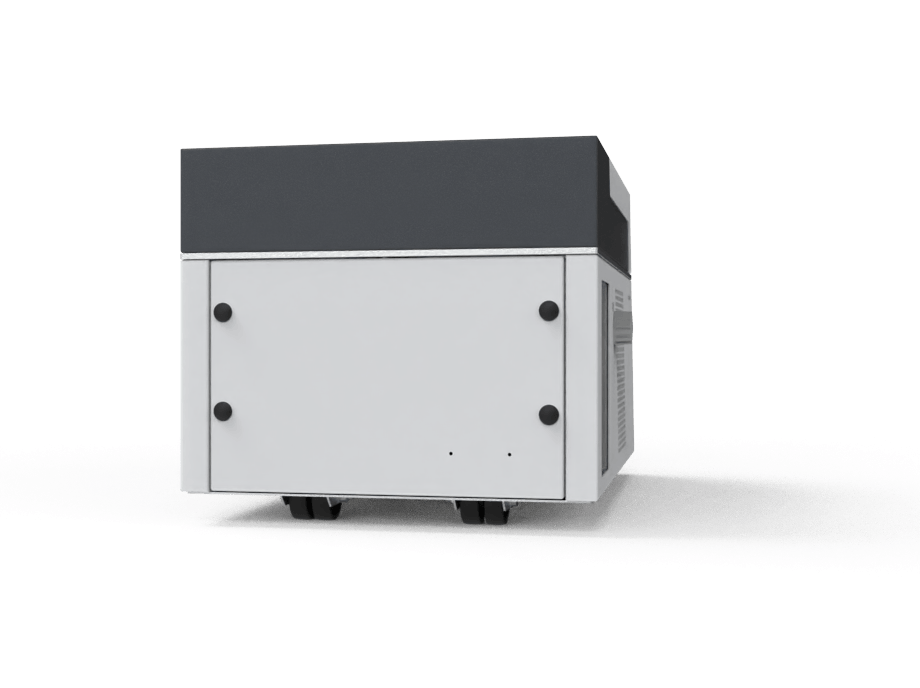

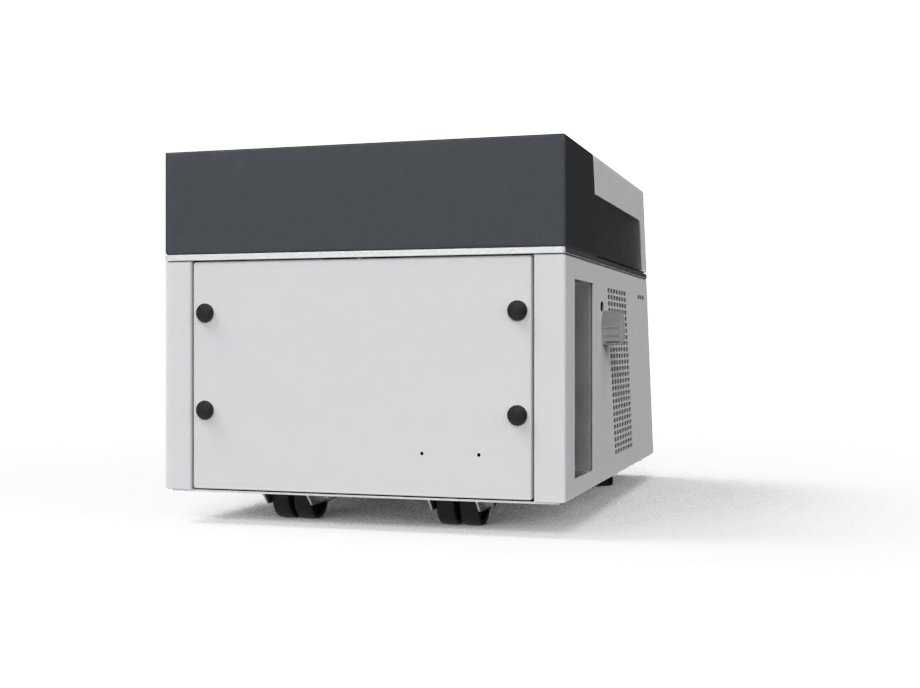

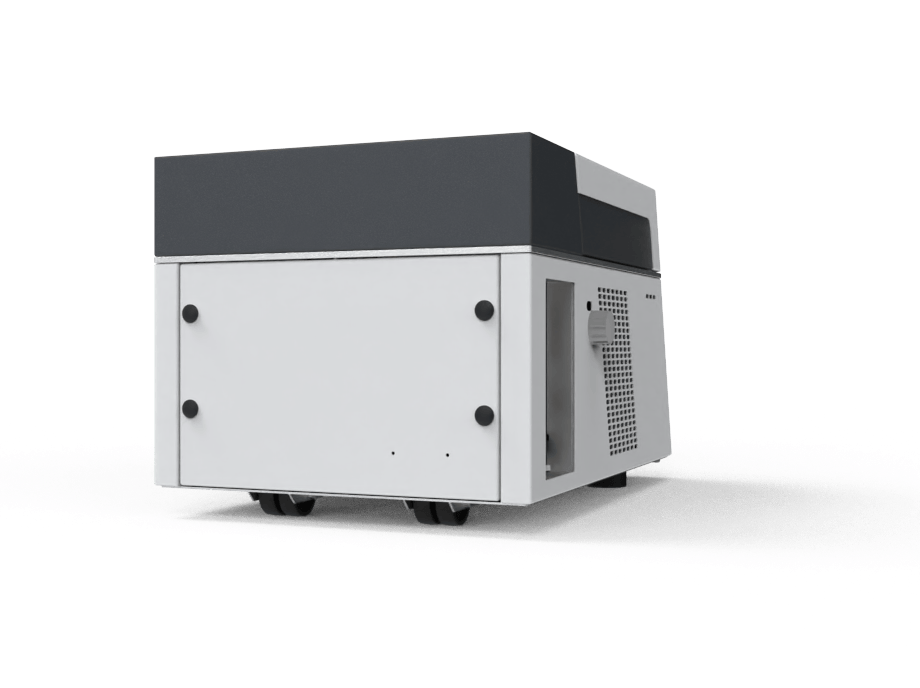

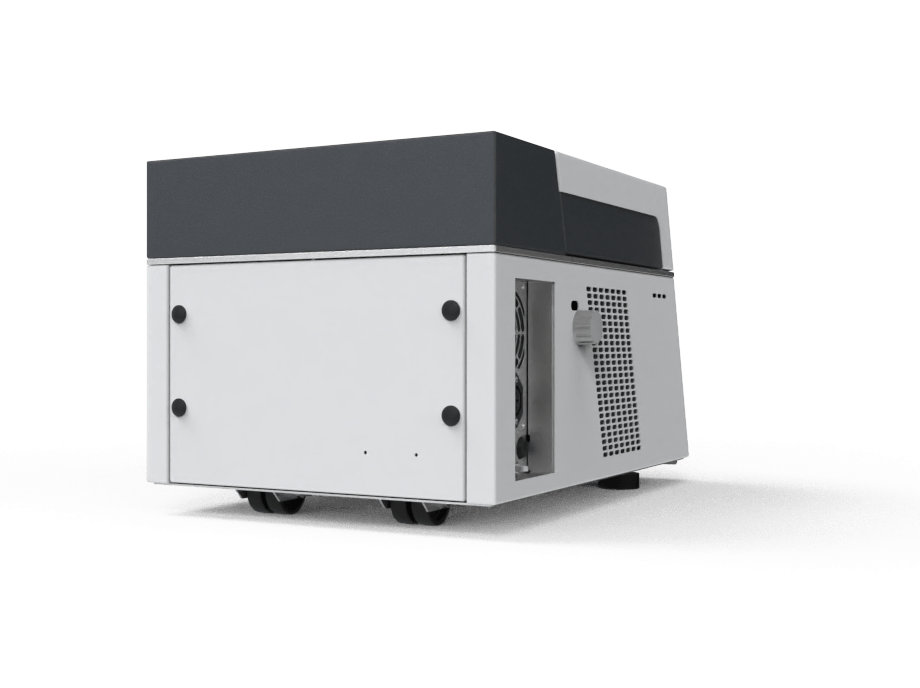

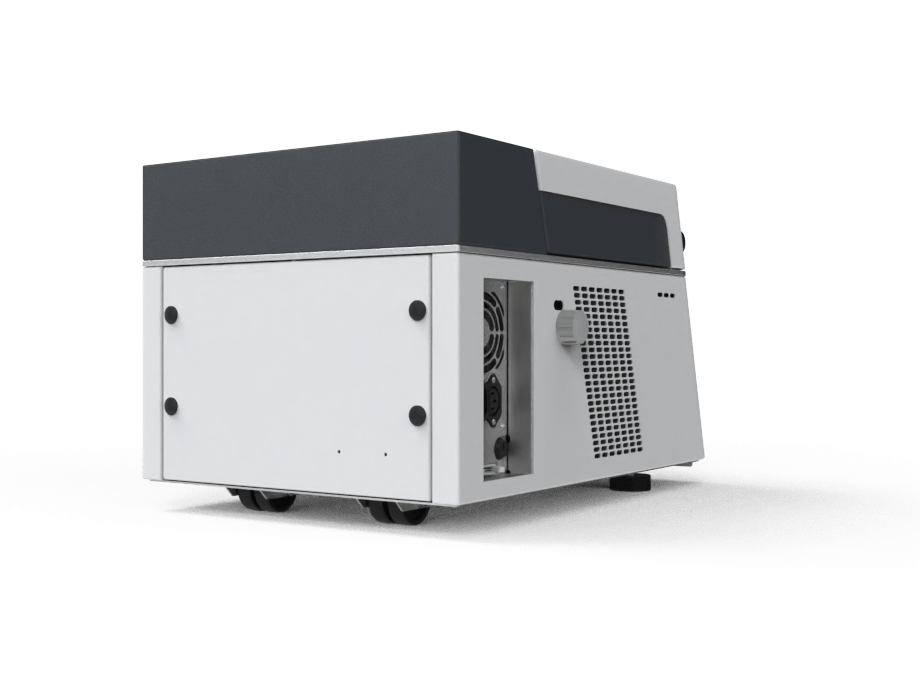

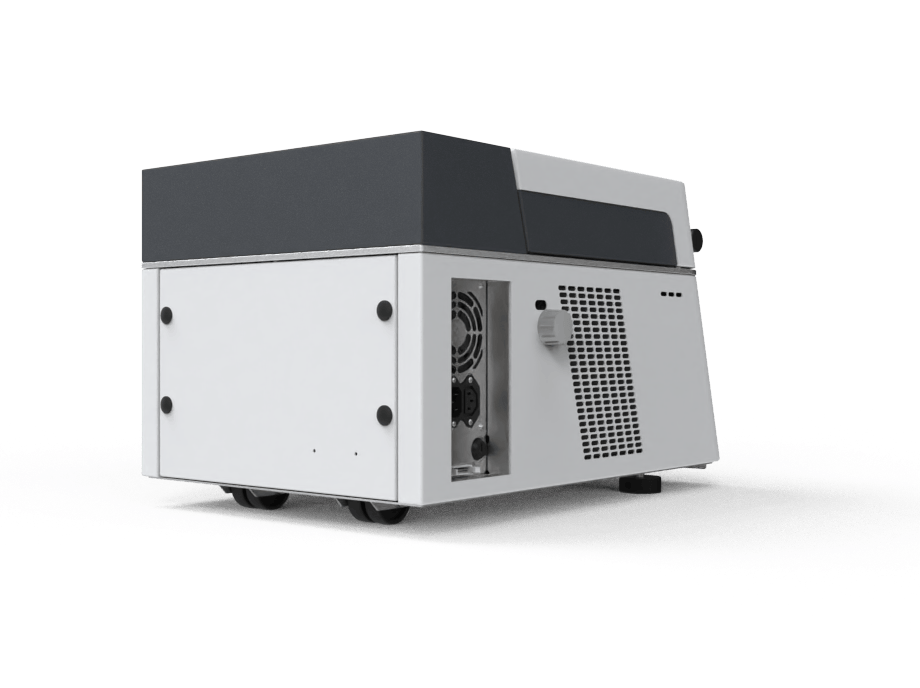

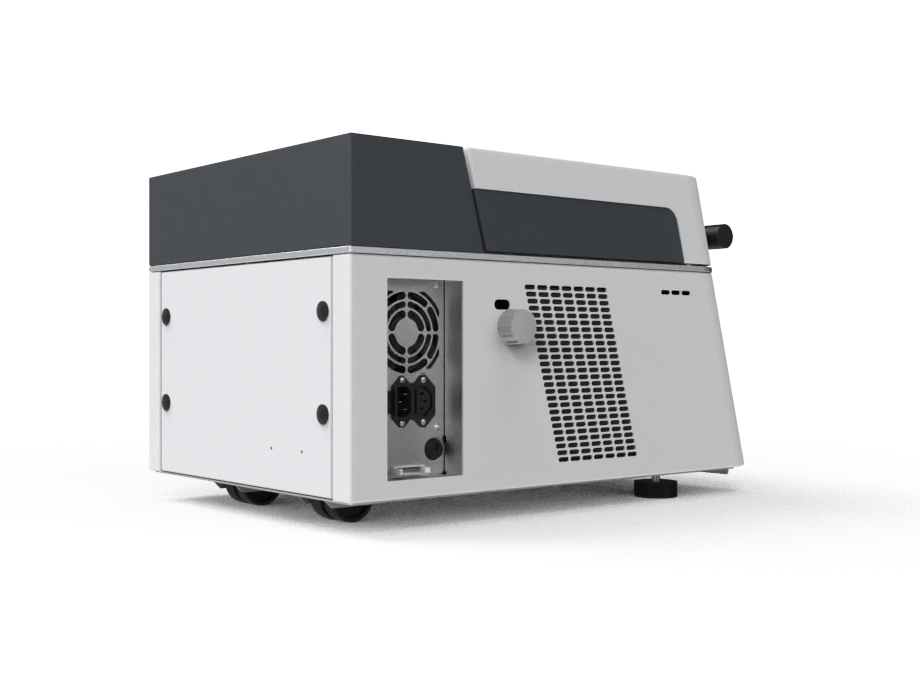

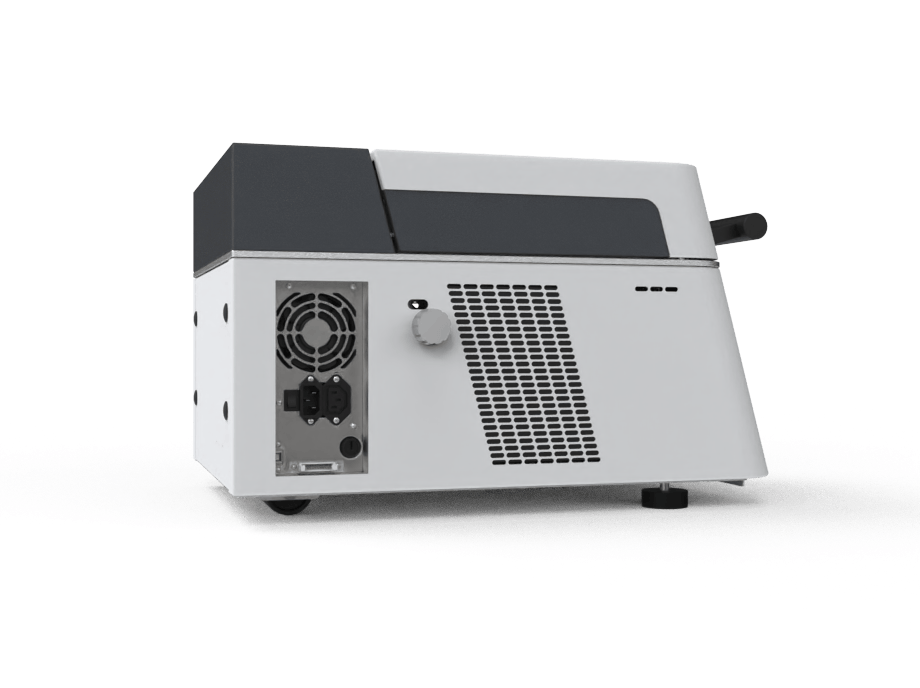

GOLDSCOPE SD®

standard measuring tasks

and high resolution

full protection device

Cost-effective X-ray fluorescence analysis around gold and precious metals.

Not everything that glitters is gold: With the help of the GOLDSCOPE SD® you can check the authenticity of jewelry and analyze the composition of gold and precious metals quickly and non-destructively. The GOLDSCOPE SD® family includes various devices to cover specific requirements from the quick purchase and sale of gold to the high-precision analysis of precious metals. Different detectors as well as various space-saving housing types allow the use suiting your measuring task and location.

Your safety.

Best measuring performance for your precious metal alloys

Quick-measure design.

The sample is placed and ready for measurement in just a few steps

Versatile.

Ideal for pawnshops, gold trading, test laboratories and jewelry manufacturers

Commissioning.

Extremely fast and easy, measuring tasks are already pre-programmed

Balanced.

Optimal cost-benefit ratio

DPP+ digital pulse processor.

Shorter measuring times or improvement of standard deviation*

*compared to the DPP

Features

Higher count rates and significantly reduced measurement times thanks to DPP+

Silicon PIN and silicon drift detectors provide very good detection accuracy and high resolution

Larger hood: From 90 up to 130 mm possible height of samples, depending on device

Apertures: fixed or 4-fold changeable*

Primary filters: fixed or 6-fold changeable*

*depending on deviceMeasuring spot approx.: Ø 0.3 mm or Ø 0.7 mm, depending on device

Type approved full protection device

Application examples

- Composition of precious metal alloys

- Authenticity check of gold jewelry, watches and coins

- Analysis of dental alloys

- Rhodium layer on gold alloy and gold layer on silver alloy

Do you have further applications? Then contact us!