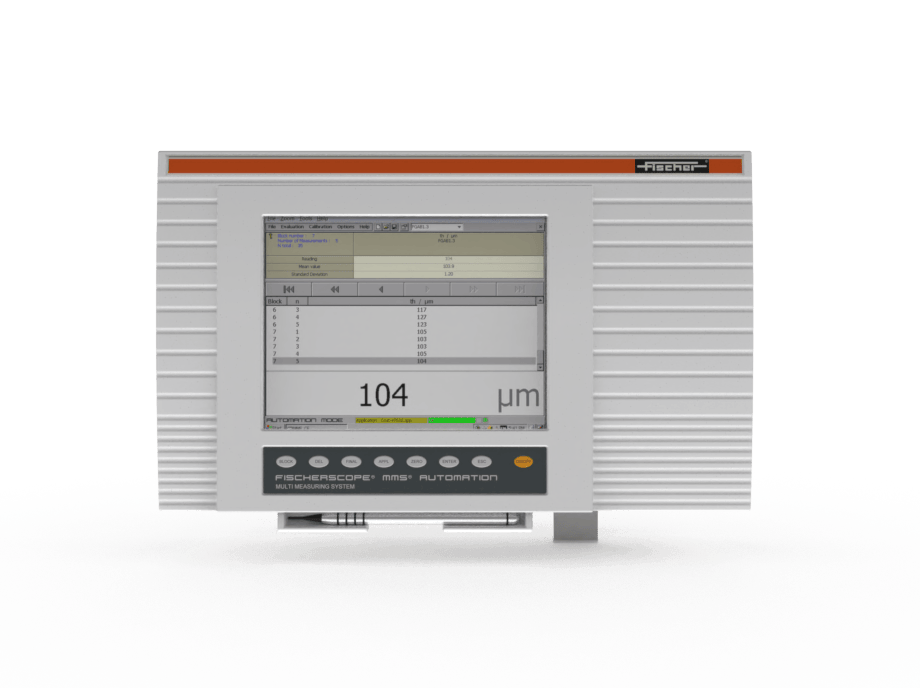

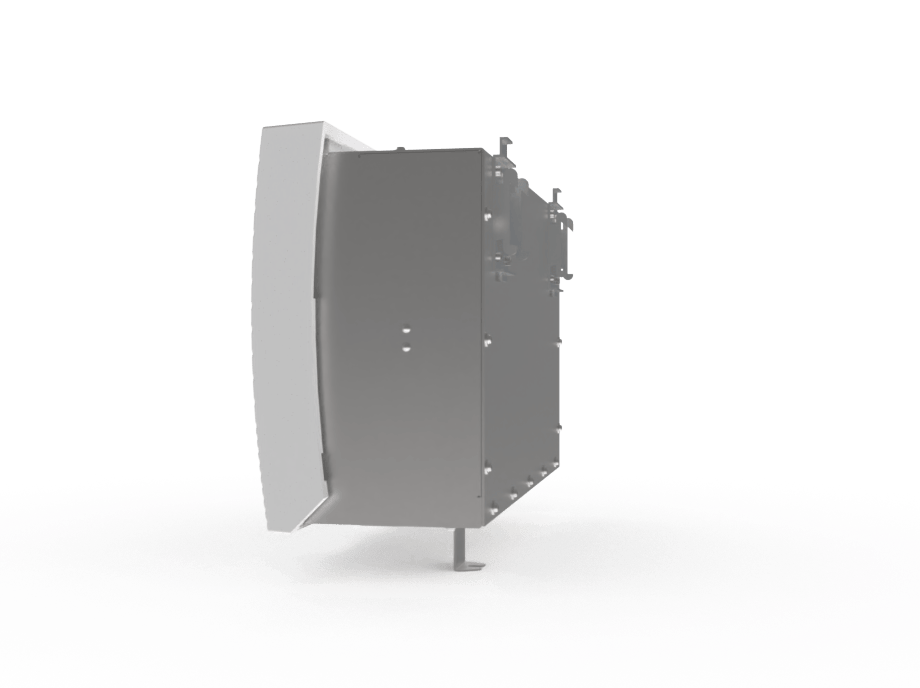

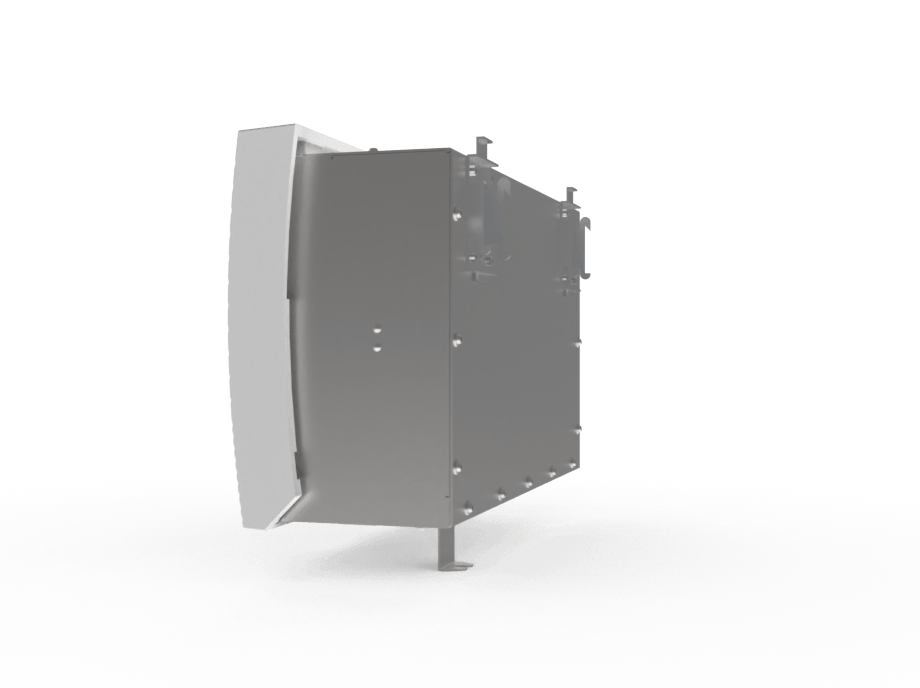

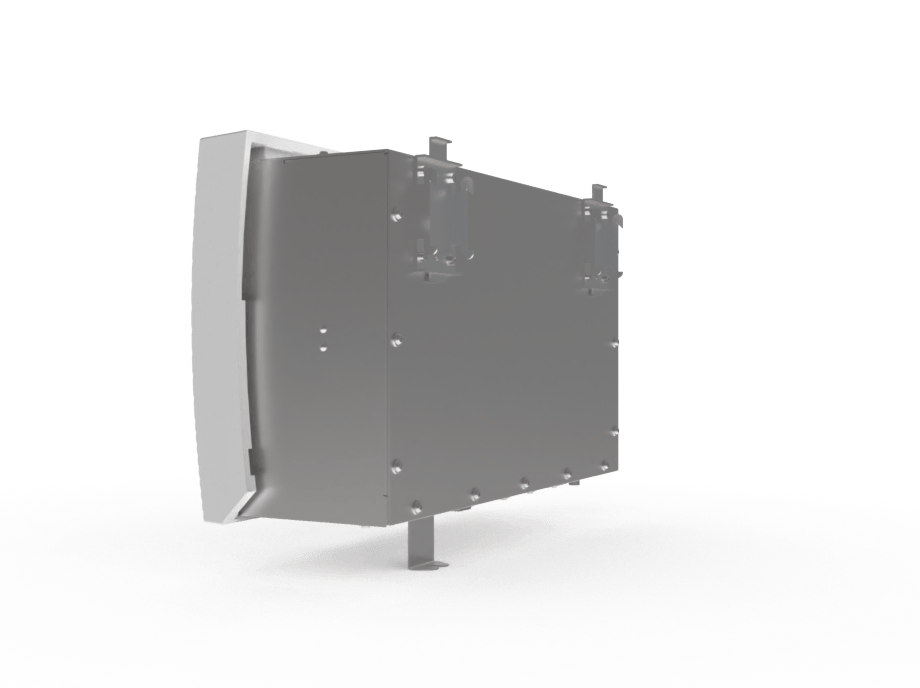

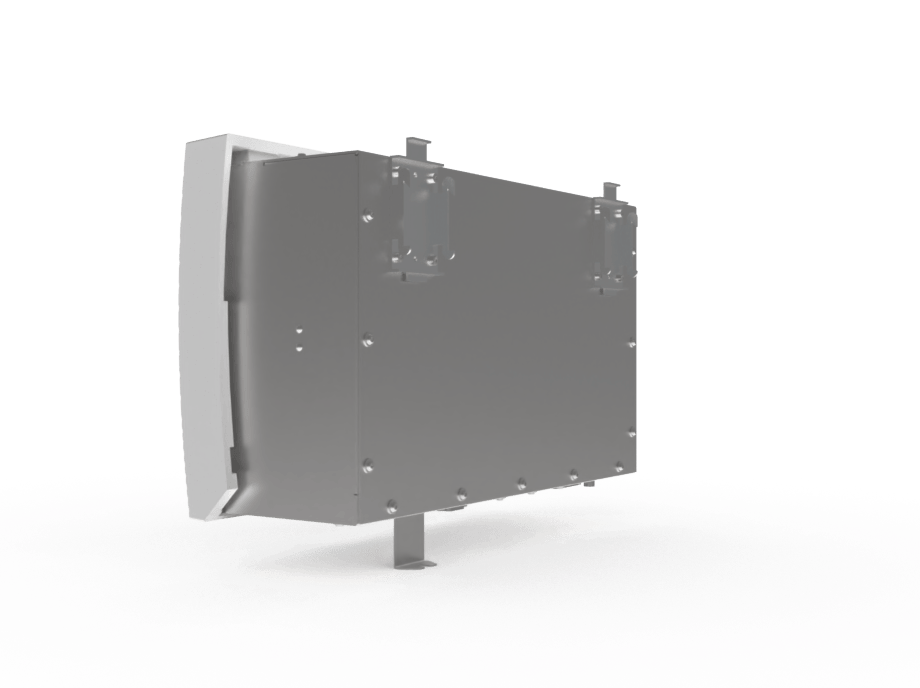

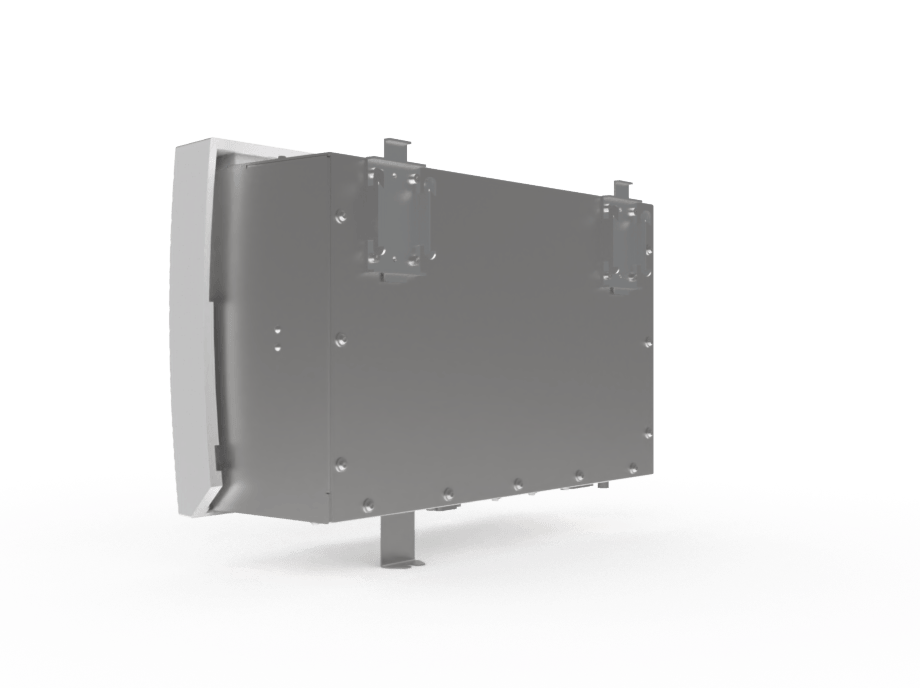

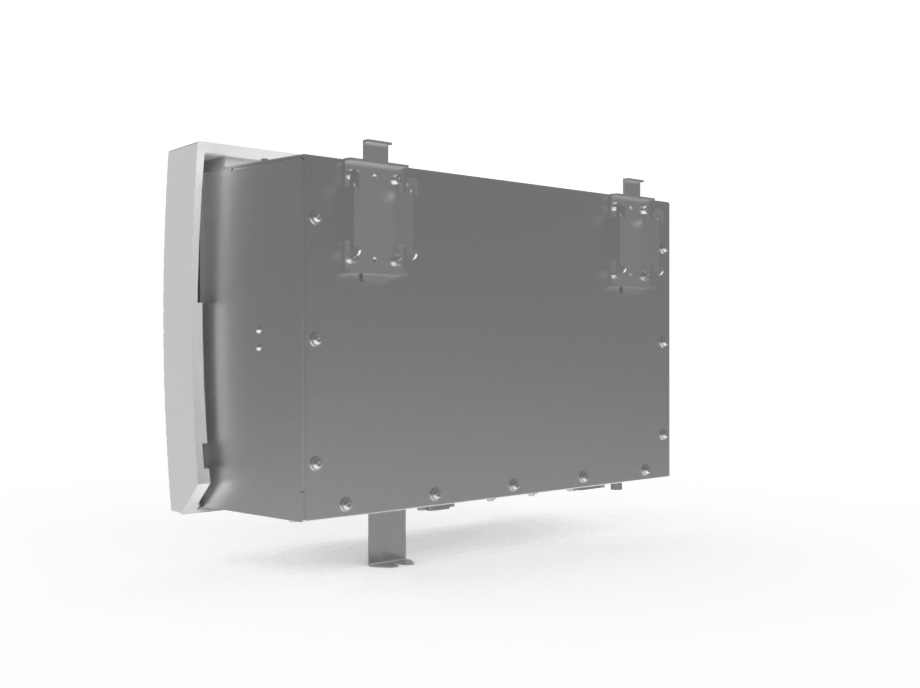

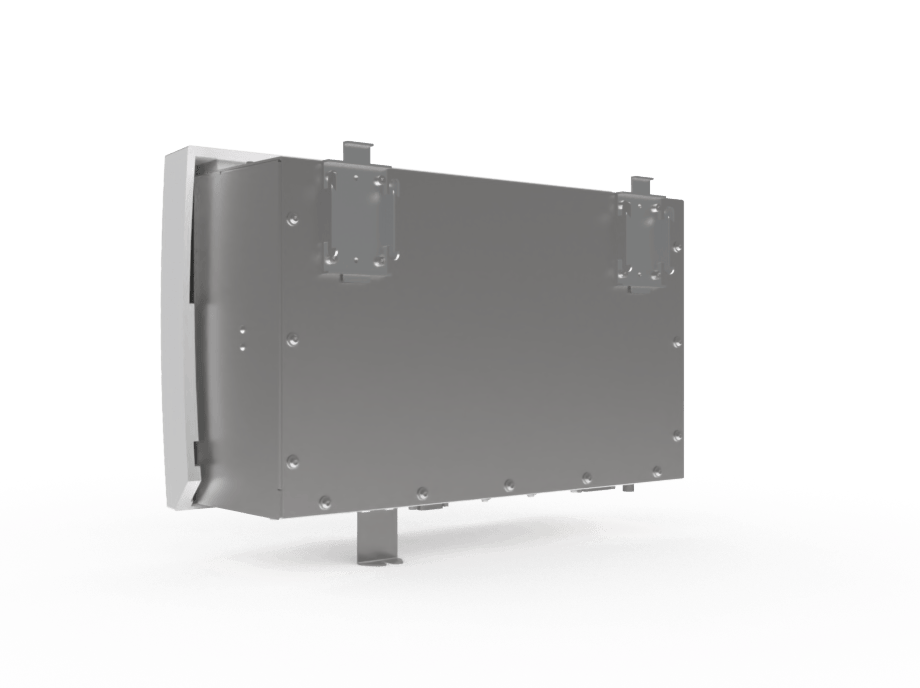

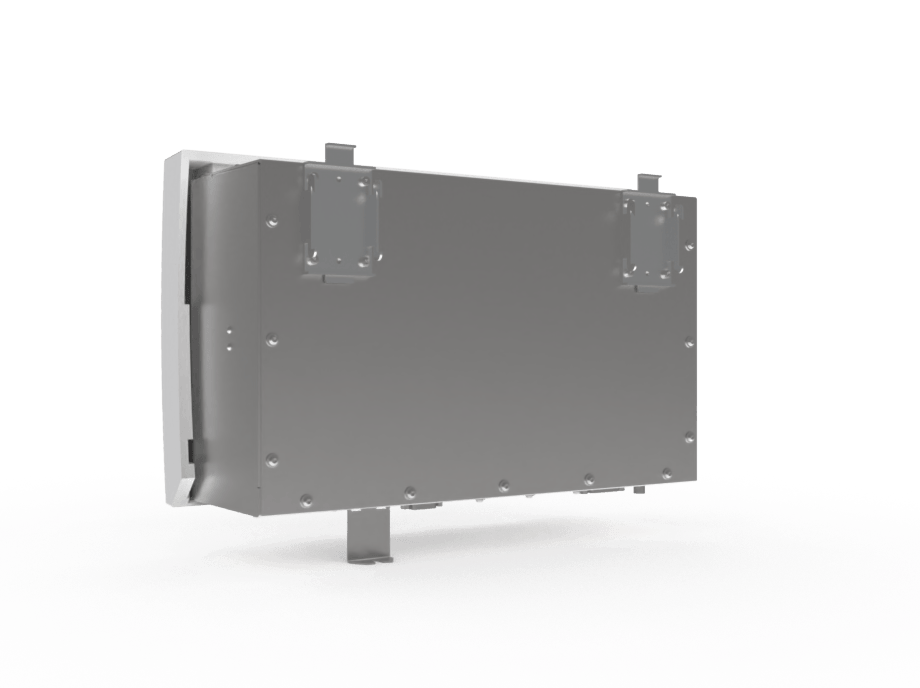

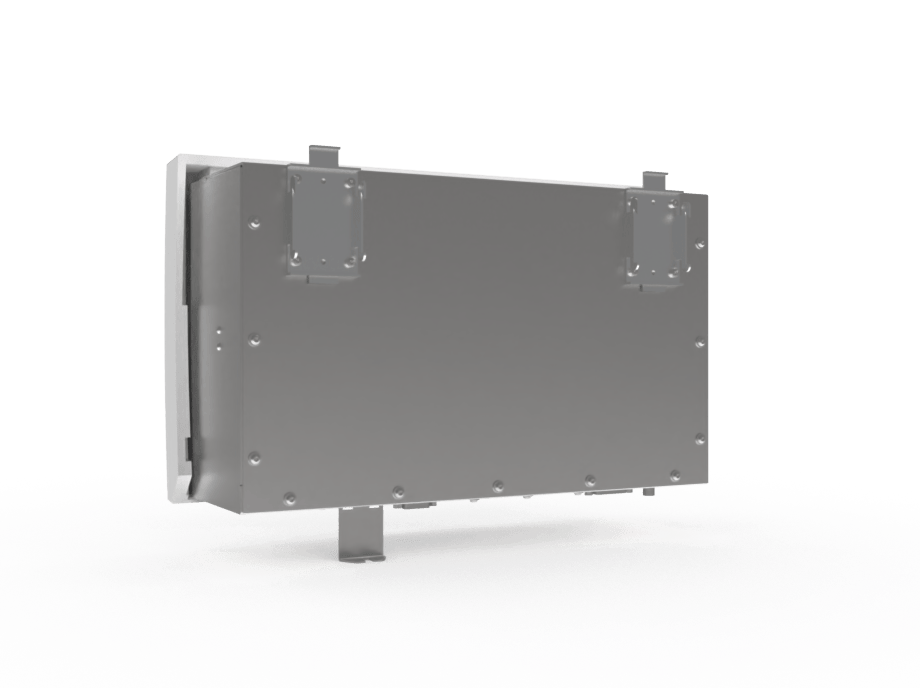

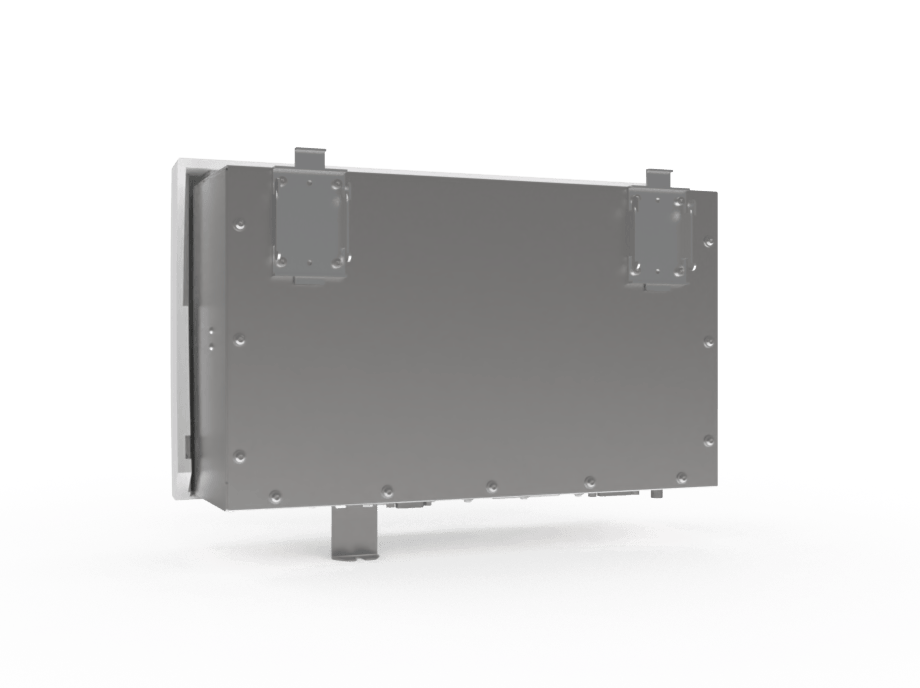

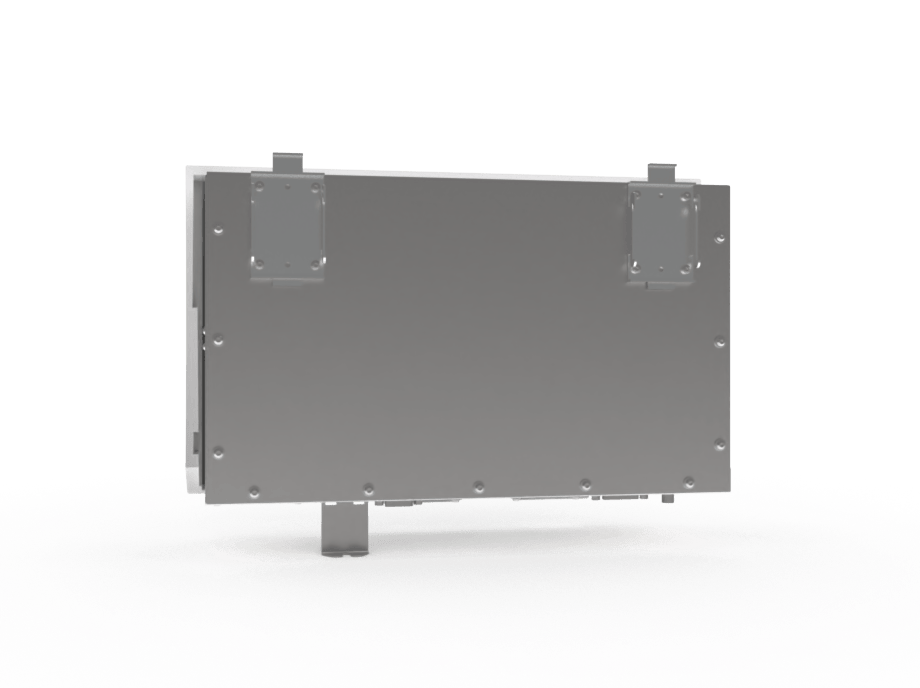

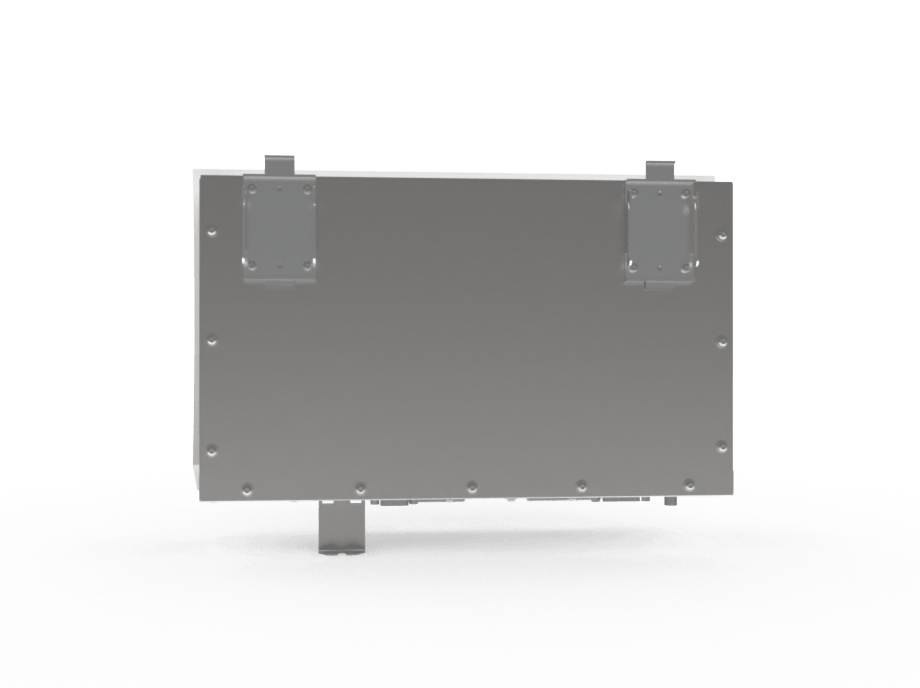

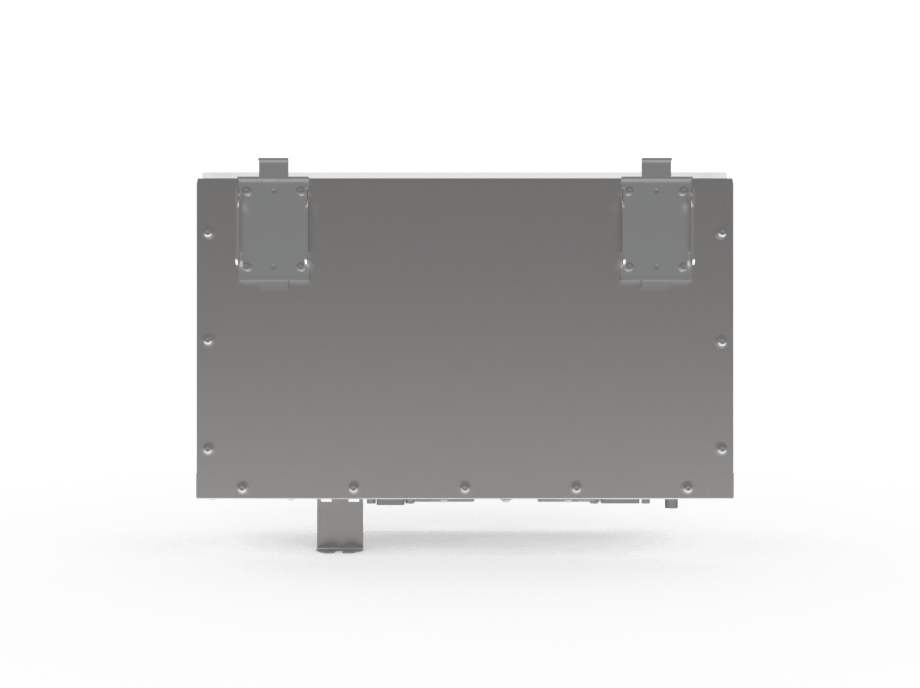

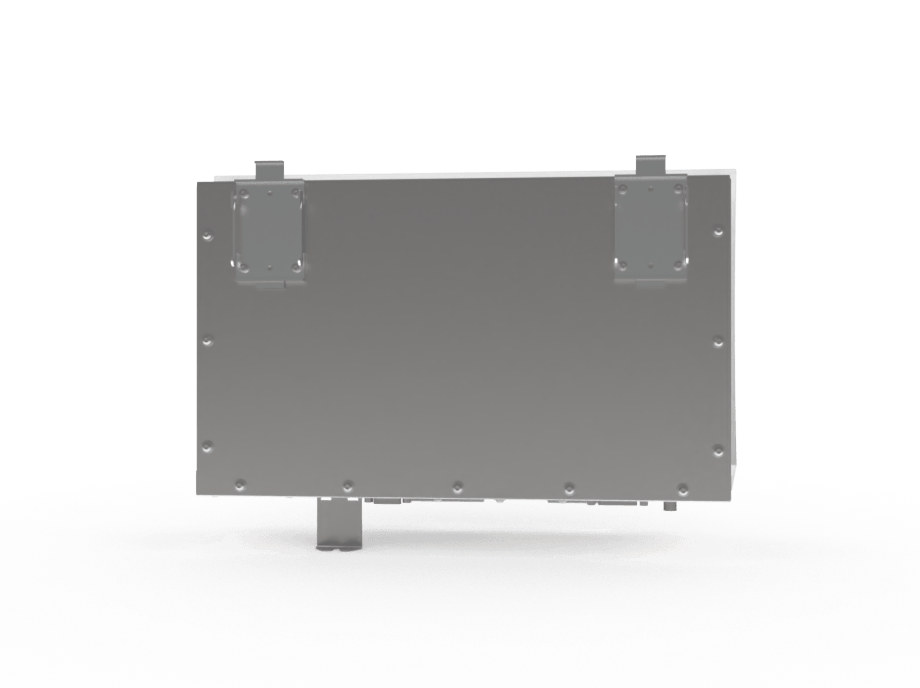

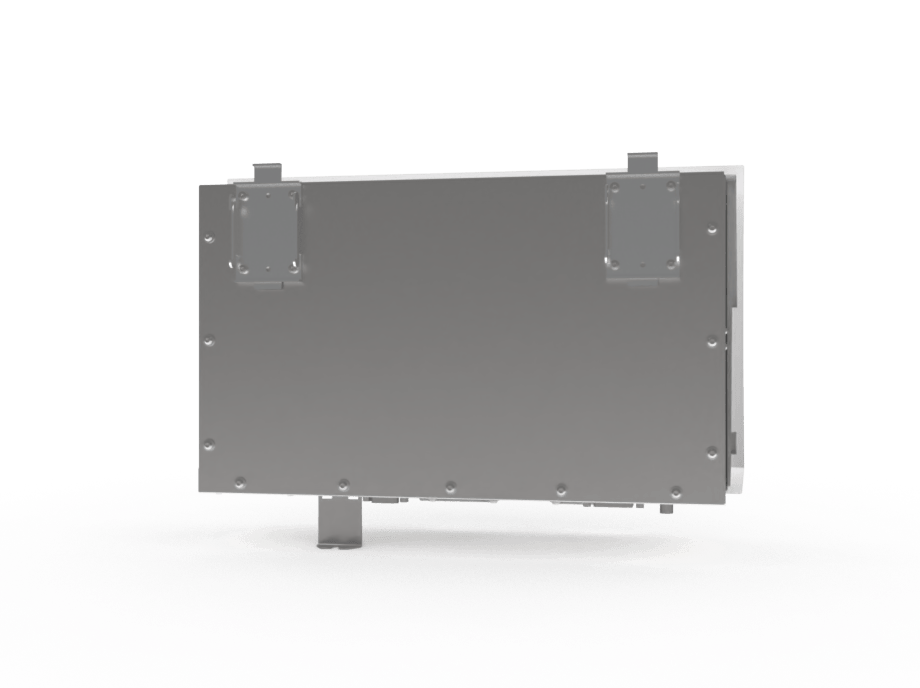

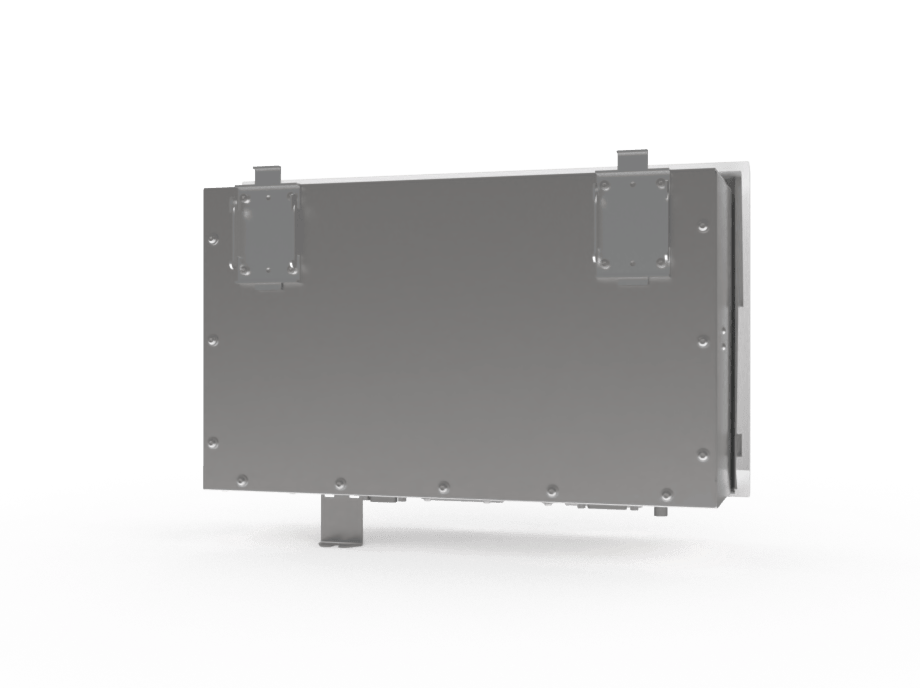

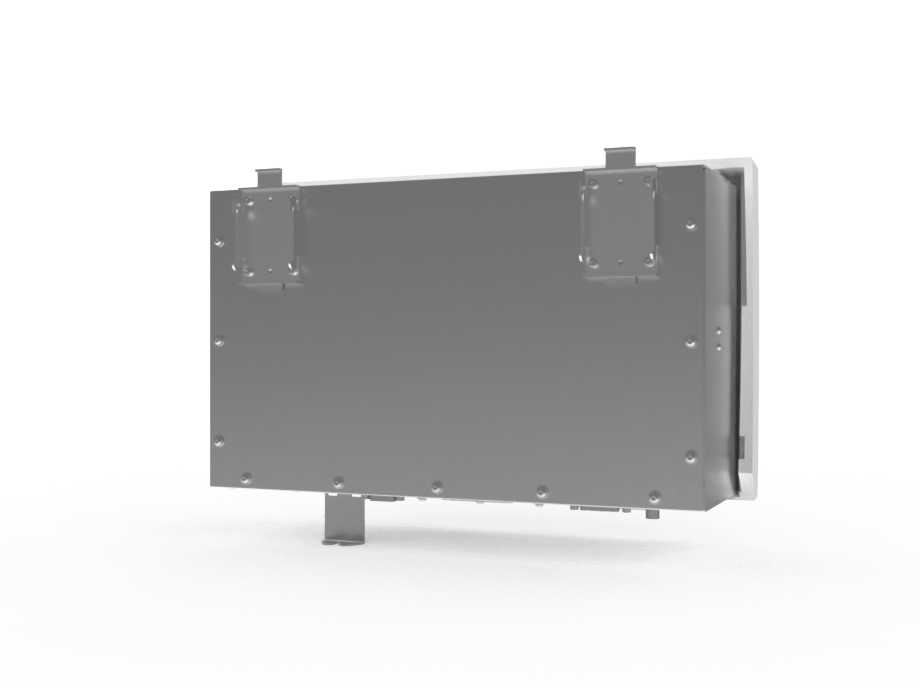

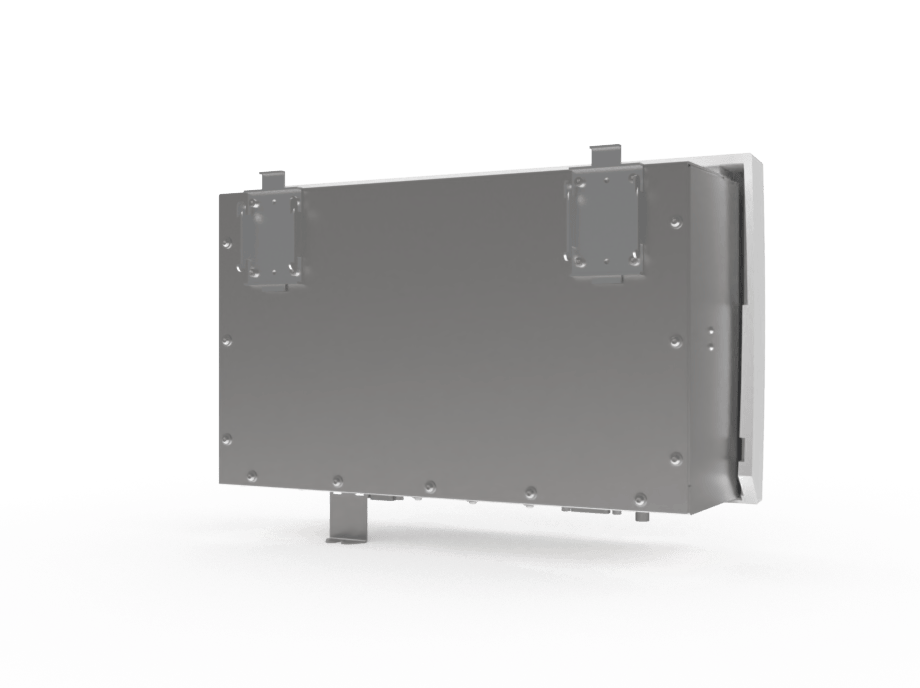

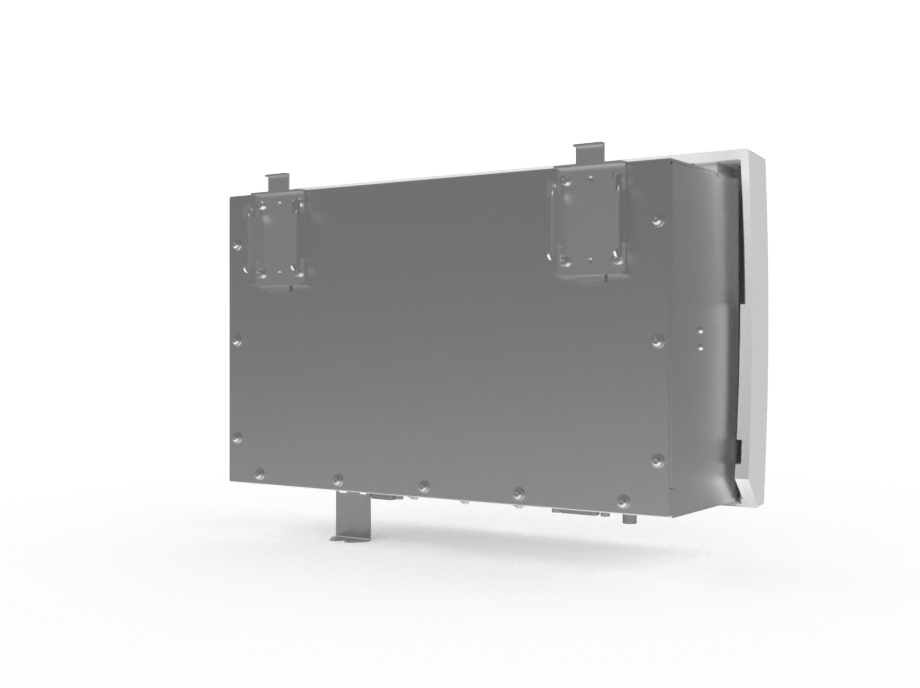

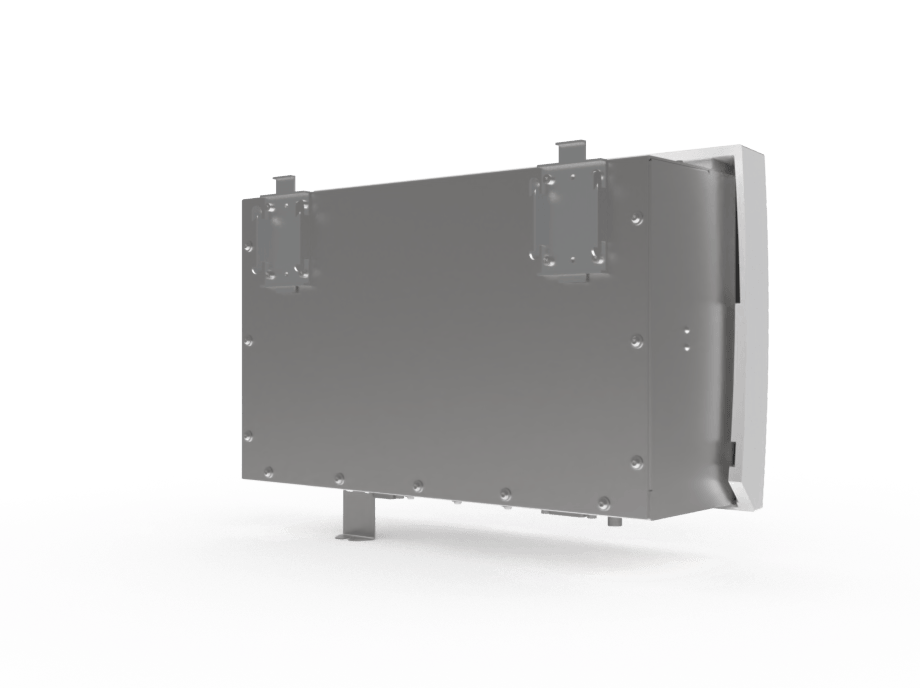

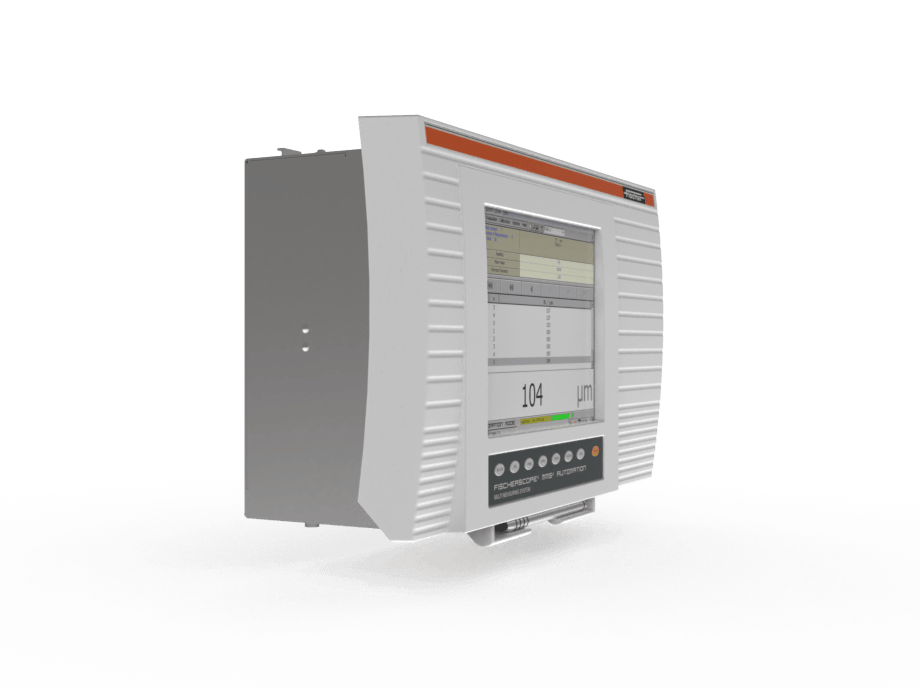

FISCHERSCOPE® MMS® Automation

4 same probes in one application

for automated conductivity measurement

up to 30 m length

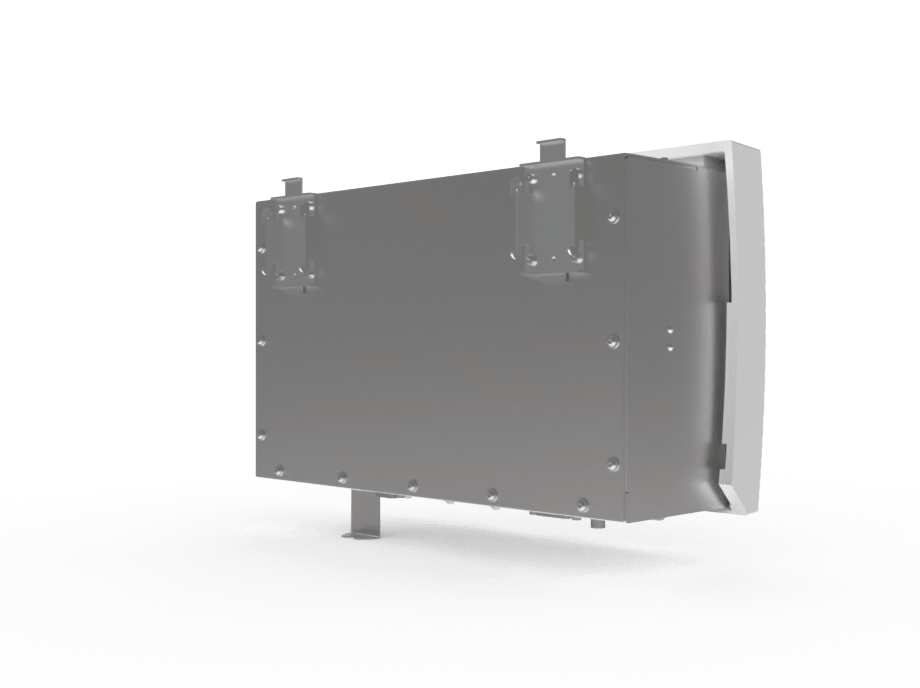

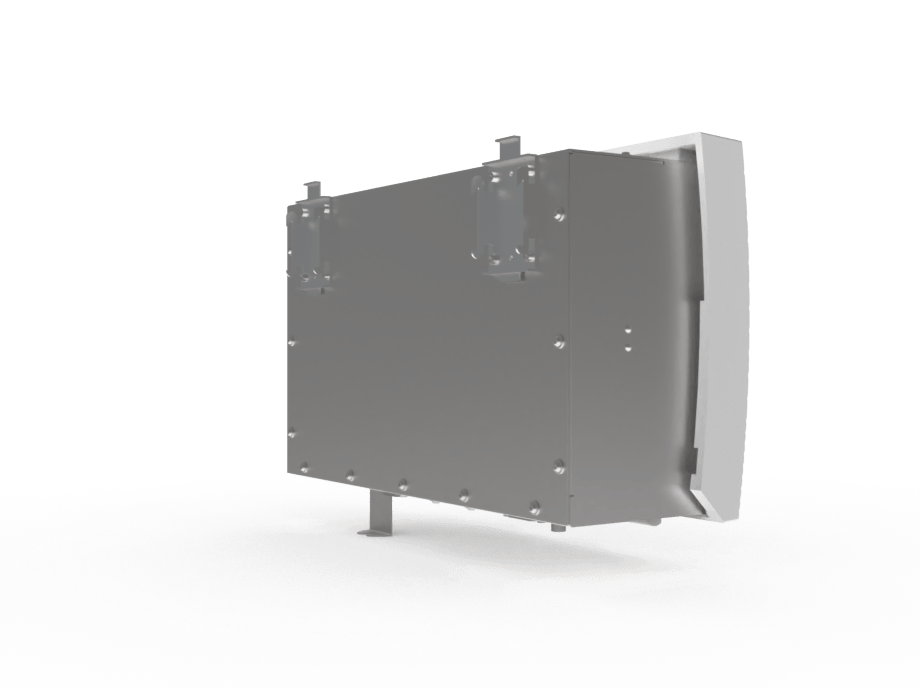

Modular measuring system for coating thickness and conductivity.

Due to its modular design, the FISCHERSCOPE® MMS® Automation is designed for maximum flexibility: It can be equipped with different modules and probes to reliably and precisely solve a variety of measuring tasks with different measuring methods. The in-house developed digital pulse processor DPP+ leads to very high count rates, resulting in shortened measurement times or improved repeatability of your measurement results.

The FISCHERSCOPE® MMS® Automation is available as a pre-engineered solution. Benefit from an existing hardware and software design. Together we modify and adapt the automation device according to your requirements.

Easy integration.

Proven Fischer measurement technology as automated solution

Multi-channel measurement.

Simultaneous measurement with up to four probes of the same type in one application

Measuring over long distances.

Drag chain capable cables up to 30 m length

Well connected.

Standardized PROFINET connection to your PLC

Tailor-made.

Flexible and modularly scalable, a suitable solution for every application

Quickly ready for use.

Thanks to simple top-hat rail mounting

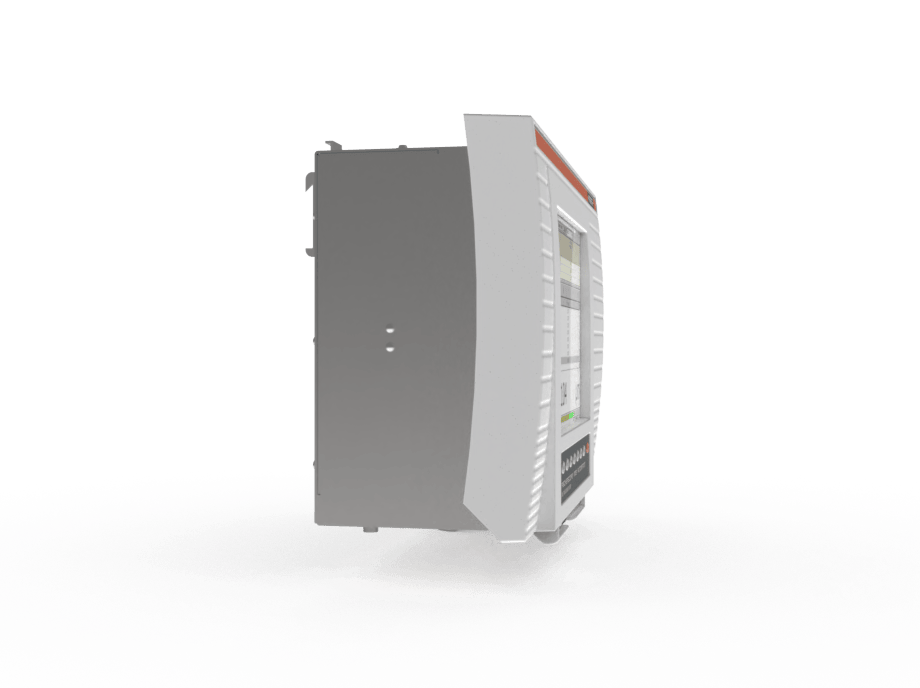

The modular measuring system consists of three parts: The measured values are acquired with probes that are mounted on an automated measuring stand or a robot arm. Via a digitizing unit - the MMS® module - the signals reach the basic unit. The basic unit is mounted in the control cabinet and is responsible for monitoring. It communicates with higher-level units via an RS232 interface.

Due to its modular design, the FISCHERSCOPE® MMS® Automation can be specially adapted to your needs and expanded at any time. For example, you can equip the system with up to four different modules and probes to solve a variety of measuring tasks. Alternatively, up to four identical probes can be used in a single application to achieve a large number of measuring points.

Thanks to standardized interfaces such as ProfiNET and RS232, it can be quickly integrated into quality management systems and automated manufacturing processes. Regardless of whether you want to inspect with just one probe on the head of an industrial robot or work with up to four probes in parallel in a measuring station directly in your production line.

Features

Measuring method: Magnetic inductive, amplitude sensitive and phase sensitive eddy current, microresistivity.

Measured value memory: 1,000,000 in 1,000 applications

Various interfaces for process control

Available modules: PERMASCOPE®, PHASCOPE® DUPLEX, SIGMASCOPE®, SR-SCOPE®, NICKELSCOPE®

Multi-channel measurement of up to four identical probes

Remote controllable by PLC control

Measuring range: Depends on the combination of coating and base material and the probe used

Probes available for various applications

Application examples

- Metallic coatings on electrically non-conductive materials

- Duplex coatings

- Electroplating of nickel layers on non-ferrous metals and insulating base materials

- Electrical conductivity of non-ferrous metals

- Copper thickness on PCBs

- And much more

Coating thickness measurement of almost all coating materials on metals

Do you have further applications? Then contact us!

Modules

Coating thickness measurement with magnetic inductive and eddy current methods.

Typical applications:

- Electrically insulating coatings on various metals, such as paint on steel or aluminum

- Electrically conductive, non-magnetizable coatings on ferrous metals, e.g. zinc, copper or chromium on steel

- Weakly electrically conductive coatings on highly conductive metals, such as chromium and electroless nickel on copper or aluminum

Measuring of duplex coatings with magnetic inductive measuring method as well as amplitude sensitive and phase sensitive eddy current method.

Typical applications:

- Paint on steel and aluminum

- Paint and zinc coatings, such as thin EPD coatings on steel; both layers are measured in one step

- Brake line hoses

- Wire (mesh and grid), such as for shopping carts

Coating thickness measurement with electrical conductivity.

Typical applications:

- Measuring copper layers on PCBs

- Testing of aluminum alloys in incoming goods

Coating thickness measurement with micro resistance method.

Application:

- Thickness of individual copper layers on multilayer PCBs

Coating thickness measurement with magnetic measuring methods.

Typical applications:

- Electroplating nickel coatings on non-ferrous metals and insulating base materials

- Non-magnetic coatings such as copper, aluminum or lead on steel or iron

PERMASCOPE®

- Electrically insulating coatings on various metals, such as paint on steel or aluminum

- Electrically conductive, non-magnetizable coatings on ferrous metals, e.g. zinc, copper or chromium on steel

- Weakly electrically conductive coatings on highly conductive metals, such as chromium and electroless nickel on copper or aluminum

Coating thickness measurement with magnetic inductive and eddy current methods.

Typical applications:

PHASCOPE® DUPLEX

- Paint on steel and aluminum

- Paint and zinc coatings, such as thin EPD coatings on steel; both layers are measured in one step

- Brake line hoses

- Wire (mesh and grid), such as for shopping carts

Measuring of duplex coatings with magnetic inductive measuring method as well as amplitude sensitive and phase sensitive eddy current method.

Typical applications:

SIGMASCOPE®

- Measuring copper layers on PCBs

- Testing of aluminum alloys in incoming goods

Coating thickness measurement with electrical conductivity.

Typical applications:

SR-SCOPE®

- Thickness of individual copper layers on multilayer PCBs

Coating thickness measurement with micro resistance method.

Application:

NICKELSCOPE®

- Electroplating nickel coatings on non-ferrous metals and insulating base materials

- Non-magnetic coatings such as copper, aluminum or lead on steel or iron

Coating thickness measurement with magnetic measuring methods.

Typical applications: