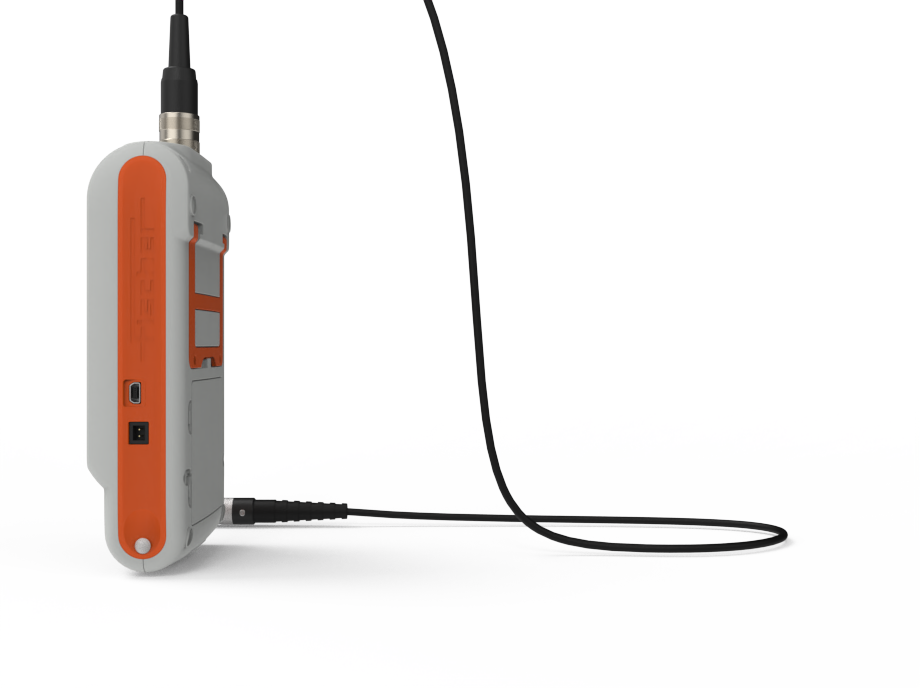

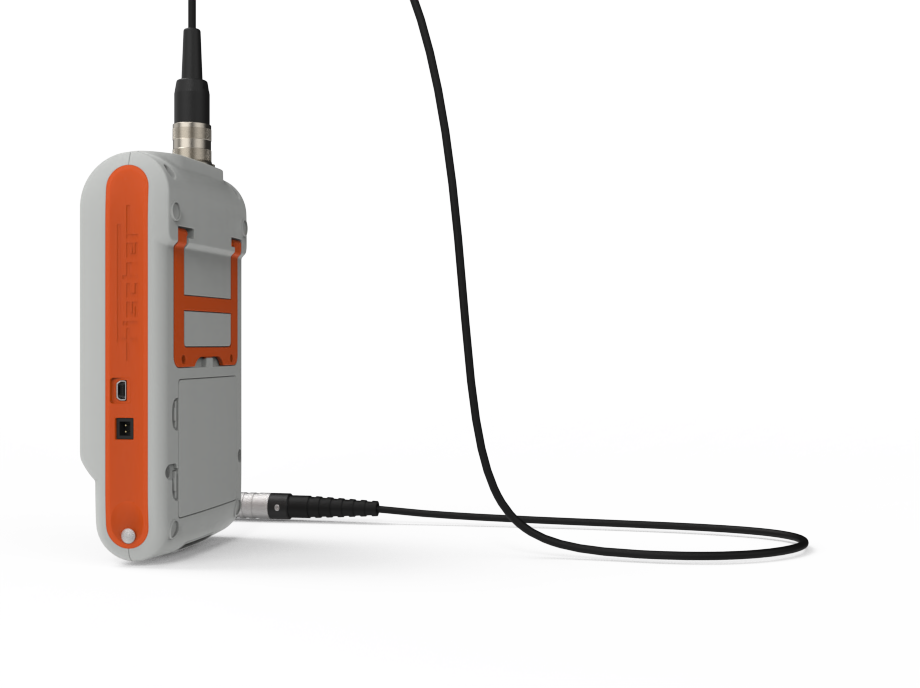

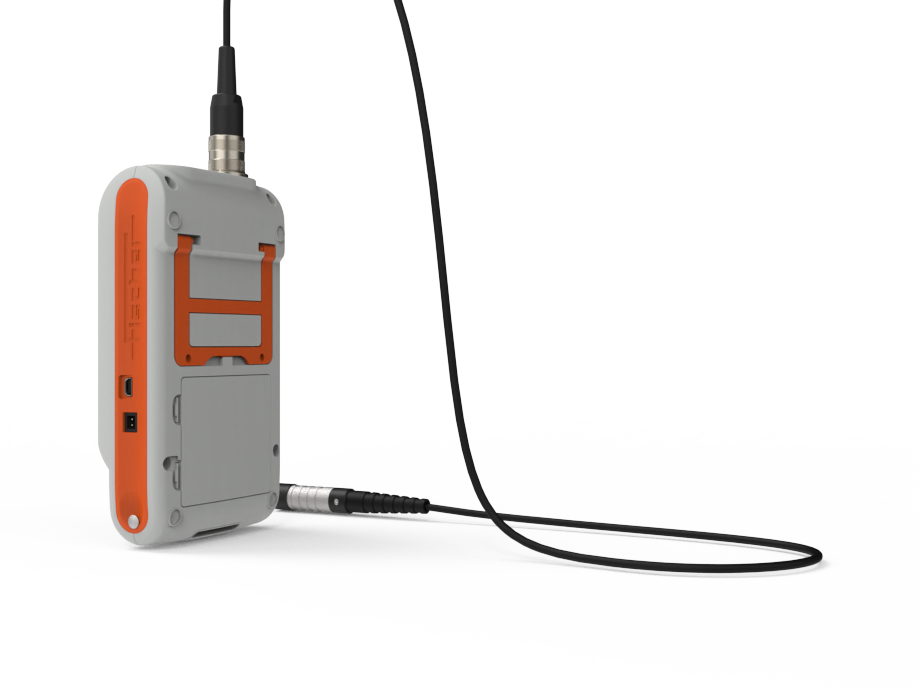

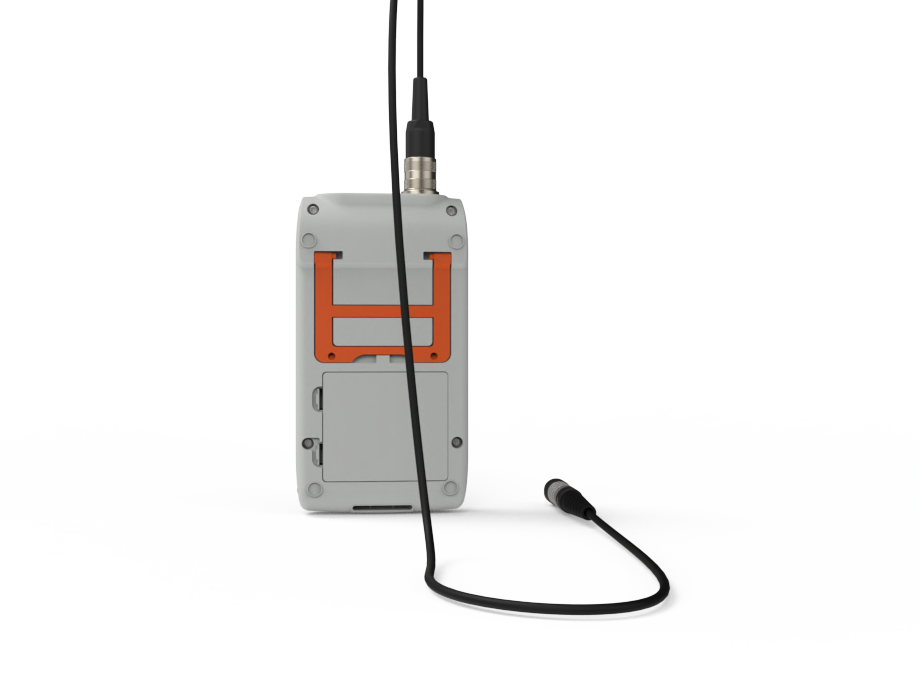

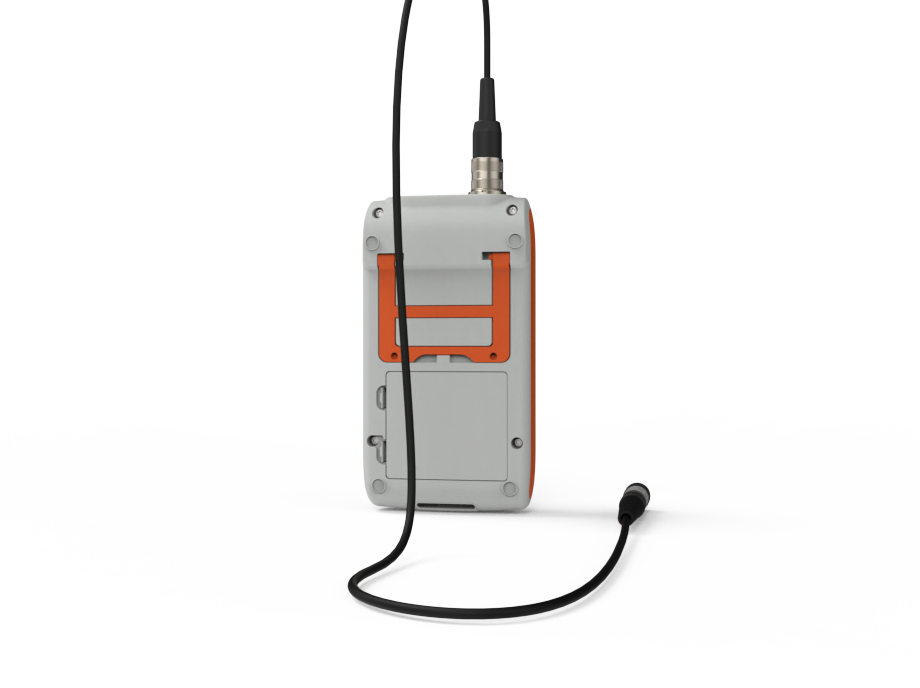

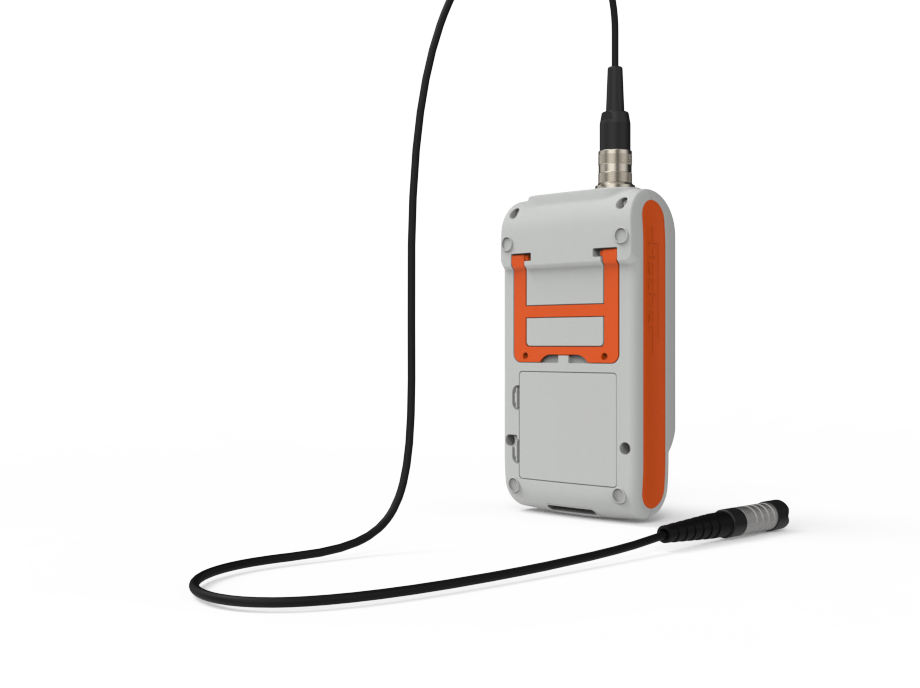

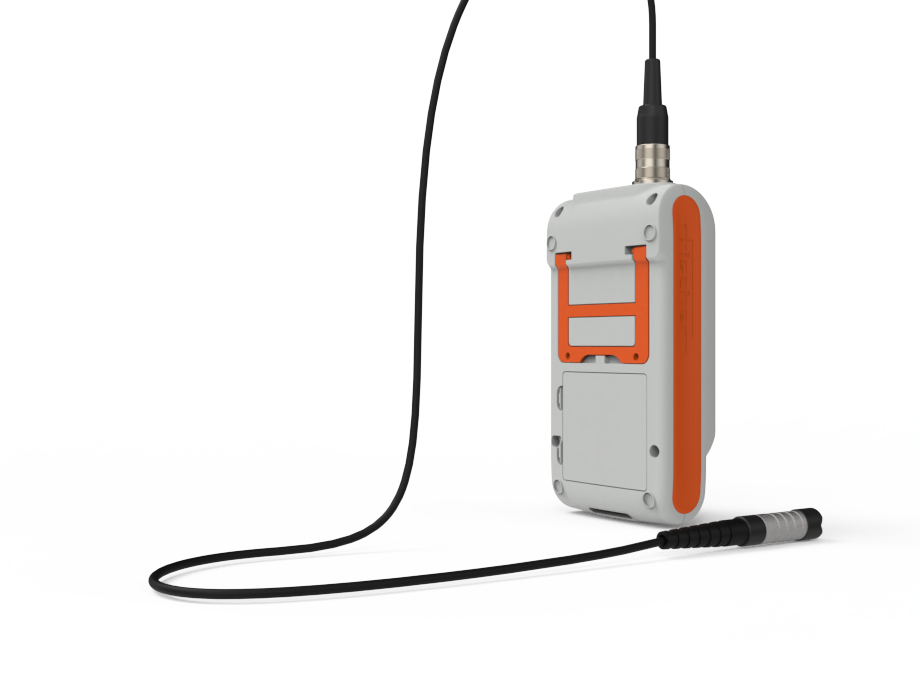

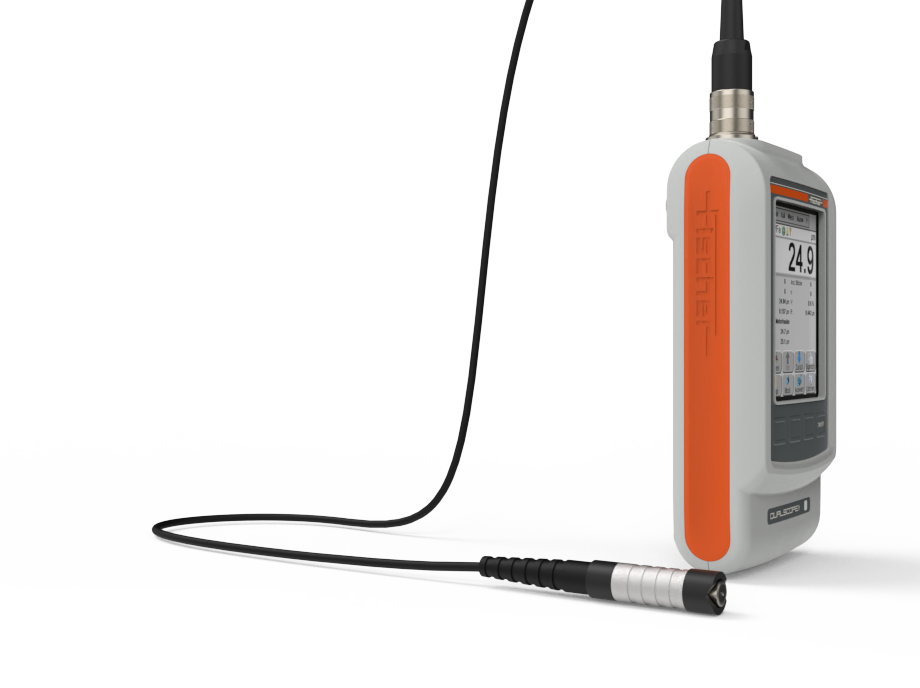

DUALSCOPE® FMP100 and H FMP150

reduction of user errors

on curved and rough surfaces

and save time

Coating thickness measurement for professional quality assurance.

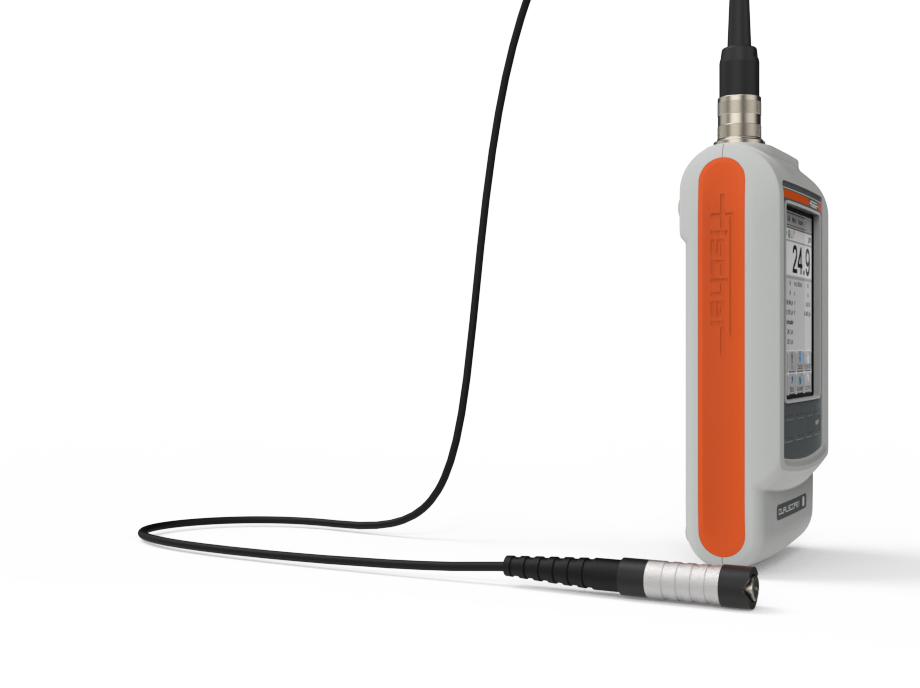

The powerful DUALSCOPE® FMP100 and DUALSCOPE® H FMP150 coating thickness gauges are predestined for the most demanding measuring tasks in quality assurance. The former combines the magnetic inductive measuring method and the eddy current method in one device. This allows you to measure coating thicknesses on steel and coating thicknesses on non-ferrous metals without changing the measuring device. The DUALSCOPE® H FMP150 also offers you the magnetic method.

Two in one.

Magnetic induction and eddy current method for highest flexibility (FMP100)

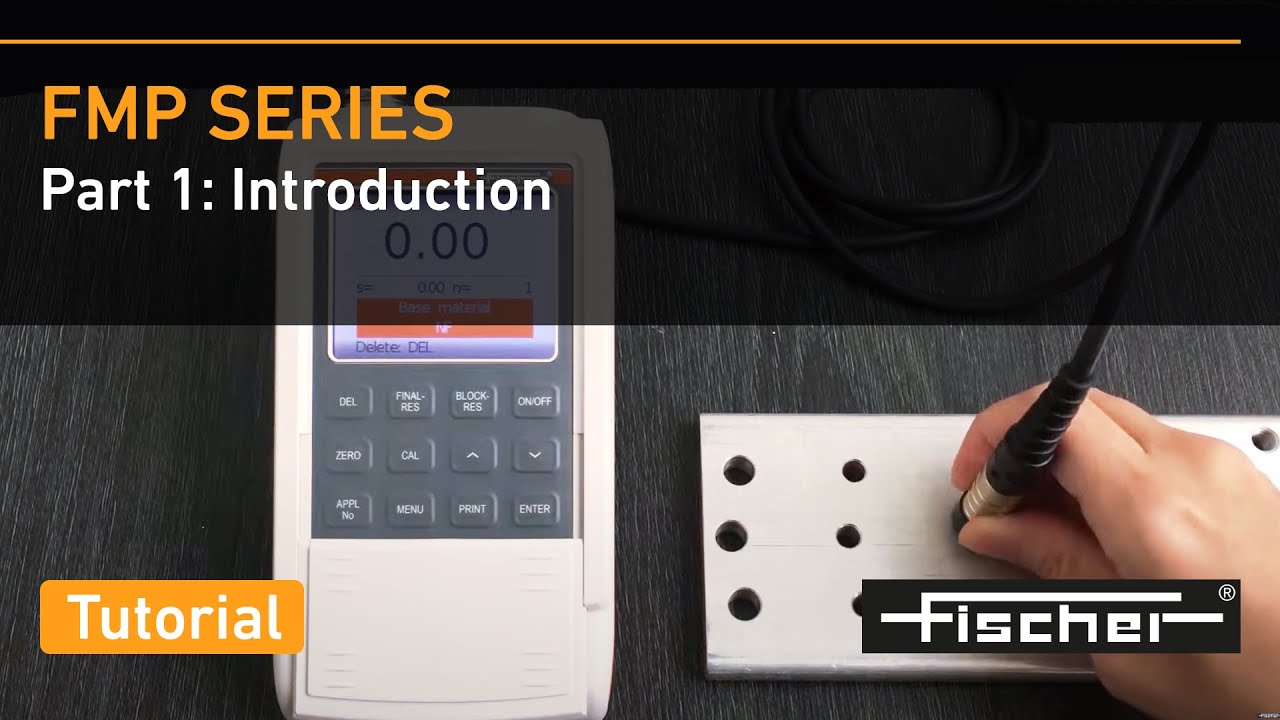

Inspection plans.

Step-by-step measurement guide to reduce user errors

Meeting all challenges.

Reliable and fast results for ambitious measurement tasks

Three in one.

Magnetic induction, magnetic and eddy current method for highest flexibility (FMP150)

Maximum flexibility.

Choose the right probe for your application

Easy to use.

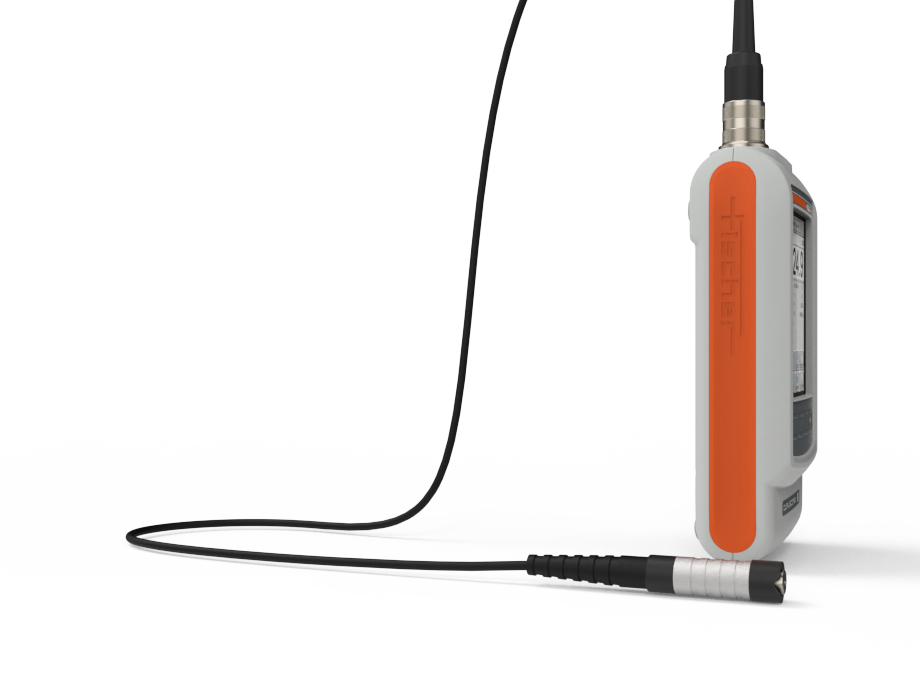

Fast and simple operation thanks to intuitive menu

Features

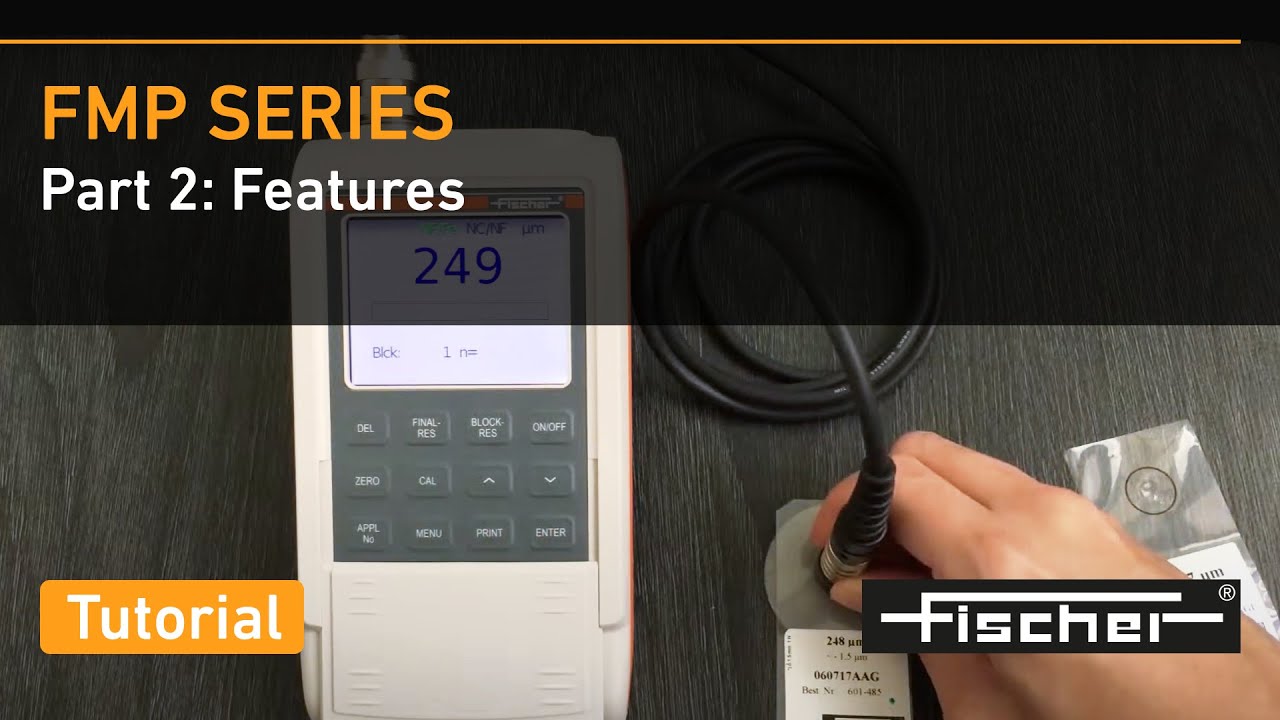

Automatic probe and base material detection

Measuring method: Magnetic induction method, eddy current method and magnetic method, depending on the device

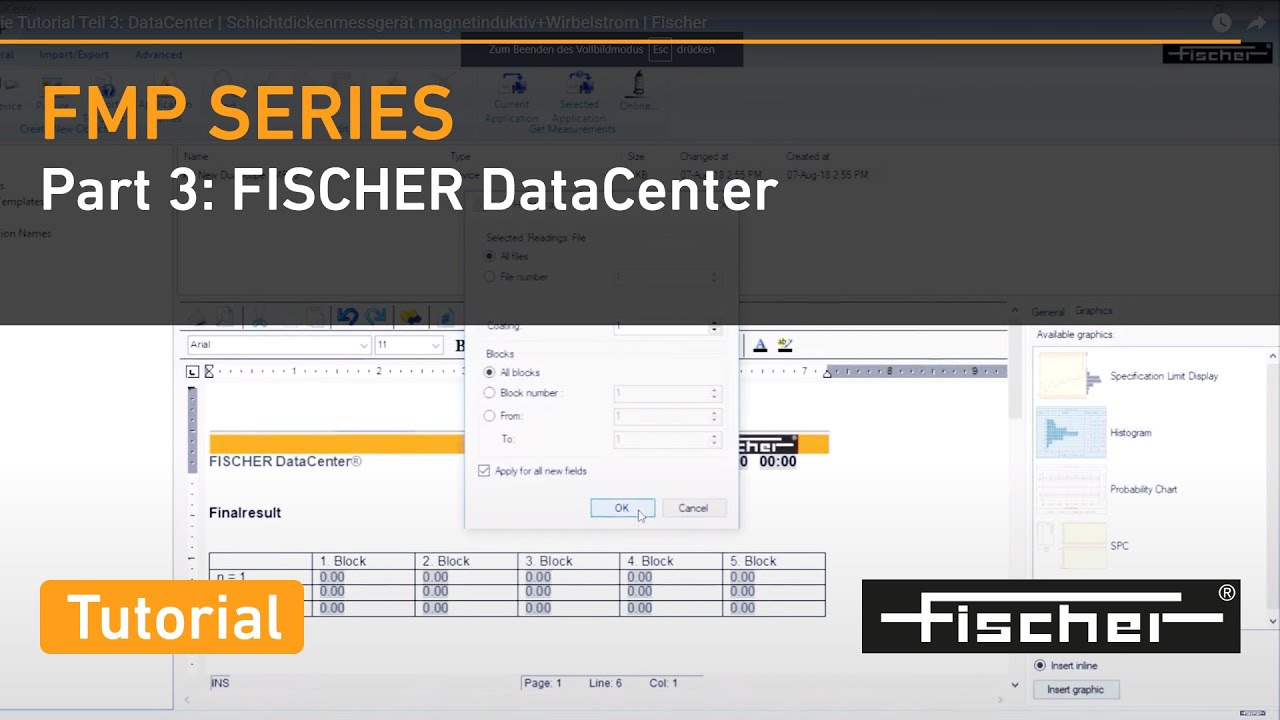

Simple data transfer via USB

Measured value memory: For a large number of measurements

Optionally available: Create individual test plans with additional, fee-based software license

High-resolution touchscreen display with virtual keyboard, operable with pen or finger

Limit value monitoring via sound

Measuring range: Dependent on coating-base material combination and probe used

Probes available for a wide range of applications

Application examples

- Non-magnetic coatings on iron and steel

- Insulating layers on non-ferrous metals

- Duplex coatings (paint/fire zinc) on steel in the area of heavy corrosion protection, whereby the paint and zinc coatings are measured in one measurement process and displayed separately

- Thick metal and protective coatings on steel or iron (DUALSCOPE® H FMP150)

- Nickel layers on non-ferrous metals or electrical insulators (DUALSCOPE® H FMP150)

Do you have other applications? Then contact us!

Application Notes

AN007 Thickness measurement of conformal coatings on printed circuit boards 0.99 MB AN011 Measuring protective coatings in accordance with SSPC-PA2 0.35 MB AN012 Coating thickness measurements on coated aluminium blinds 0.52 MB AN014 Non-destructive measurement of CDP coatings inside hollow car body parts 0.53 MB AN020 Measurement of SAM (sprayable acoustic material) coatings for the automotive industry 0.47 MB AN031 Measurement of thick coatings on pipelines 0.62 MB AN035 Quality control of paint coatings on car bodies using individually created inspection plans 0.77 MB AN046 Measurement of thick NiP coatings on automotive parts 0.78 MB AN062 Measuring electroplated parts with user-defined inspection plans 0.73 MB AN075 Measuring anti-fouling coatings on marine structures 1.05 MB AN077 Measuring the thickness of micaceous iron oxide coatings 1.03 MB AN091 Different ways to achieve valid measurement values and optimize measurement performance 0.20 MBTutorials

Webinars

Brochures