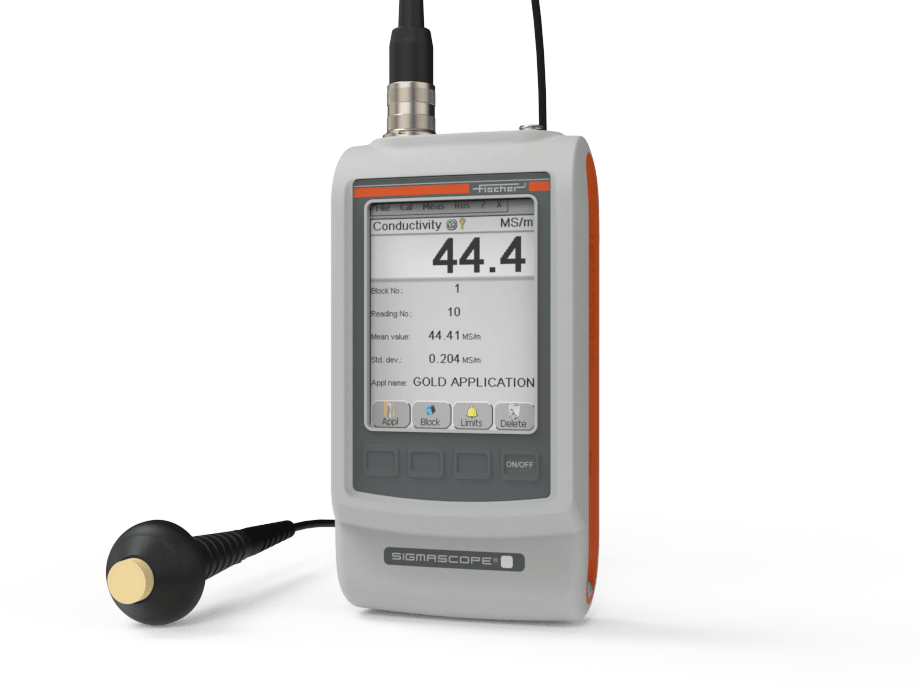

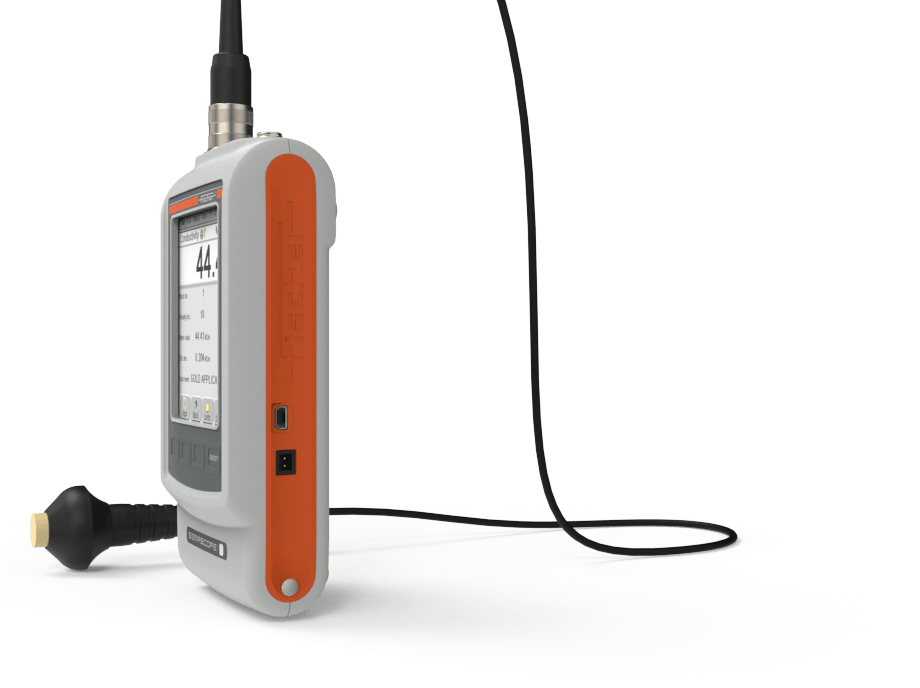

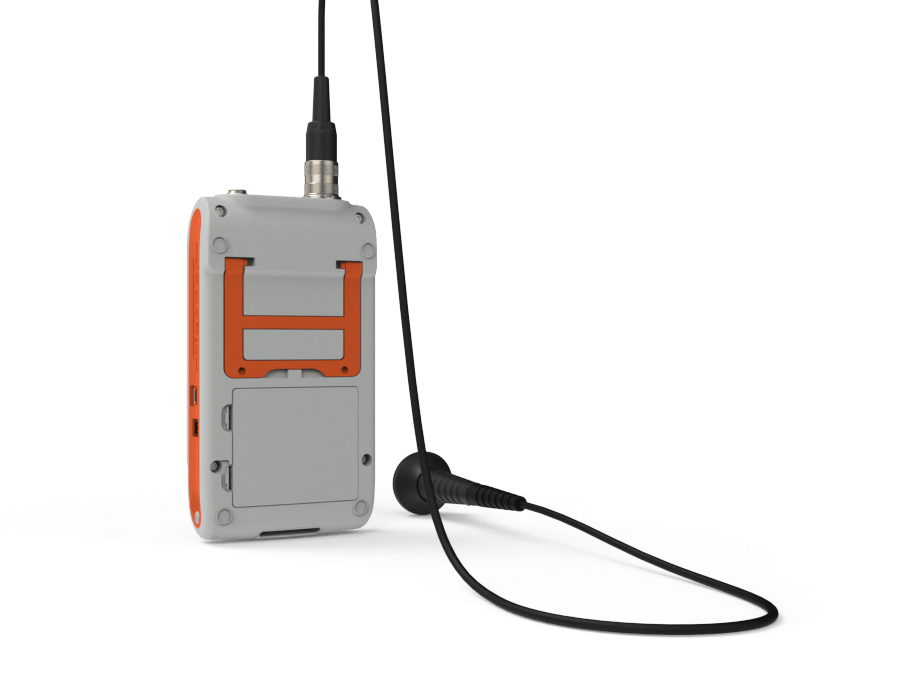

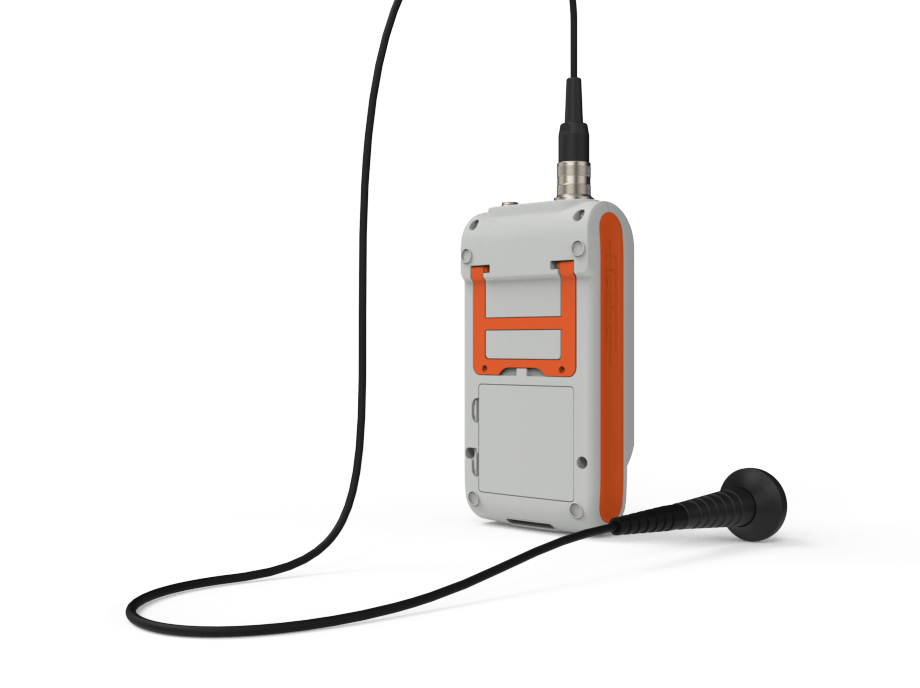

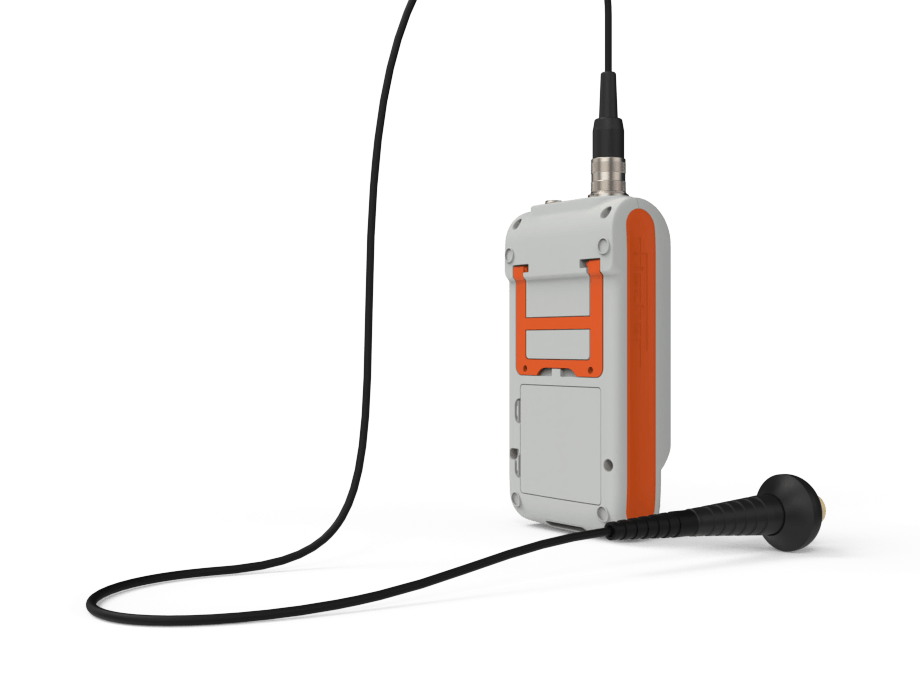

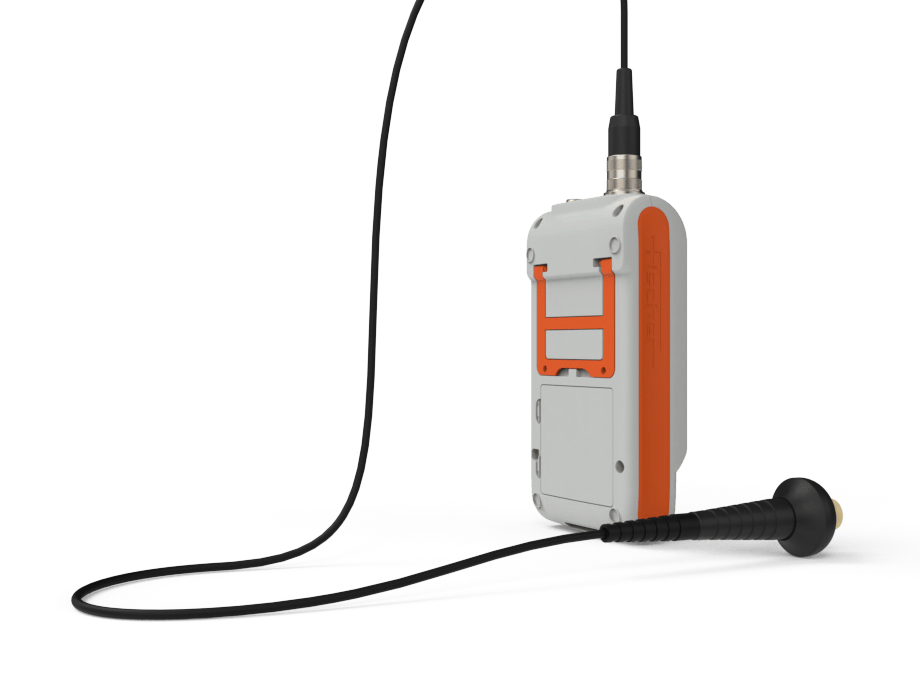

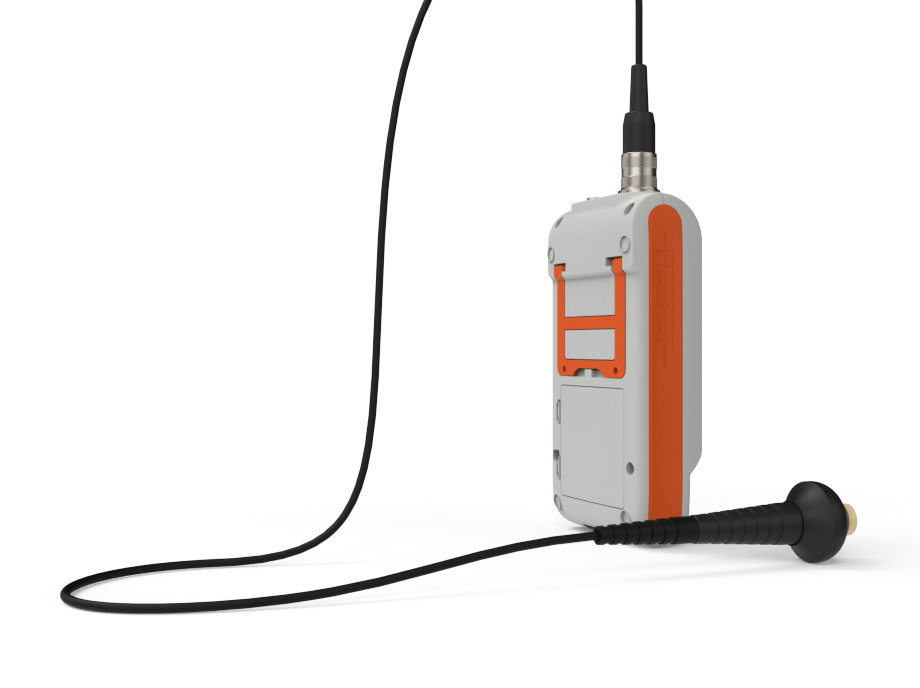

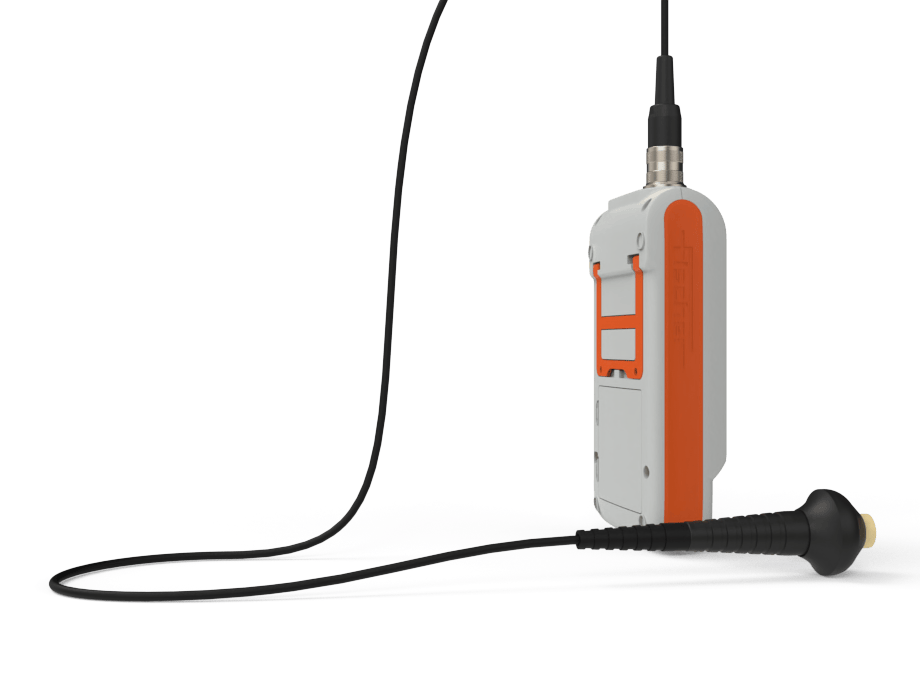

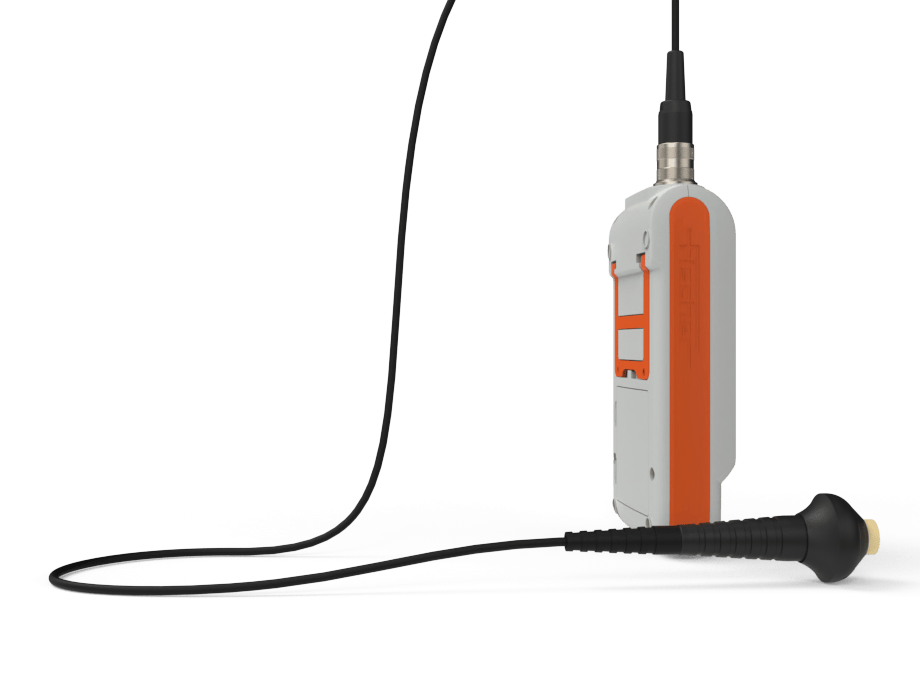

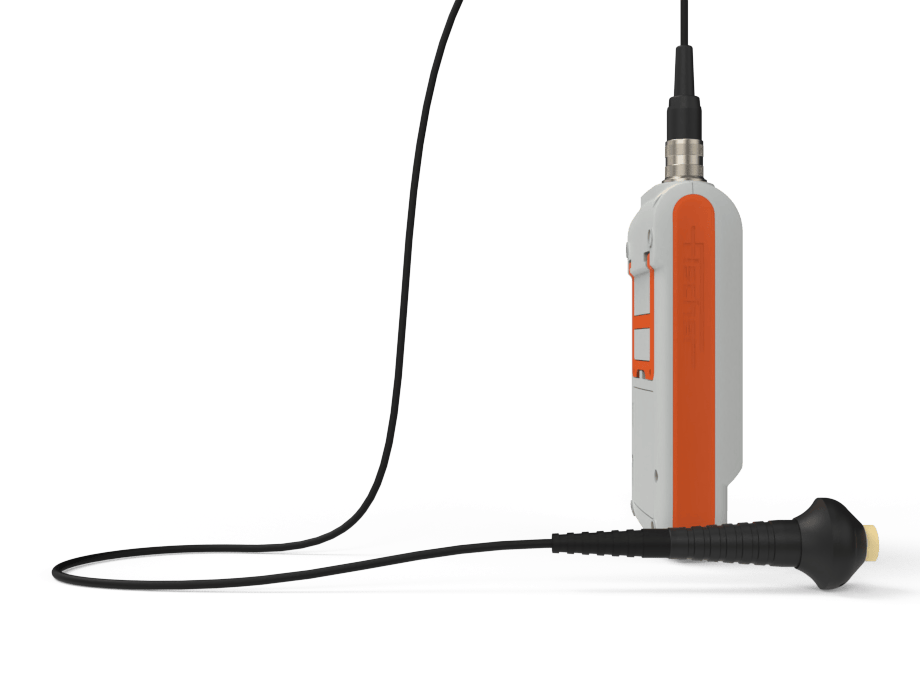

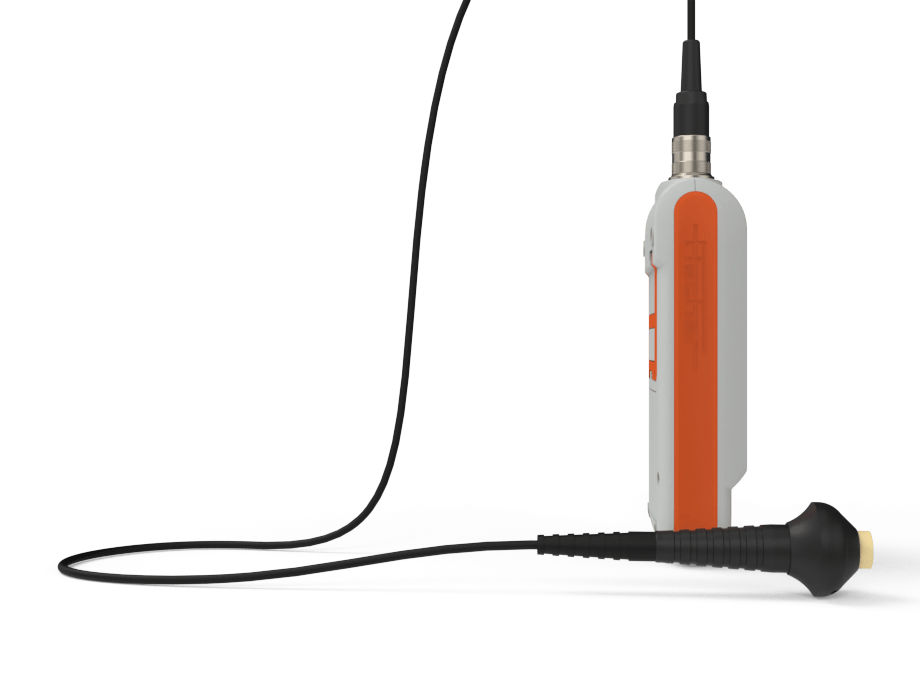

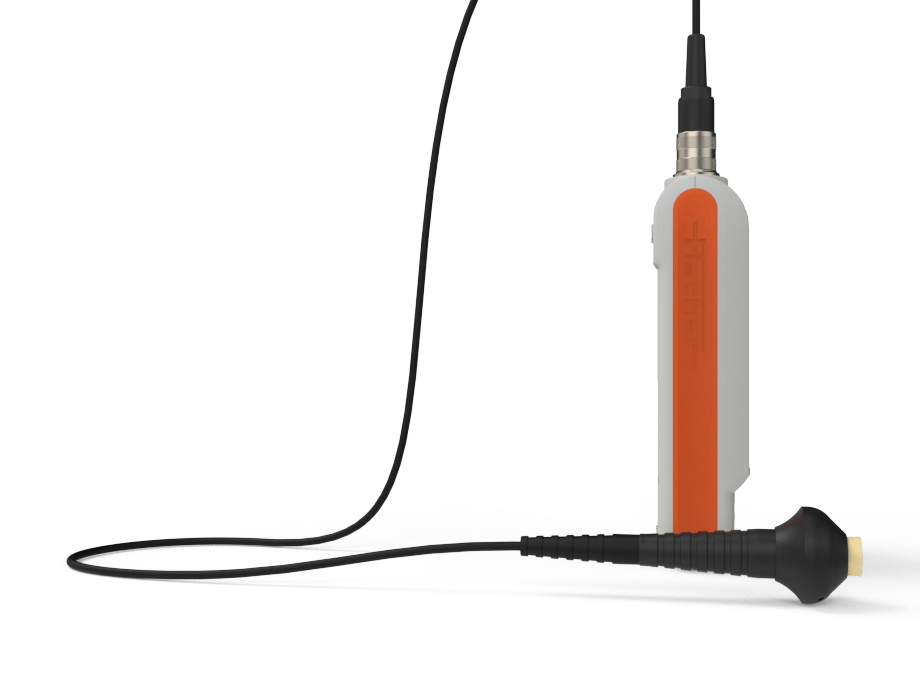

SIGMASCOPE® SMP350

thermal compensation

Boeing specification BAC 5651

repeatability

The solution for electrical conductivity measurement.

With the SIGMASCOPE® SMP350, you can measure the electrical conductivity of aluminum or the electrical conductivity of copper quickly, easily and accurately. You can also draw conclusions about the hardness and strength of heat-treated materials. This allows you to check the material stability of components that are exposed to strong temperature fluctuations. Heat damage and material fatigue can also be easily determined.

Perfect fit.

Different measuring frequencies for different penetration depths and measuring tasks

Always in view.

Clear management of measurement tasks through user-definable file and folder structure

Easy to use.

Operation via high-contrast touchscreen with intuitive user interface

Predestined for the aerospace industry.

Meets Boeing specification BAC 5651 with matching probe

Features

Measuring method: Phase-sensitive eddy current method

Conductivity measurement according to DIN 50994

Individual consideration of the temperature coefficient valid for each material (temperature sensor optionally available)

Measured value memory: For a large number of measurements

Extensive evaluation and statistics functions

Measuring range: 0.3 - 63 MS/m or 0.5 - 108 % IACS

Simple data transfer via USB interface

Limit value monitoring via sound

Probes available for a wide range of applications, with and without integrated temperature sensor

Application examples

- Conductivity testing of raw materials for sorting and quality assurance

- Testing of coin alloys, such as the conductivity of euro coins

- Evaluation of hardness and strength of heat-treated materials

- Checking for heat damage, material fatigue and cracks

- Estimation of the phosphorus content in copper alloys or copper-containing materials

- Tracking precipitation processes, such as in Cu-Cr alloys

- Checking the homogeneity of alloys

- Scrap sorting

Do you have other applications? Then contact us!