DMP®10-40 series

all-aluminum housing and IP64

light, sound and vibration ¹

exchangeable battery

¹ Vibrating alarm available for DUALSCOPE® DMP®40, DELTASCOPE® DMP®30 and ISOSCOPE® DMP®30.

The next level of tactile coating thickness measurement.

The compact handheld gauges of the DMP® family are versatile and can be used for a wide range of applications, especially in quality assurance. With a robust and ergonomic design, extensive functions and a wide range of probes, these flexible devices are the perfect solution for tactile and non-destructive coating thickness measurement of ferrous and non-ferrous base materials.

Built to last.

Next level quality and durability thanks to all-aluminum housing

Digital probes.

Fully digitized probes for the most demanding measurement tasks

Backward compatible.

Use all of your existing Fischer probes thanks to exchangeable adapter

Perfect fit.

Measure 24/7 due to quick and easy battery change

Full measuring control.

Feedback via light, sound and vibration whether measured values are within tolerance

Powerful software.

Automatic device recognition, easy data export and comprehensive reporting

Features

Test method: Magnetic induction and amplitude-sensitive eddy current method

Digital probes available for a wide range of applications, analog probes backwards compatible thanks to F-adapter

Measuring range: Depending on the combination of coating and base material and the used probe

Automatic device detection and easy data transfer via USB-C and Bluetooth, depending on the device

Measured value memory: 10,000 in one batch or 250,000 in 2,500 batches, depending on the device

Robust aluminum housing with protection class IP64

Most powerful software in tactile coating thickness measurement: Tactile Suite®

Replaceable Li-Ion battery for > 24 h operating time

Limit monitoring via light, sound and vibration, depending on the device

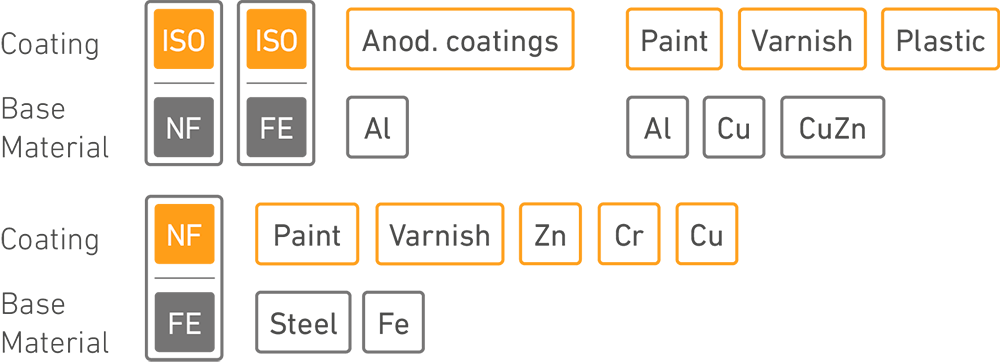

Overview of the DMP® series and application examples

Measuring method:

Amplitude-sensitive eddy current method and magnetic inductive measuring method

Applications:

Measurement of non-magnetic or electrically non-conductive coatings on magnetic or non-magnetic, electrically conductive base materials

Application examples:

- ISO on NF: Paint, lacquer or plastic coatings on Al, Cu, CuZn

- ISO on NF: Anodized layers on Al

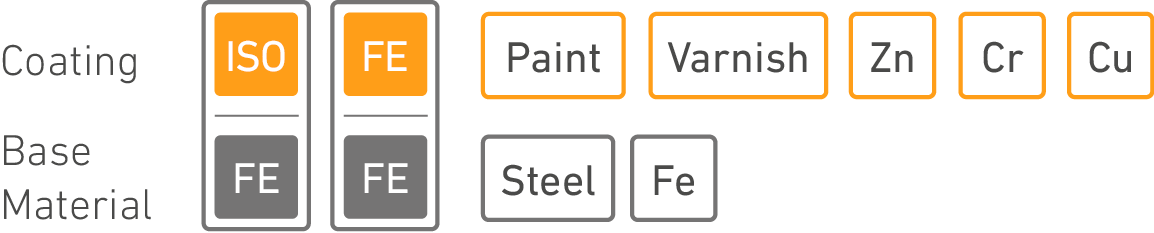

- ISO on FE: Paint, lacquer, plastic coatings on Fe, steel

- NFE on FE: Zn, Cr, Cu on Fe, steel

Do you have other applications? Then contact us!

Measuring method:

Amplitude-sensitive eddy current method

Applications:

Measurement of electrically insulating coatings on non-magnetic, electrically conductive metals

Application examples:

- ISO on NF: Paint, lacquer or plastic coatings on Al, Cu, CuZn

- ISO on NF: Anodized layers on Al

Do you have other applications? Then contact us!

Measuring method:

Magnetic inductive measuring method

Applications:

Measurement of non-magnetic coatings on magnetic base materials

Application examples:

- ISO on FE: Paint, lacquer, plastic coatings on Fe, steel

- NF on FE: Zn, Cr, Cu on Fe, steel

Do you have other applications? Then contact us!

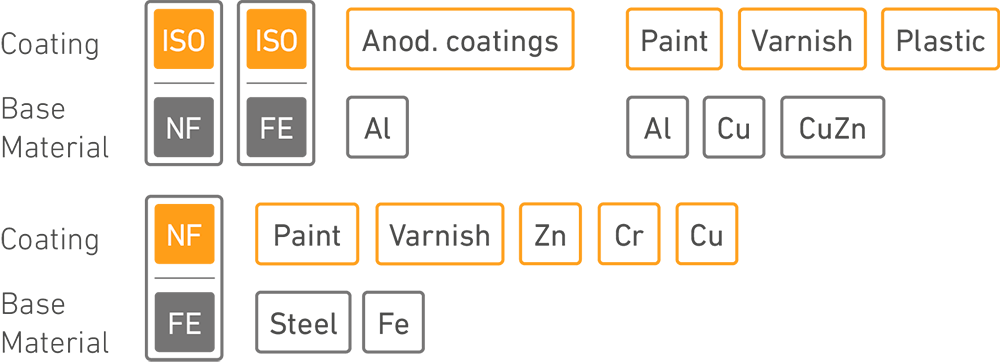

DUALSCOPE® DMP®

- ISO on NF: Paint, lacquer or plastic coatings on Al, Cu, CuZn

- ISO on NF: Anodized layers on Al

- ISO on FE: Paint, lacquer, plastic coatings on Fe, steel

- NFE on FE: Zn, Cr, Cu on Fe, steel

Measuring method:

Amplitude-sensitive eddy current method and magnetic inductive measuring method

Applications:

Measurement of non-magnetic or electrically non-conductive coatings on magnetic or non-magnetic, electrically conductive base materials

Application examples:

Do you have other applications? Then contact us!

ISOSCOPE® DMP®

- ISO on NF: Paint, lacquer or plastic coatings on Al, Cu, CuZn

- ISO on NF: Anodized layers on Al

Measuring method:

Amplitude-sensitive eddy current method

Applications:

Measurement of electrically insulating coatings on non-magnetic, electrically conductive metals

Application examples:

Do you have other applications? Then contact us!

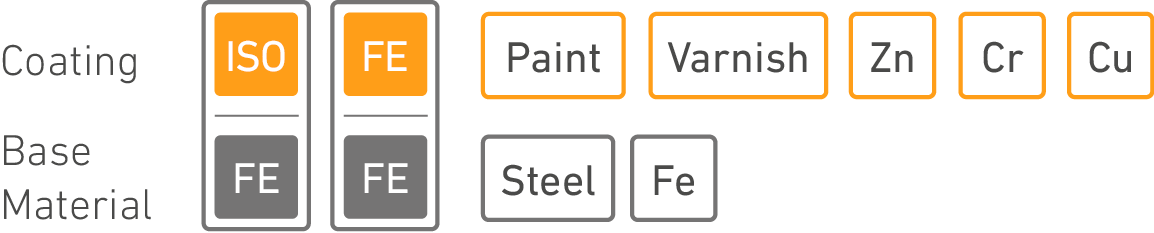

DELTASCOPE® DMP®

- ISO on FE: Paint, lacquer, plastic coatings on Fe, steel

- NF on FE: Zn, Cr, Cu on Fe, steel

Measuring method:

Magnetic inductive measuring method

Applications:

Measurement of non-magnetic coatings on magnetic base materials

Application examples:

Do you have other applications? Then contact us!

Model differences in detail

- Paint, lacquer or plastic coatings on aluminum, copper or brass (ISO/NF)

- Anodized coatings on aluminium (ISO/NF)

- Zinc, chrome, copper coatings on steel or iron (NF/FE)

- Paint, lacquer, plastic coatings on steel or iron (ISO/FE)

- Zinc, chrome, copper coatings on steel or iron (NF/FE)

- Paint, lacquer, plastic coatings on steel or iron (ISO/FE)

- Paint, lacquer or plastic coatings on aluminum, copper or brass (ISO/NF)

- Anodized coatings on aluminium (ISO/NF)

- Paint, lacquer or plastic coatings on aluminum, copper or brass (ISO/NF)

- Anodized coatings on aluminium (ISO/NF)

- Zinc, chrome, copper coatings on steel or iron (NF/FE)

- Paint, lacquer, plastic coatings on steel or iron (ISO/FE)

- Zinc, chrome, copper coatings on steel or iron (NF/FE)

- Paint, lacquer, plastic coatings on steel or iron (ISO/FE)

- Paint, lacquer or plastic coatings on aluminum, copper or brass (ISO/NF)

- Anodized coatings on aluminium (ISO/NF)

DUALSCOPE® DELTASCOPE® ISOSCOPE® Model DUALSCOPE®

DMP®20

"Entry-level model"DUALSCOPE®

DMP®40

"Comfort model"DELTASCOPE®

DMP®10

"Entry-level model"DELTASCOPE®

DMP®30

"Comfort model"ISOSCOPE®

DMP®10

"Entry-level model"ISOSCOPE®

DMP®30

"Comfort model"Application Measurement of non-magnetic or electrically non-conductive coatings on magnetic or non-magnetic, electrically conductive base materials Measurement of non-magnetic coatings on magnetic base materials Measurement of electrically insulating coatings on non-magnetic, electrically conductive metals Base material Non-ferrous metal (NF) and steel or iron (FE) Steel or iron (FE) Non-ferrous metal (NF) Application examples Measuring method Amplitude-sensitive eddy current method AND Magnetic inductive measuring method Magnetic inductive measuring method Amplitude-sensitive eddy current method Measured value memory ≤ 10,000 ≤ 250,000 ≤ 10,000 ≤ 250,000 ≤ 10,000 ≤ 250,000 Number of measuring tasks 1 ≤ 2,500 1 ≤ 2,500 1 ≤ 2,500 Communication USB-C USB-C and Bluetooth USB-C USB-C and Bluetooth USB-C USB-C and Bluetooth Limit value monitoring Light and sound Light, sound and vibration Light and sound Light, sound and vibration Light and sound Light, sound and vibration Standards DIN EN ISO 2178, DIN EN ISO 2360, ASTM D7091, ASTM 4471 DIN EN ISO 2178, ASTM D7091, ASTM 4471 DIN EN ISO 2360, ASTM D7091, ASTM 4471 DUALSCOPE®Model DUALSCOPE®

DMP®20

"Entry-level model"DUALSCOPE®

DMP®40

"Comfort model"Application Measurement of non-magnetic or electrically non-conductive coatings on magnetic or non-magnetic, electrically conductive base materials Base material Non-ferrous metal (NF) and steel or iron (FE) Application examples Measuring method Amplitude-sensitive eddy current method AND Magnetic inductive measuring method Measured value memory ≤ 10,000 ≤ 250,000 Number of measuring tasks 1 ≤ 2,500 Communication USB-C USB-C and Bluetooth Limit value monitoring Light and sound Light, sound and vibration Standards DIN EN ISO 2178, DIN EN ISO 2360, ASTM D7091, ASTM 4471 DELTASCOPE®Model DELTASCOPE®

DMP®10

"Entry-level model"DELTASCOPE®

DMP®30

"Comfort model"Application Measurement of non-magnetic coatings on magnetic base materials Base material Steel or iron (FE) Application examples Measuring method Magnetic inductive measuring method Measured value memory ≤ 10,000 ≤ 250,000 Number of measuring tasks 1 ≤ 2,500 Communication USB-C USB-C and Bluetooth Limit value monitoring Light and sound Light, sound and vibration Standards DIN EN ISO 2178, ASTM D7091, ASTM 4471 ISOSCOPE®Model ISOSCOPE®

DMP®10

"Entry-level model"ISOSCOPE®

DMP®30

"Comfort model"Application Measurement of electrically insulating coatings on non-magnetic, electrically conductive metals Base material Non-ferrous metal (NF) Application examples Measuring method Amplitude-sensitive eddy current method Measured value memory ≤ 10,000 ≤ 250,000 Number of measuring tasks 1 ≤ 2,500 Communication USB-C USB-C and Bluetooth Limit value monitoring Light and sound Light, sound and vibration Standards DIN EN ISO 2360, ASTM D7091, ASTM 4471

Application Notes

AN007 Thickness measurement of conformal coatings on printed circuit boards 0.99 MB AN020 Measurement of SAM (sprayable acoustic material) coatings for the automotive industry 0.47 MB AN023 Thickness measurement of INCONEL coatings on heat exchanger tubes 2.36 MB AN036 Measurement of cladding coatings with the FGB2 probe 0.81 MB AN040 Controlling the thickness of solder resist in the manufacture of printed circuit boards 0.94 MB AN046 Measurement of thick NiP coatings on automotive parts 0.78 MB AN066 Measuring lacquer coatings on rough surfaces 0.59 MB AN075 Measuring anti-fouling coatings on marine structures 1.05 MB AN077 Measuring the thickness of micaceous iron oxide coatings 1.03 MB AN084 Thickness of protective coatings on wristwatch dials 0.66 MB AN091 Different ways to achieve valid measurement values and optimize measurement performance 0.20 MB AN103 Measurement of coatings on non-ferrous metals and magnetizable metals with the dual probe D-FN 0.90 MBProduct videos

Tutorials

Webinars

Brochures