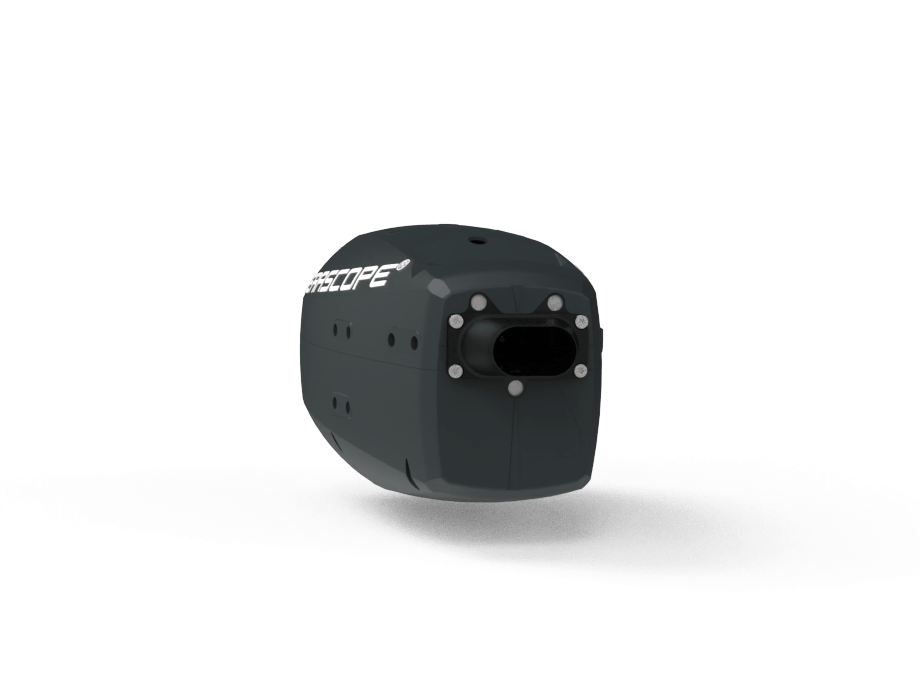

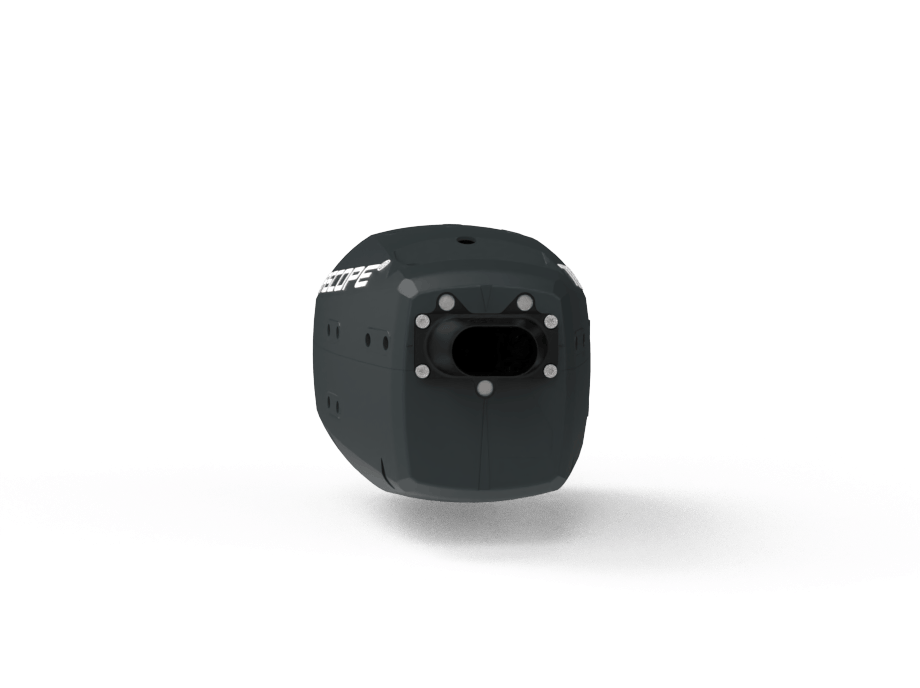

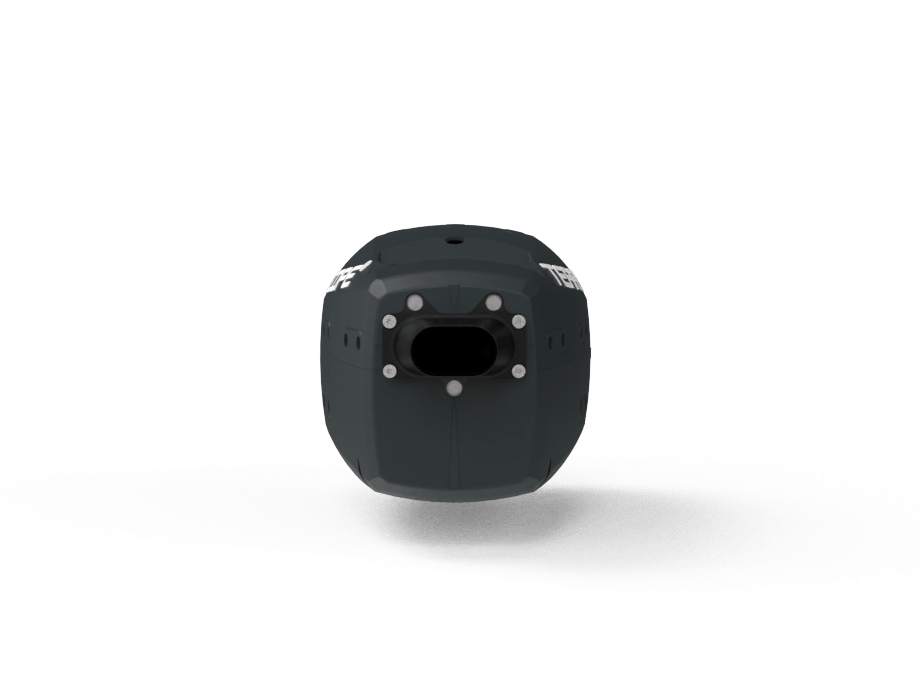

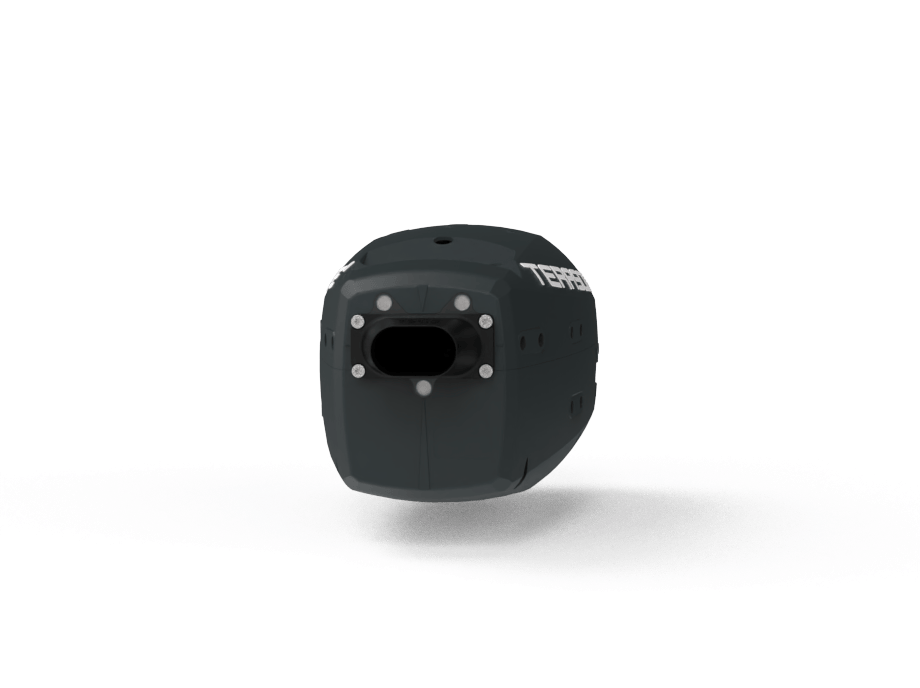

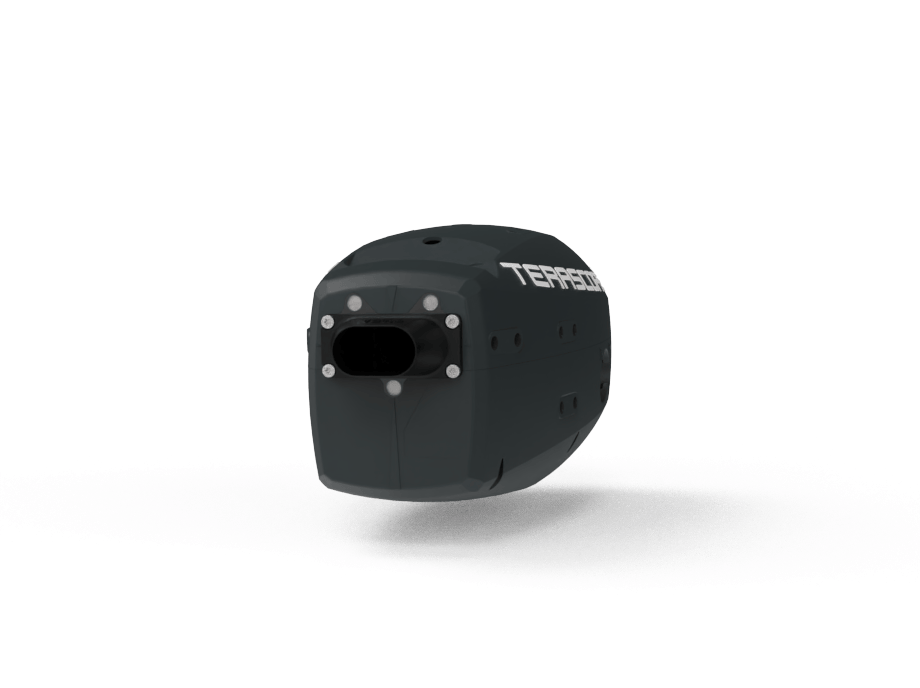

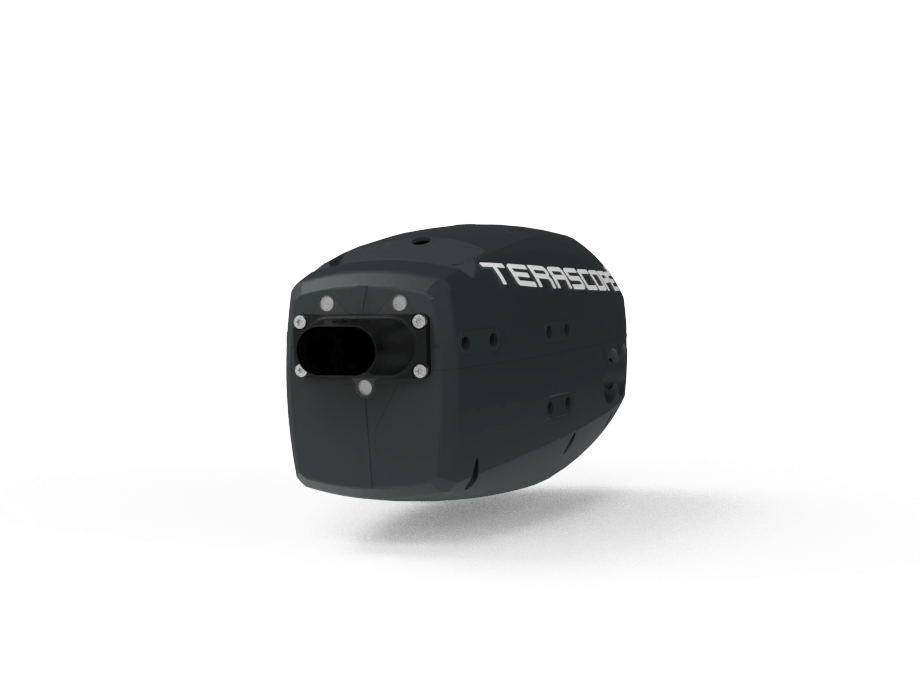

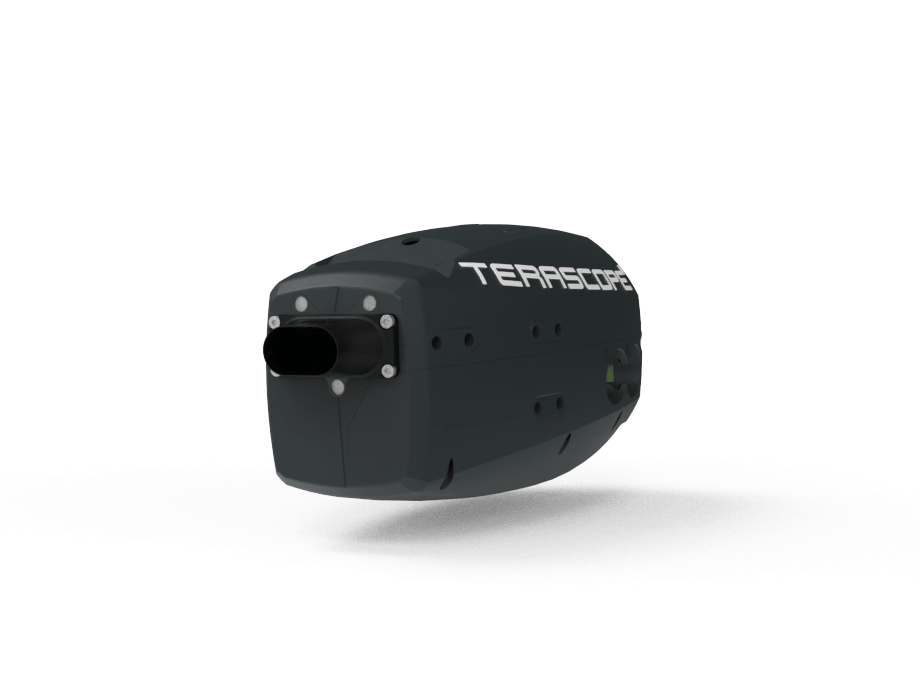

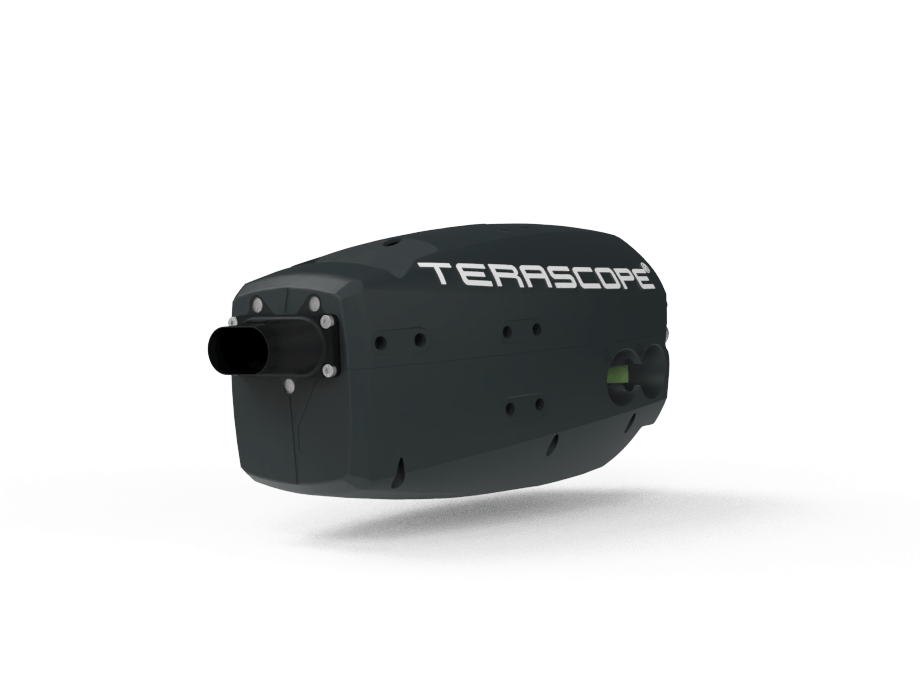

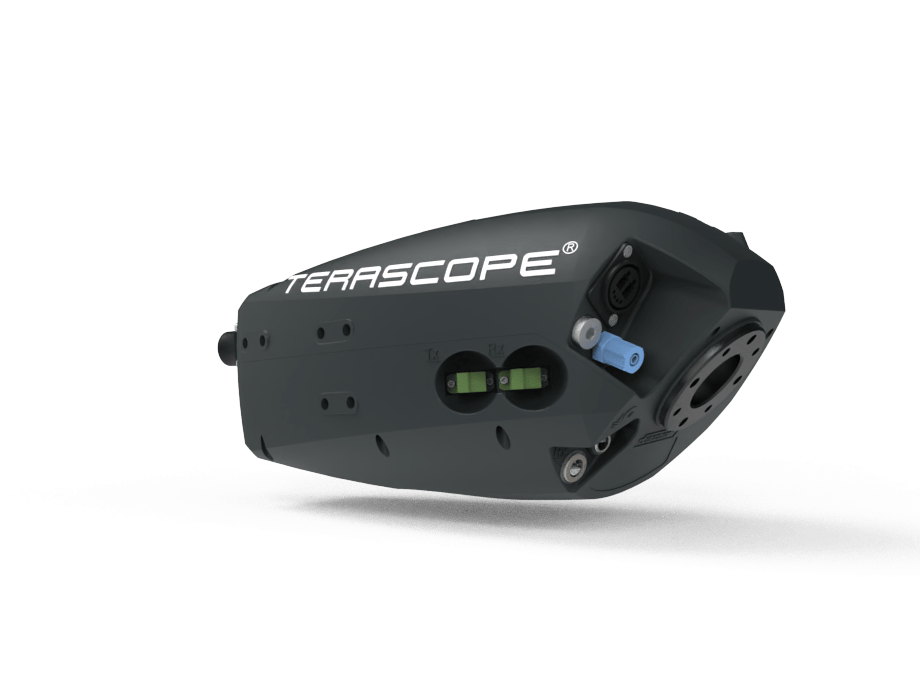

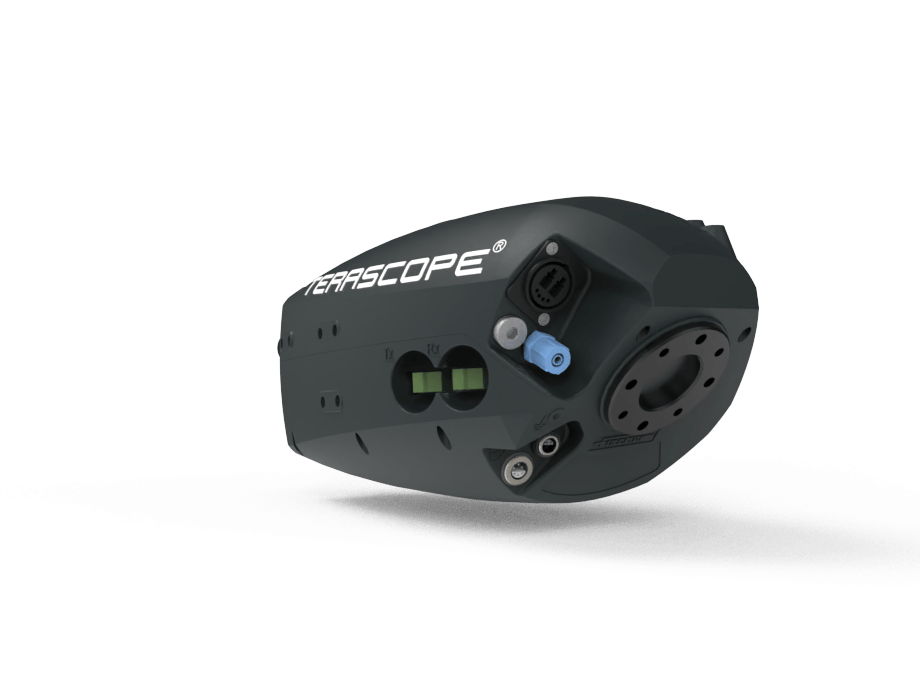

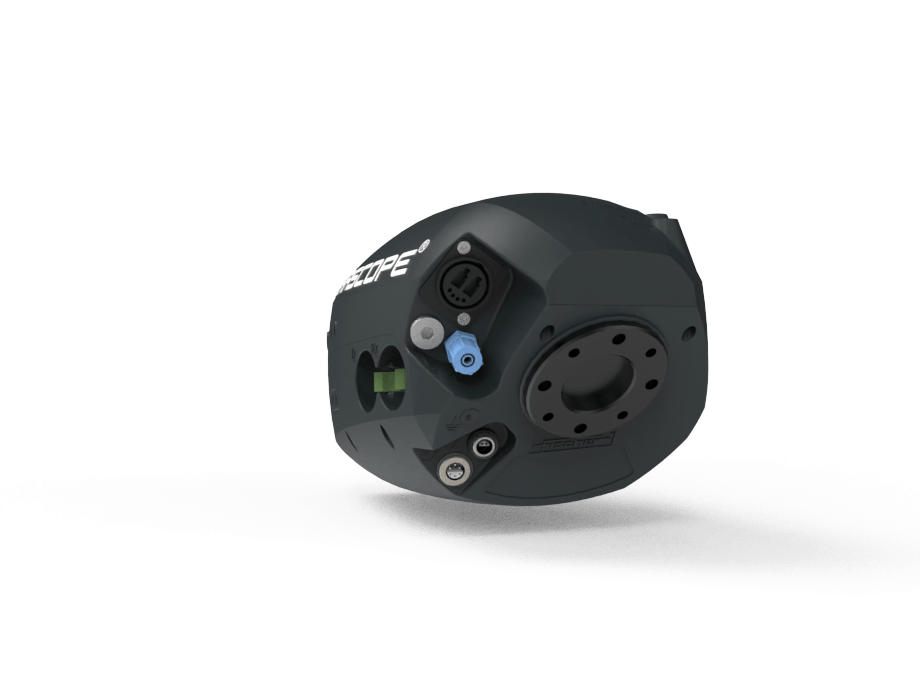

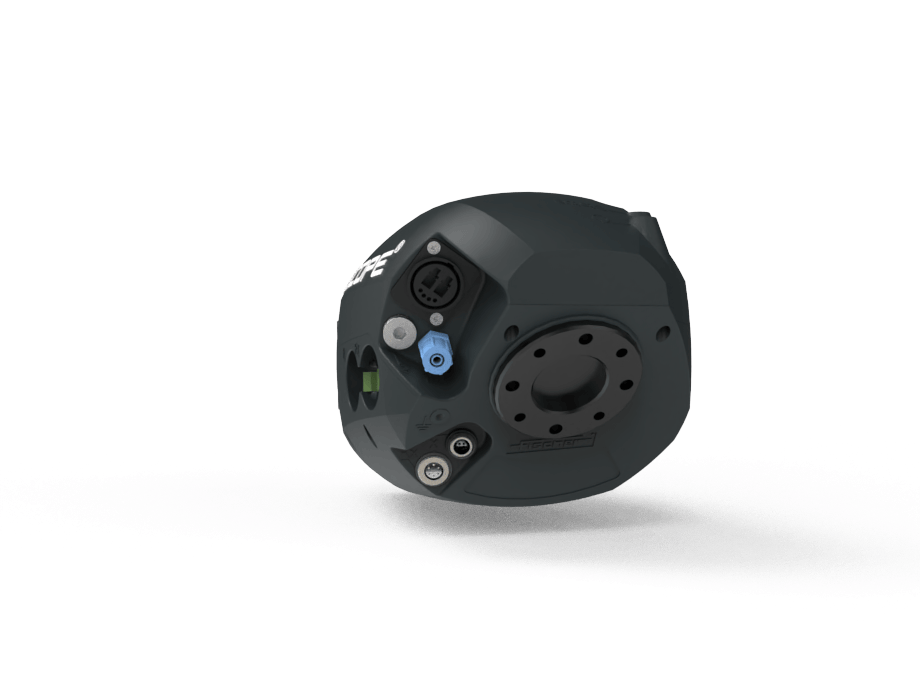

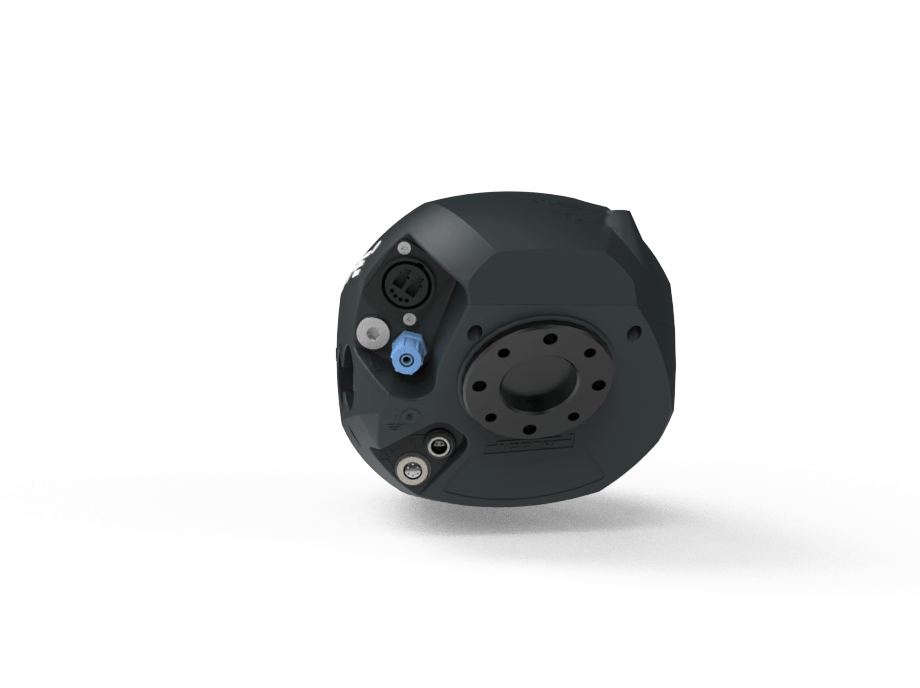

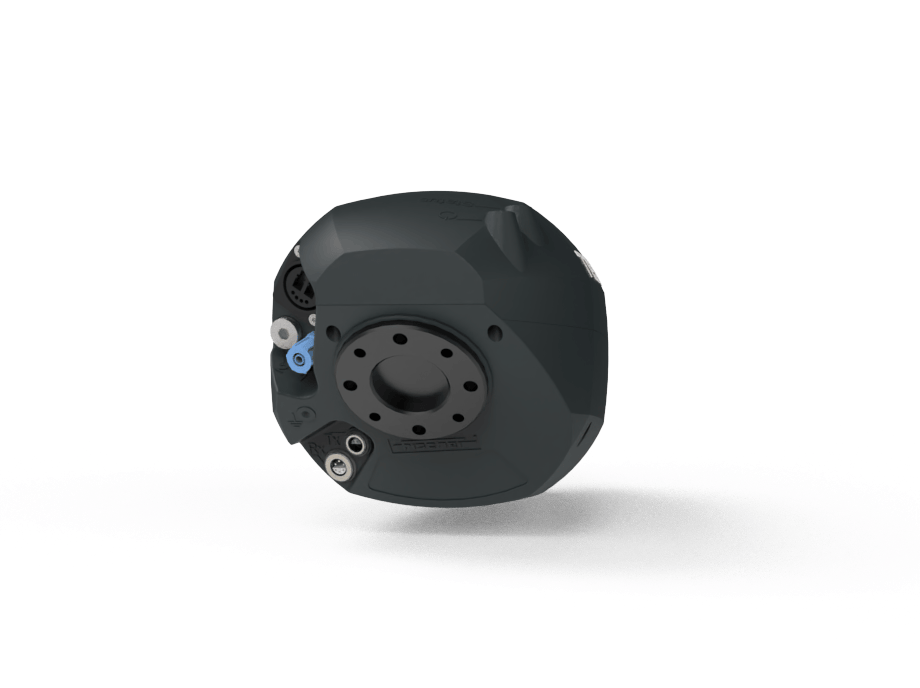

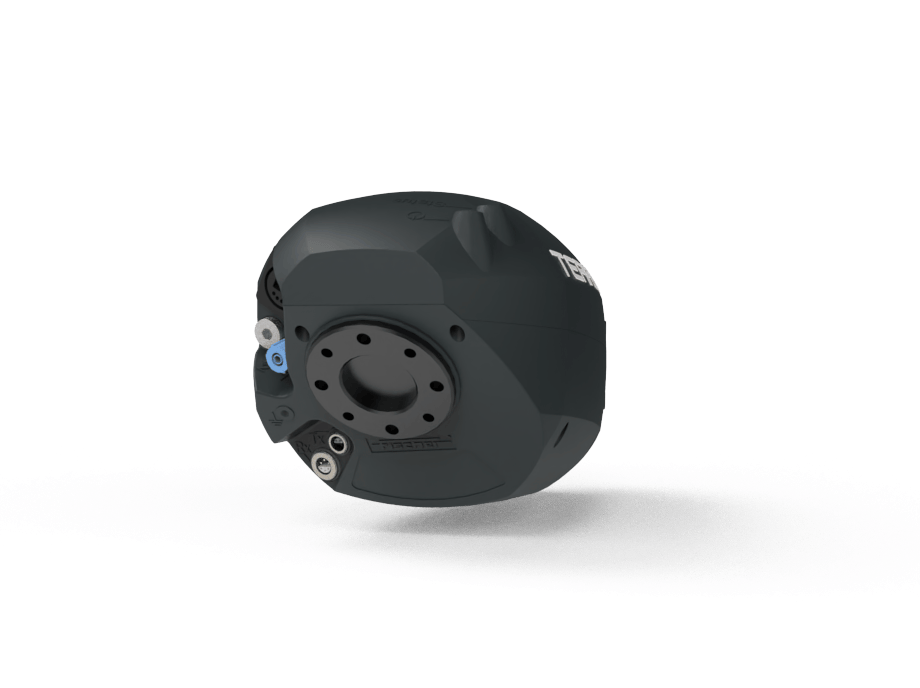

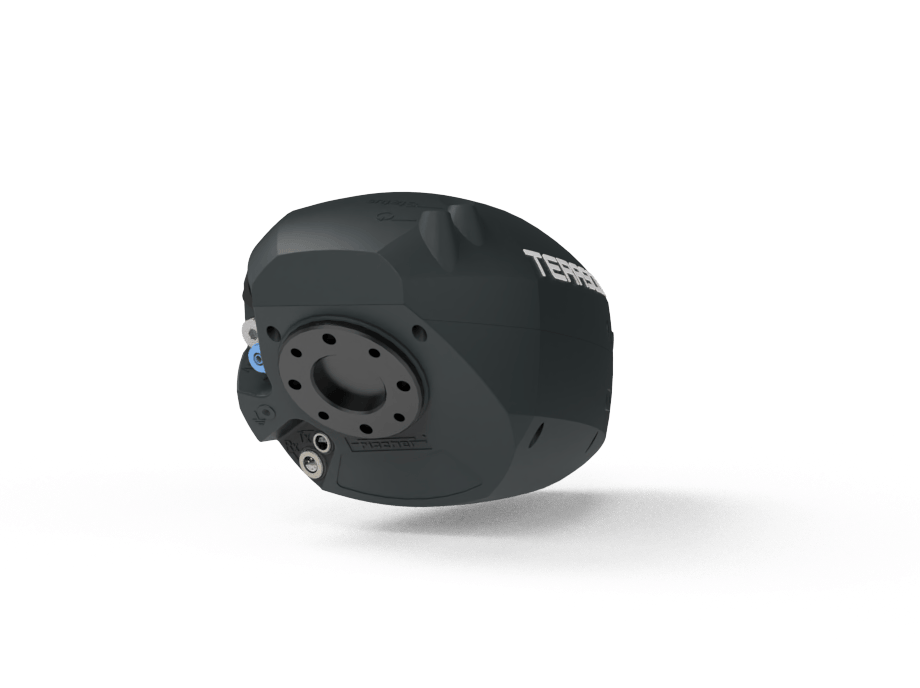

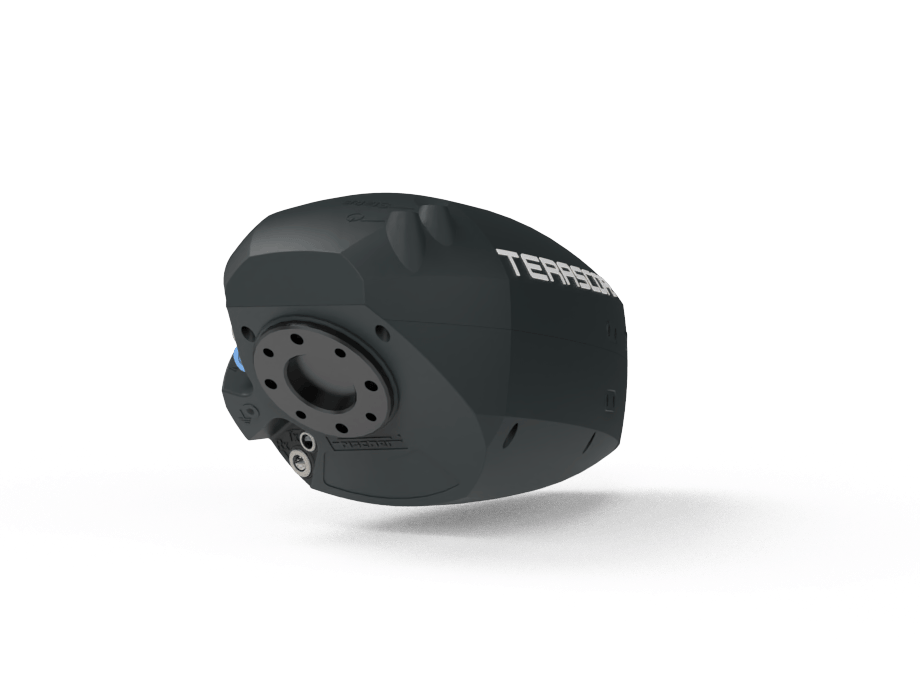

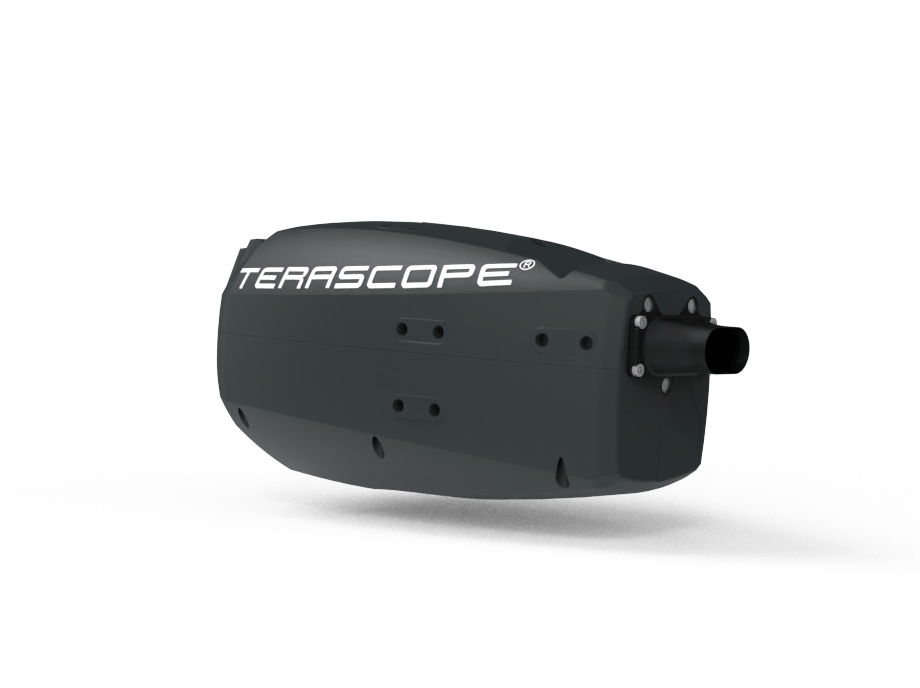

TERASCOPE®

6 THz bandwidth ¹

for market-leading measurement performance

sampling rate of 1.6 kHz ¹

¹ Depending on configuration.

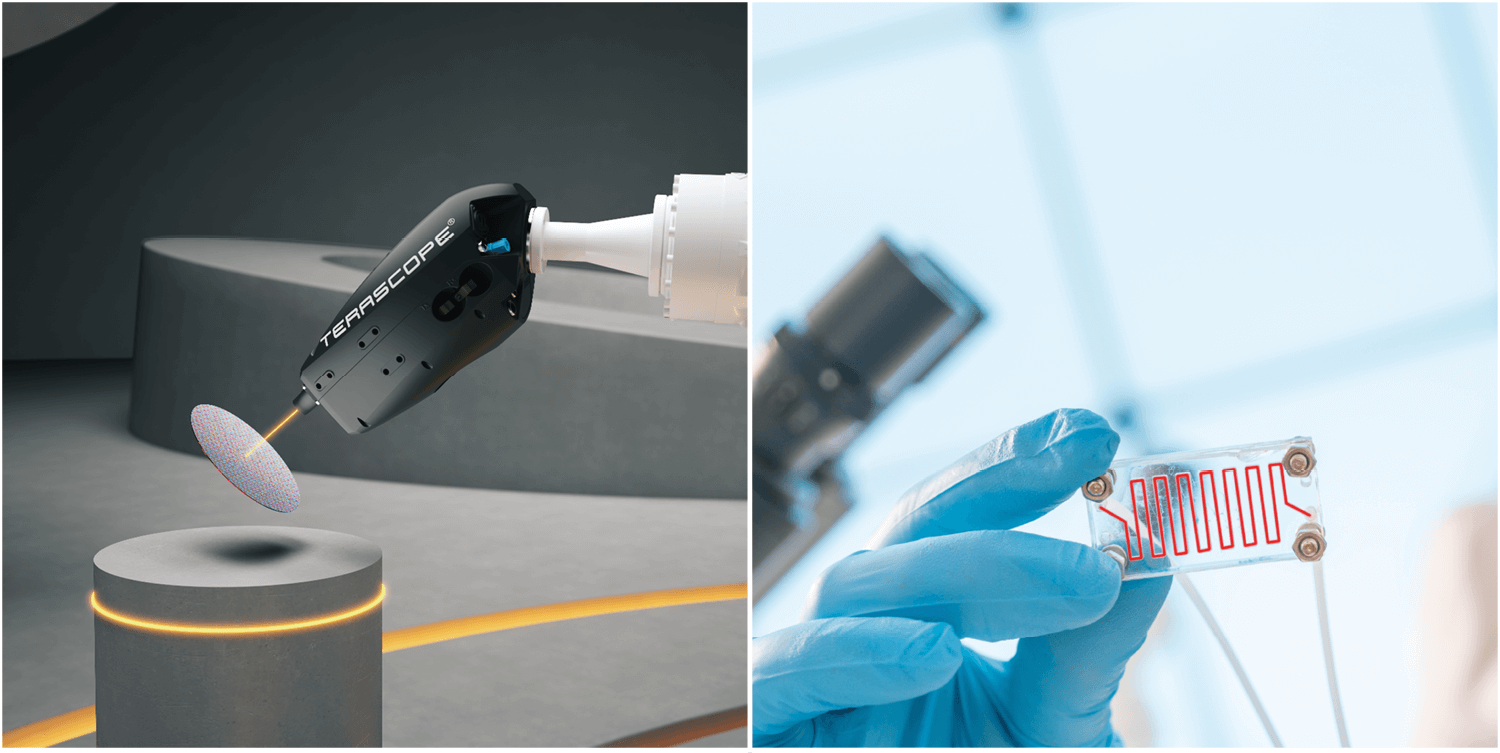

One solution, wide range of applications.

With market-leading precision, repeatability and speed, the innovative TERASCOPE® measurement system is perfectly suited for fully automated inline measuring. Absolutely non-destructive and contactless, the TERASCOPE® penetrates all organic and dielectric materials and can therefore be used for a wide variety of measuring tasks. Its modular design allows system manufacturers and integrators to integrate the measurement system flexibly and individually into the production process.

Market-leading measurement performance.

Up to 6 THz bandwidth* for highest precision and repeatability

Faster than any vibration.

Precise measurement results even in harsh environments thanks to uniquely high sampling rate of 1.6 kHz*

High reliability.

Robust, low-maintenance, developed for 24/7 operation

Low maintenance.

Less wear and tear due to electro-optical measurement

* Depending on configuration.

Patented Clean-Trace technology.

Continuous dry air purging for unadulterated measurement results

3D scanner.

High-precision positioning even on round surfaces and complex geometries

Easy integration.

Hardware and software designed for robot and control systems

Features

Bandwidth: Up to 6 THz, depending on configuration

Spot size: ⌀ 1 mm

Thickness of the layer(s): 10 μm to several millimeters

Integration, remote control and data export via fieldbus system

Sampling rate: 1.6 kHz, depending on configuration

Measuring distance: 7 cm

Measuring precision: Up to 1 μm, from 100 μm layer thickness up to 1 %, depending on the application

Measuring time: ⌀ 1 s

Number of layers: Up to 7, depending on material

Repeatability: < 0.1 μm

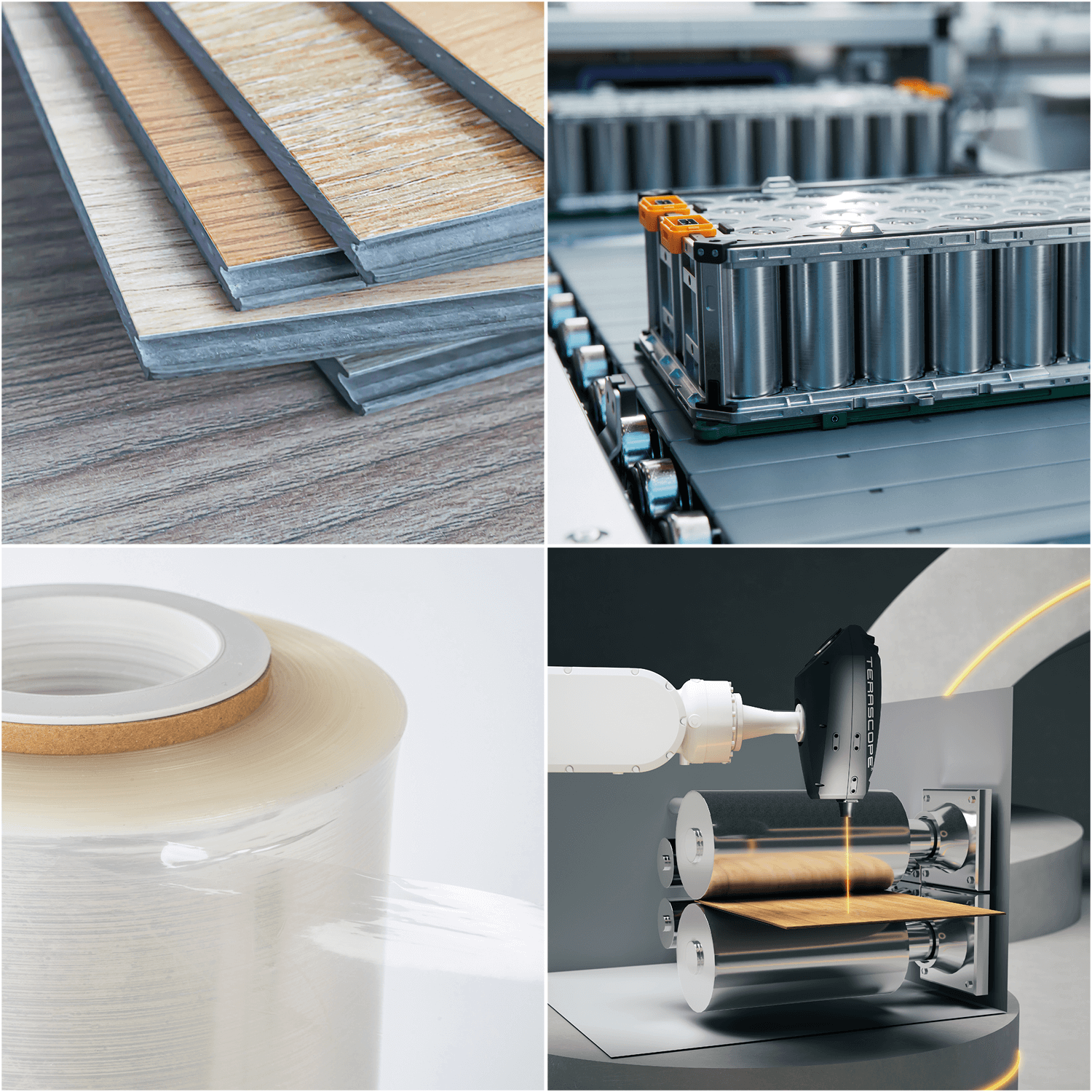

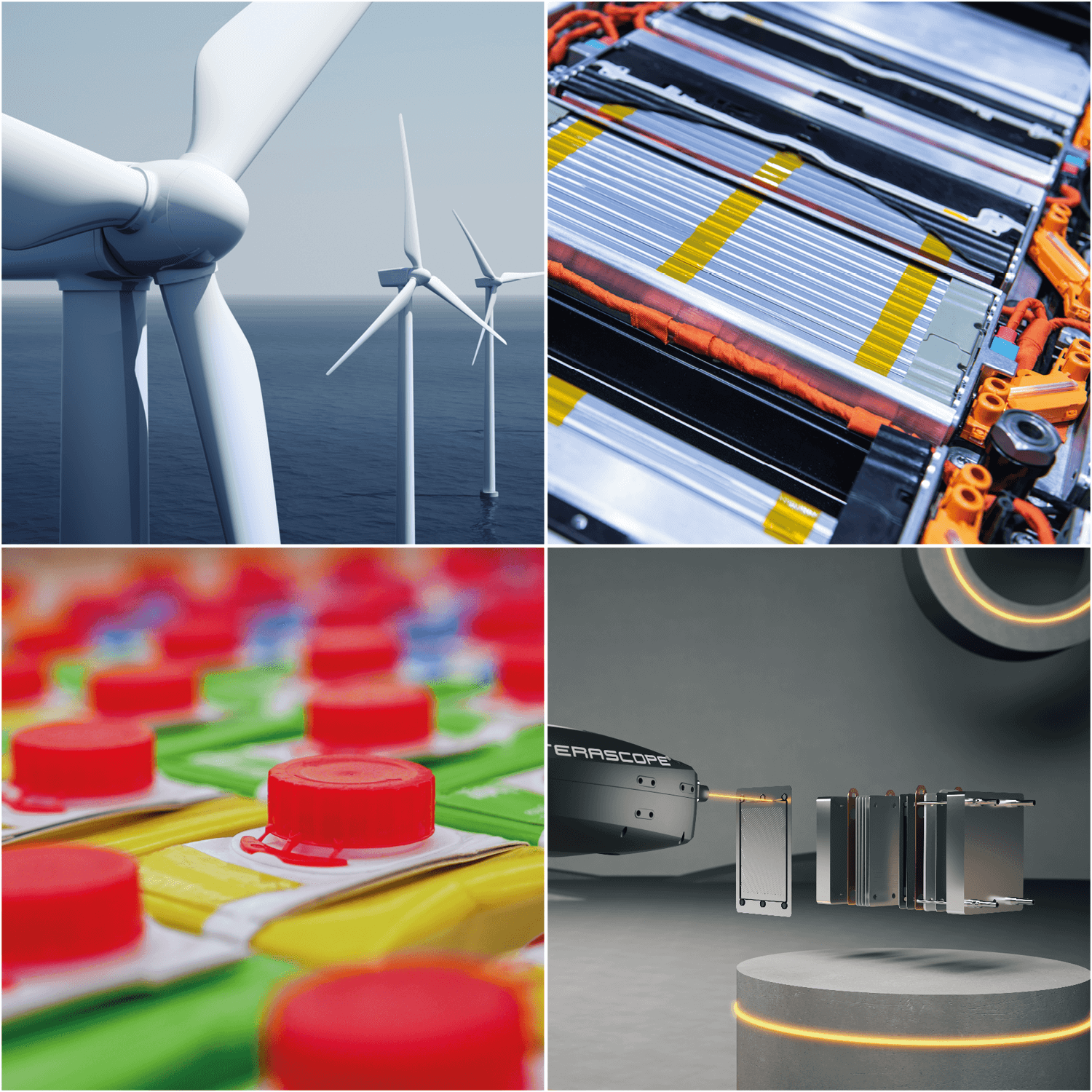

Application examples

Automotive

- Paints and lacquers on car bodies and add-on parts made of metal, plastic, or carbon such as spoilers and bumpers

- Slush skins on airbags

- Fabric and organic functional coatings on plastic composite parts in the interior

- Battery foils

- Bipolar plates for fuel cells

- And much more

- Painted add-on parts made of plastic such as bumpers

Coating thickness measurement of single and multilayer systems including detection of invisible defects and hidden corrosion

Determining of radar transmission and reflection

Polymers and plastic extrusion

- Battery foils

- Packagings

- Polymer functional layers such as EVOH

- Coextruded floor boards and films

- Bipolar plates for fuel cells

- All coated functionally- and safety-critical components made of plastic, polymers, or composite materials

- And much more

Coating thickness measurement of single or multilayer systems including detection of invisible defects and inclusions

Semiconductor

- Electrical conductivity

- Layer resistance

- Mobility of free charge carriers (2DEG)

- Density of charge carriers

- Refractive index and extinction coefficient

- Absorbed power

- Single frequency characteristics

Testing of material properties

For applications such as wafers and in the fields of biosensor technology, photovoltaics and many more.

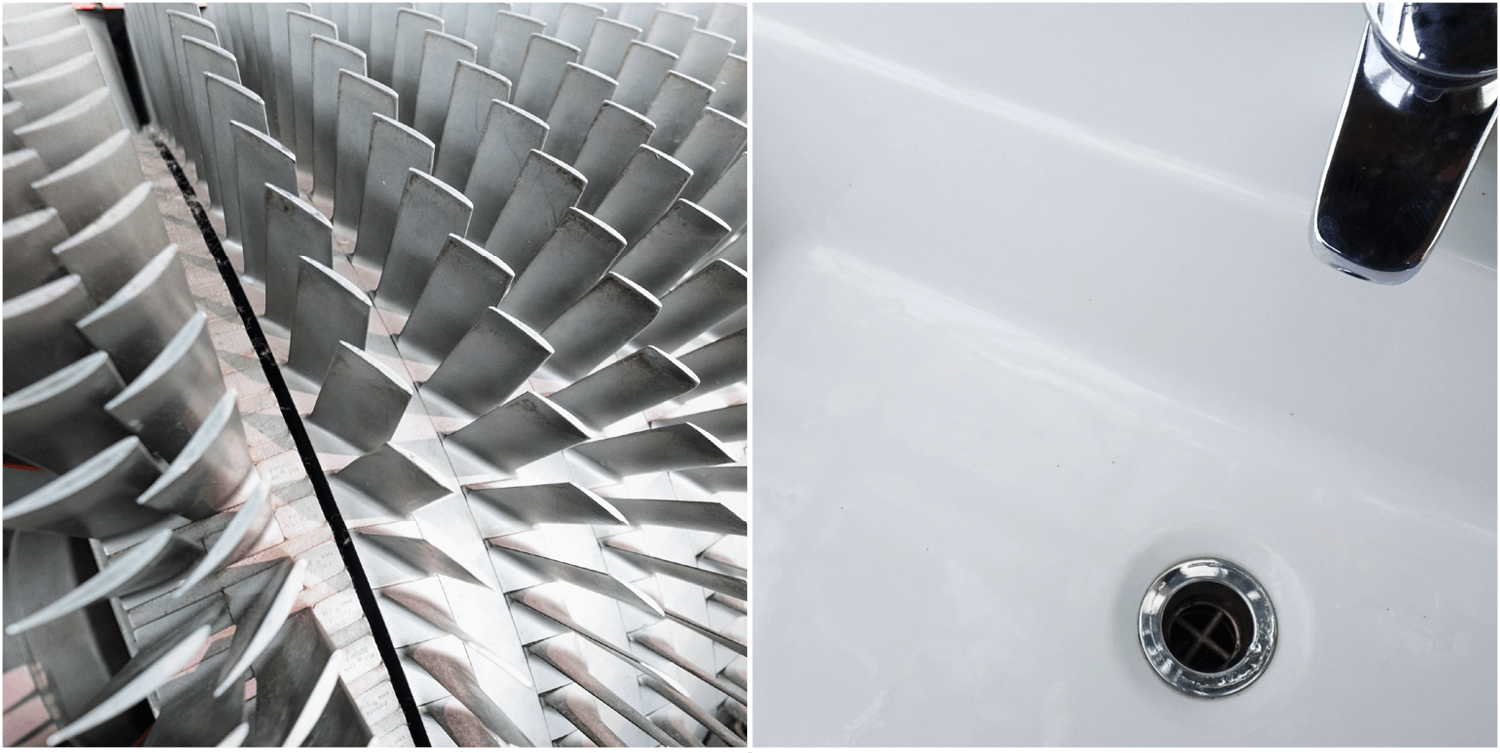

Aerospace

- Paints and lacquers on various aircraft parts made of epoxy resin or epoxy-glass resin such as fuselage and wings

- Thermal barrier coatings on turbine blades

- All coated functionally- and safety-critical components made of composite materials or metal

- And much more

Coating thickness measurement of single or multilayer systems including detection of invisible defects and hidden corrosion

Ceramics

- Ceramic and enamel coatings on ceramics, for example in the sanitary sector

- Ceramic coatings on metal, for example in the aerospace sector as thermal barrier coatings on turbine blades

Coating thickness measurement of single or multilayer systems including detection of invisible defects

Environment

- Battery foils

- Packagings

- Bipolar plates for fuel cells

- All coated functionally- and safety-critical components made of plastic, composite materials, or metal for wind turbines or photovoltaics

- And much more

Coating thickness measurement of single or multilayer systems including detection of invisible defects and inclusions

Material

- Wear protection such as diamond-like carbon (DLC)

- Packagings

- Paints and lacquers on paper and sheet metal, including special inks on paper, for example for printing money

- And much more

- Electrical conductivity

- Layer resistance

- Mobility of free charge carriers (2DEG)

- Density of charge carriers

- Refractive index and extinction coefficient

- Absorbed power

- Single frequency characteristics

Coating thickness measurement of single or multilayer systems

Testing of material properties

For applications such as wafers and 2D materials (e. g. graphene in photovoltaics), paints, lacquers, and special inks for printing money and many more.

Do you have other applications? Then contact us!