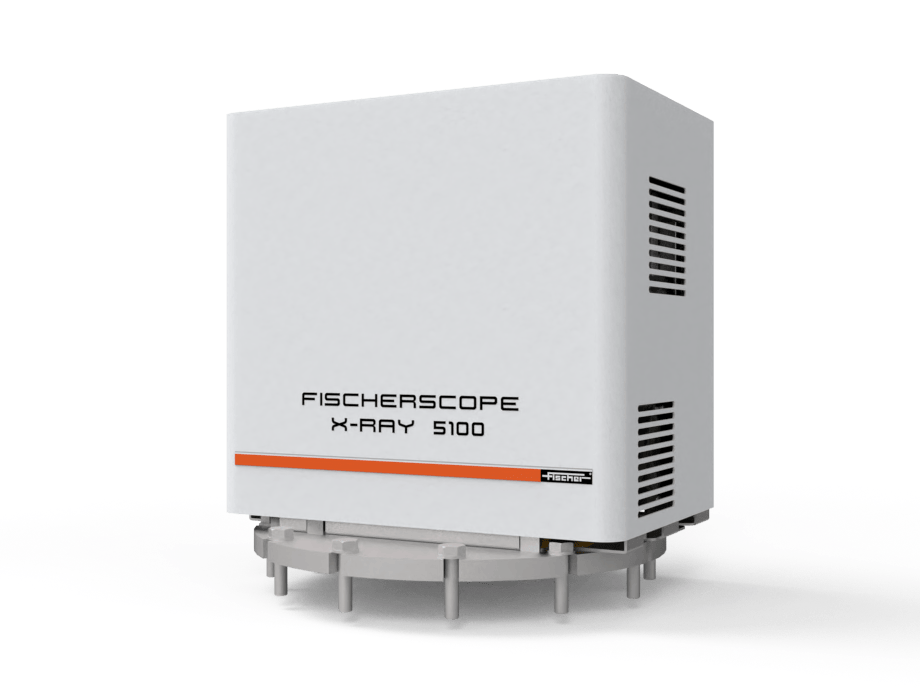

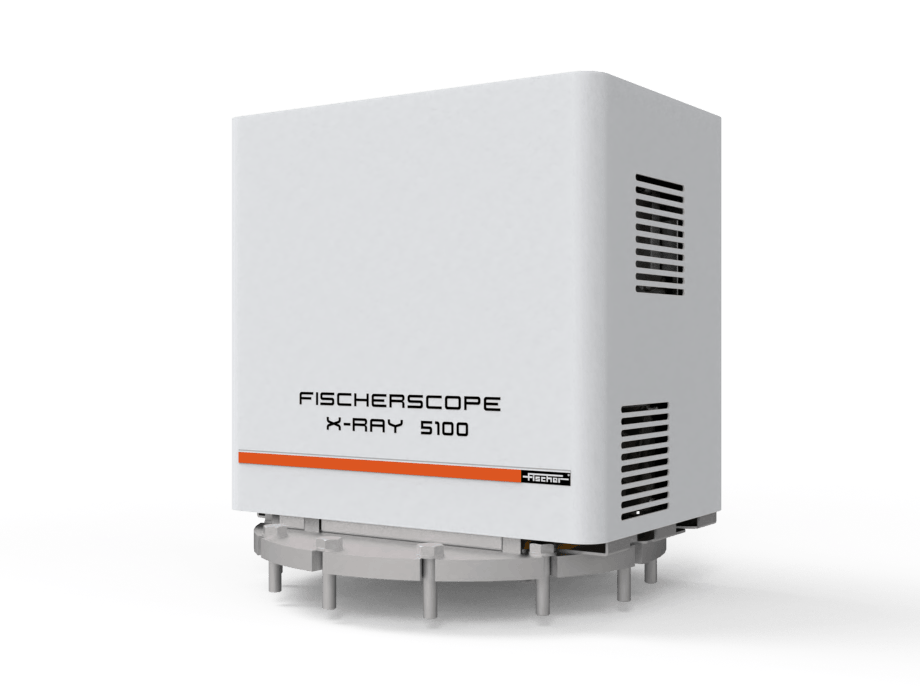

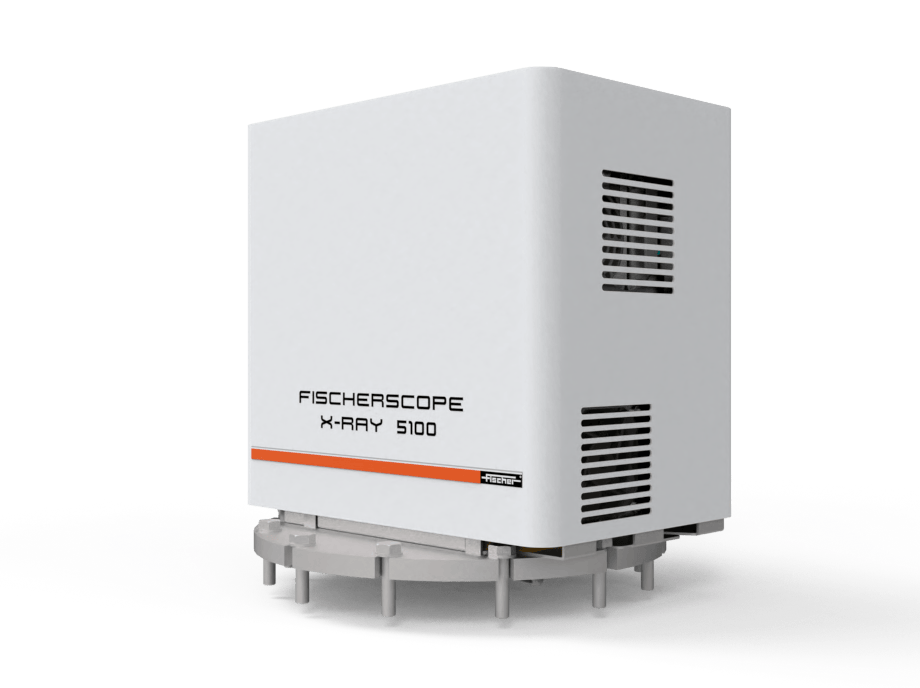

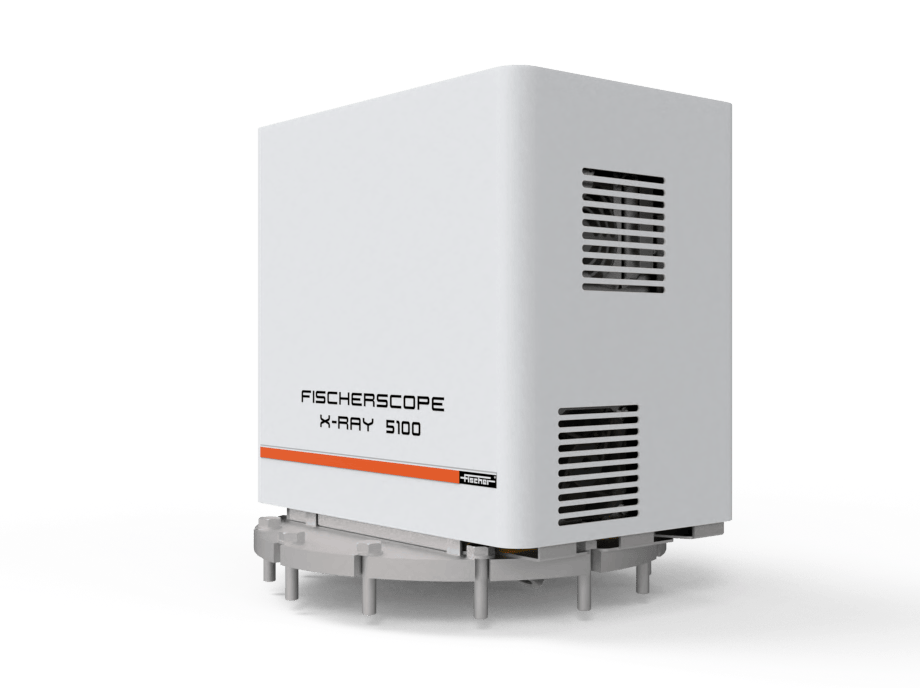

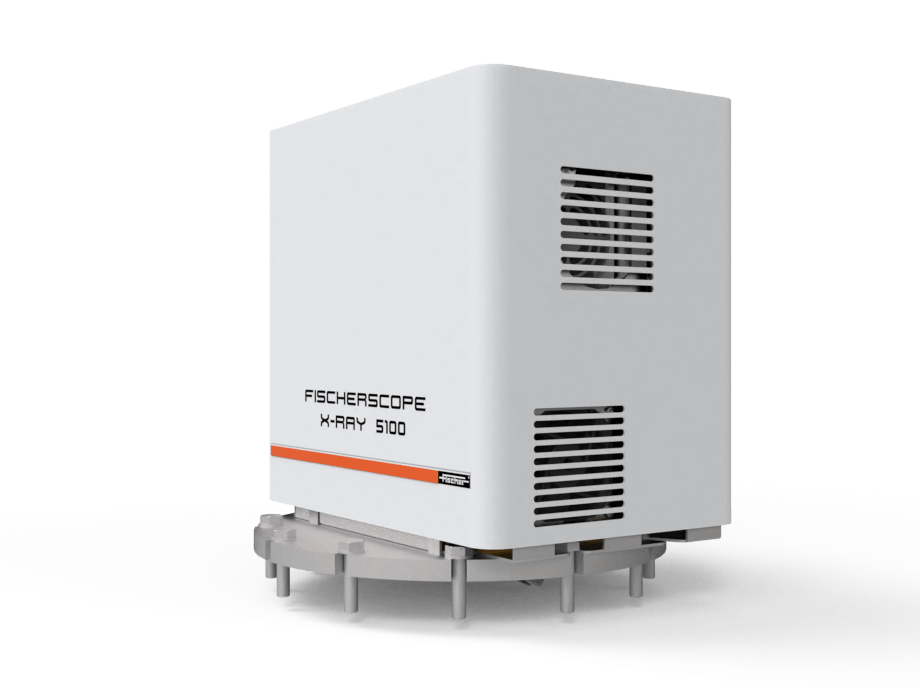

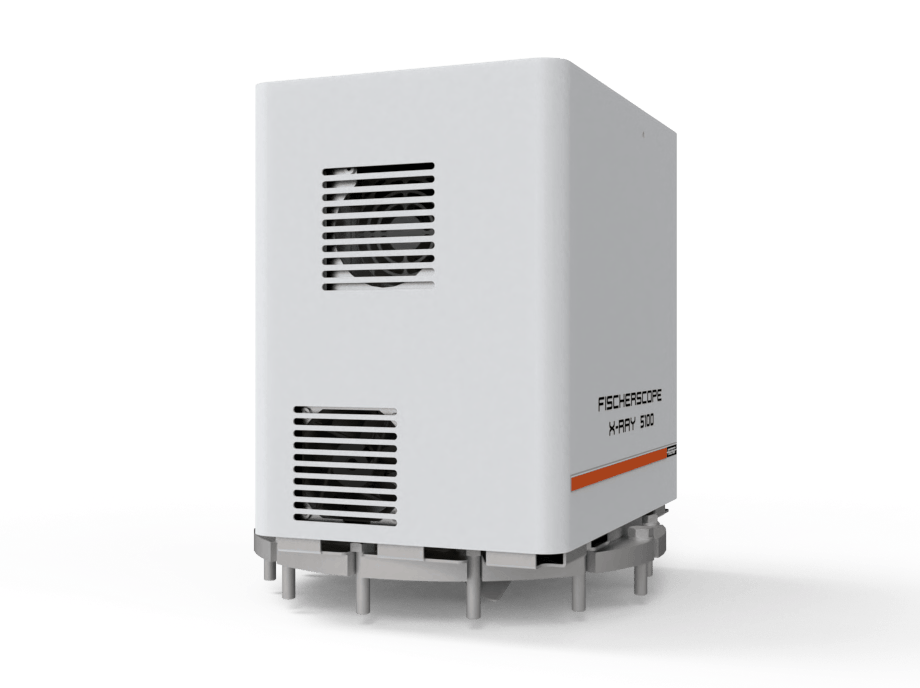

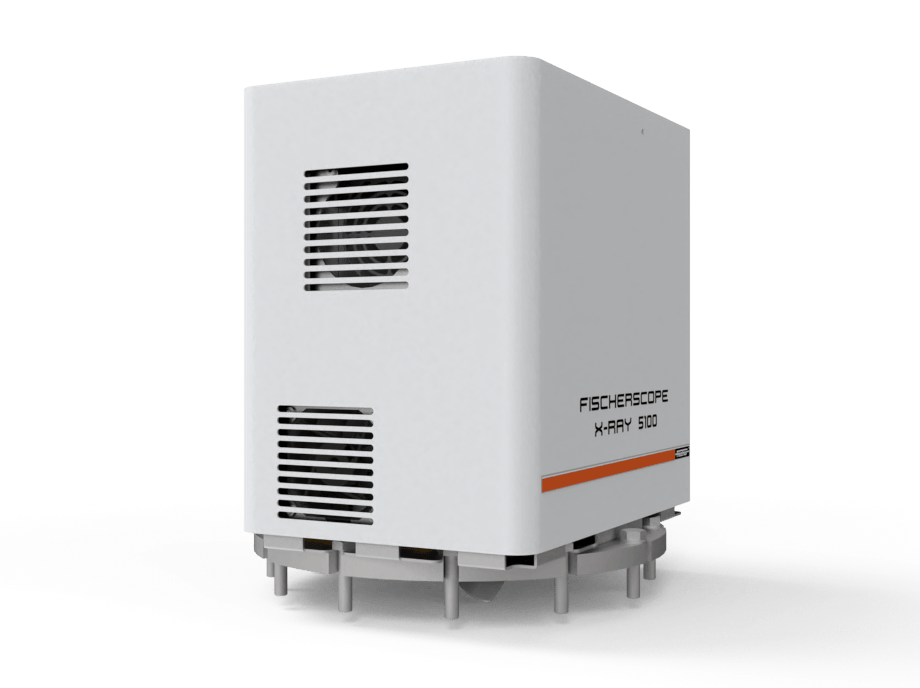

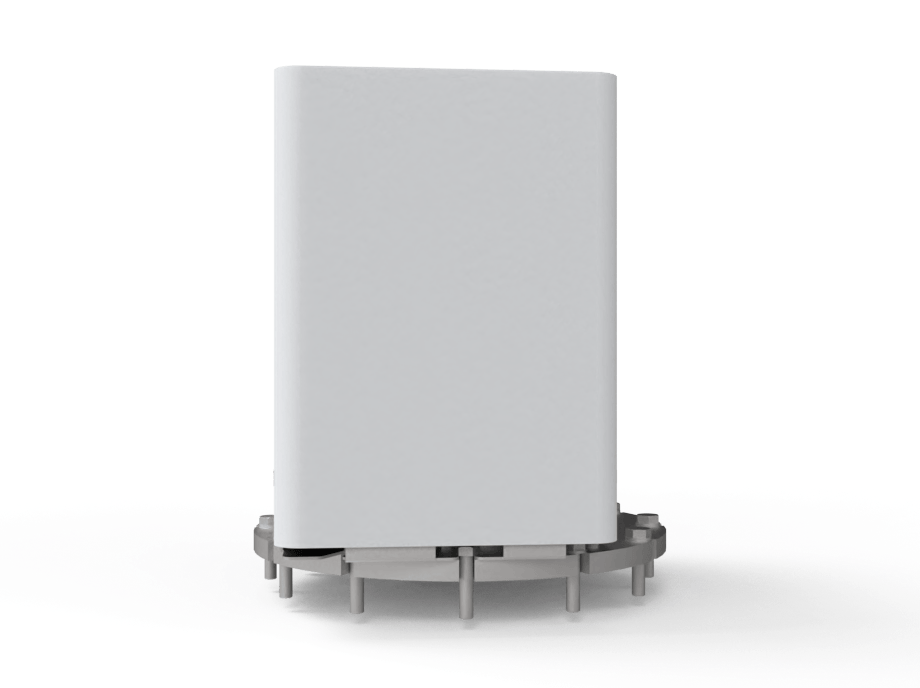

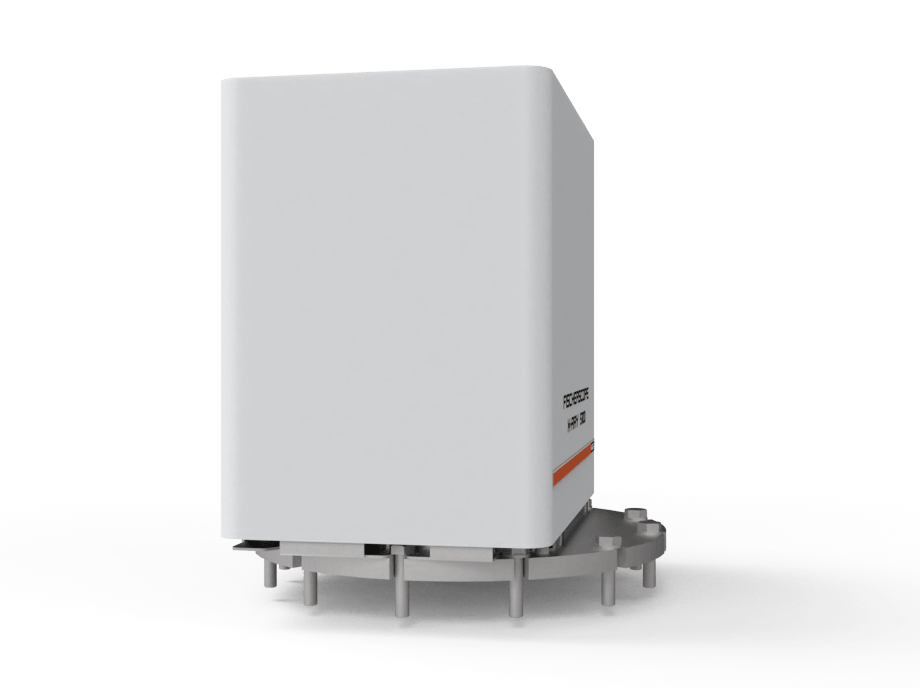

FISCHERSCOPE® X-RAY 5000

performance thanks to DPP+

through immovable parts

or in the air

¹ Significantly improved standard deviation and thus gauge capability or significantly reduced measurement time compared DPP to DPP+.

² Only FISCHERSCOPE® X-RAY 5400.

Continuous and smart quality control.

Designed for maximum uptime, the FISCHERSCOPE® X-RAY 5000 series convinces among other things with a high degree of customization and outstanding measurement performance - non-contact, non-destructive and precise. The devices of this series form modular units, which is why they can be easily installed as pure components in an existing plant.

Tailor-made.

Easy integration, individually adaptable to your application

Does not break a sweat.

Sample temperatures up to 250 °C (482 °F) thanks to water cooling

DPP+ digital pulse processor.

Shorter measuring times or improvement of standard deviation*

*compared to the DPP

Robust and reliable.

No moving parts

Compact design.

Measuring head with all necessary components in one unit

Vacuum compatible.

Can be mounted on vacuum chambers

Features

Microfocus tube with tungsten anode; molybdenum anode optional

Fixed aperture (configurable up to Ø 11 mm)

For measuring in vacuum or in the air

Optionally with water cooling for sample temperatures up to 250 °C

Silicon drift detector 50 mm² for highest precision

Fixed filter (configurable)

Peltier cooling

Higher count rates and significantly reduced measurement times thanks to DPP+

Any installation position possible

Remote control and data export via TCP/IP interface

Application examples

- Measuring thin coatings and low loadings on large-area products and substrates, such as fuel cells, on glass panels and very hot surfaces

- Monitoring the composition and thickness of layers in photovoltaics such as CIGS, CIS, CdTe and CdS

- Measuring thin layers of a few µm on metal strips, metal foils and plastic films

- Process monitoring of sputtering and electroplating equipment

You have further applications? Then contact us!