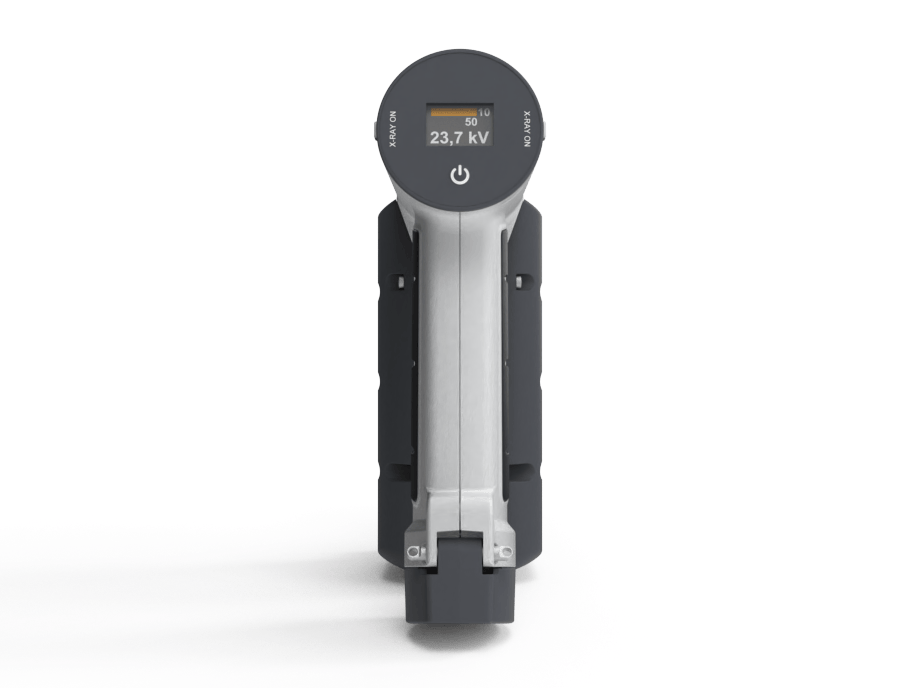

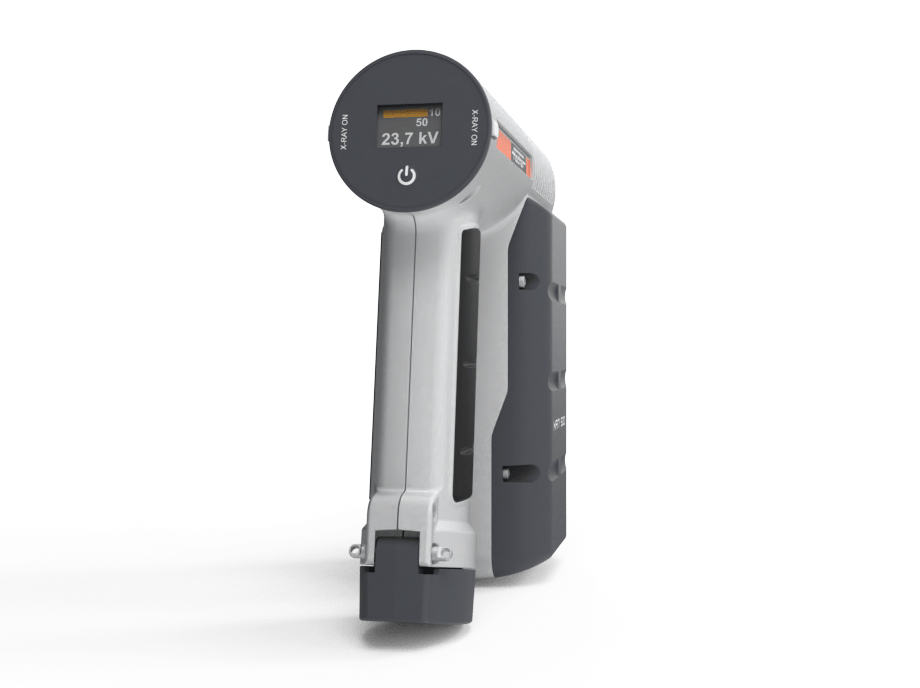

FISCHERSCOPE® X-RAY XAN® 500

composition in one measurement

for outdoor use

silicon drift detector

More versatile than any other.

The FISCHERSCOPE® X-RAY XAN® 500 is the most precise mobile XRF instrument on the market. The 3-point support ensures repeatable measurement results. It ensures that the instrument is always placed correctly and kept stable during measuring. The high-quality silicon drift detector (SDD) guarantees the necessary precision for analyzing multilayer coatings and alloy coatings such as zinc-nickel. The special feature of the compact measuring device: It detects the thickness and composition of the layer in parallel in just one measurement.

Two in one.

Mobile, universal instrument for coating thickness measurement and material analysis in laboratory quality

Mobile use.

Can be used flexibly indoors and outdoors

Precise and exact.

Three-point support and geometry enable secure contact with the sample

Full flexibility.

Variable measuring direction for measuring bulky objects or even small parts

Long operating time.

Battery charge lasts up to six hours of operation

Features

Silicon drift detector for highest precision on thin films

Three-point support and geometry enable safe placement on the sample

Measuring spot approx.: Ø 3 mm

Portable measuring box turns system into XRF tabletop unit

IP54 protection class for outdoor use

Determination of metal content in electroplating baths with corresponding accessories

Up to 6 h operating time with one battery charge

Weight: 1.9 kg

Application examples

- Simultaneous determination of coating thickness and composition with only one measurement (such as ZnNi on Fe)

- Standard-free measuring of unknown alloys

- Measuring of large coated parts, such as machine components and housings

- Testing of electroplated layers

- Analysis of metal content of electroplating baths

- Analysis of bulky objects and small parts using the measuring box

Do you have other applications? Then contact us!