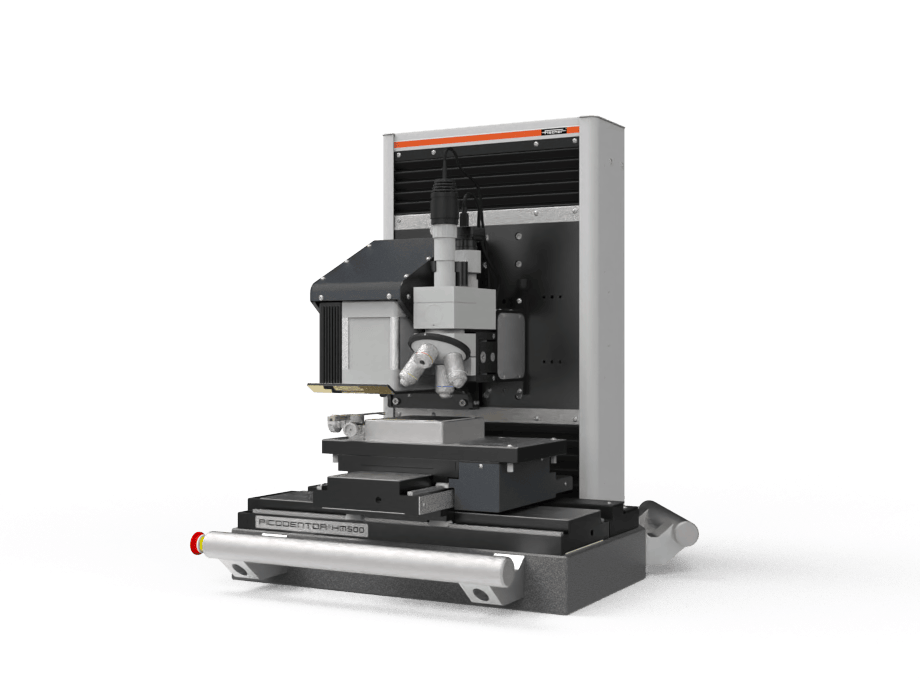

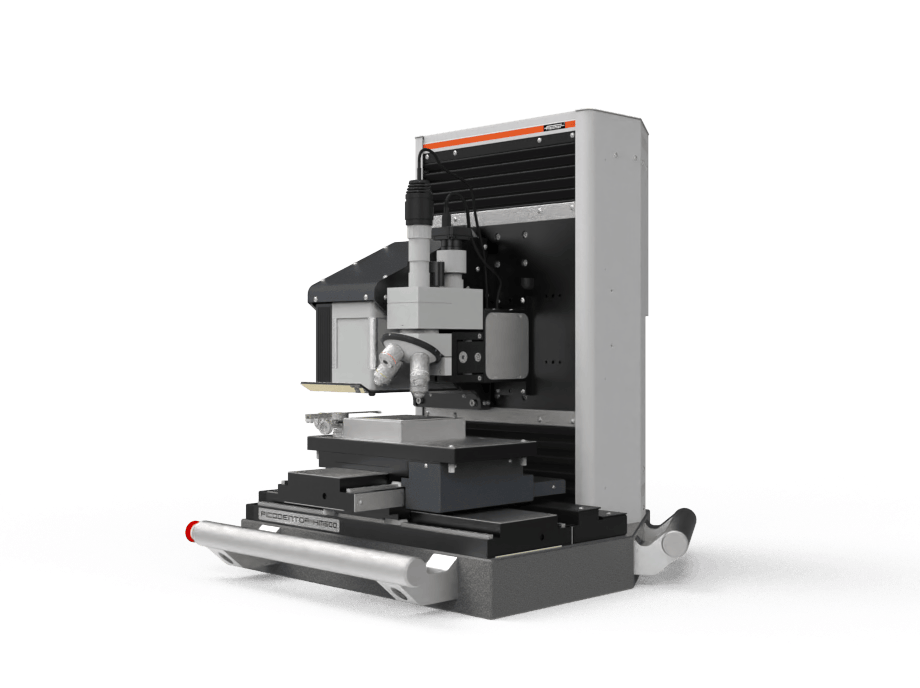

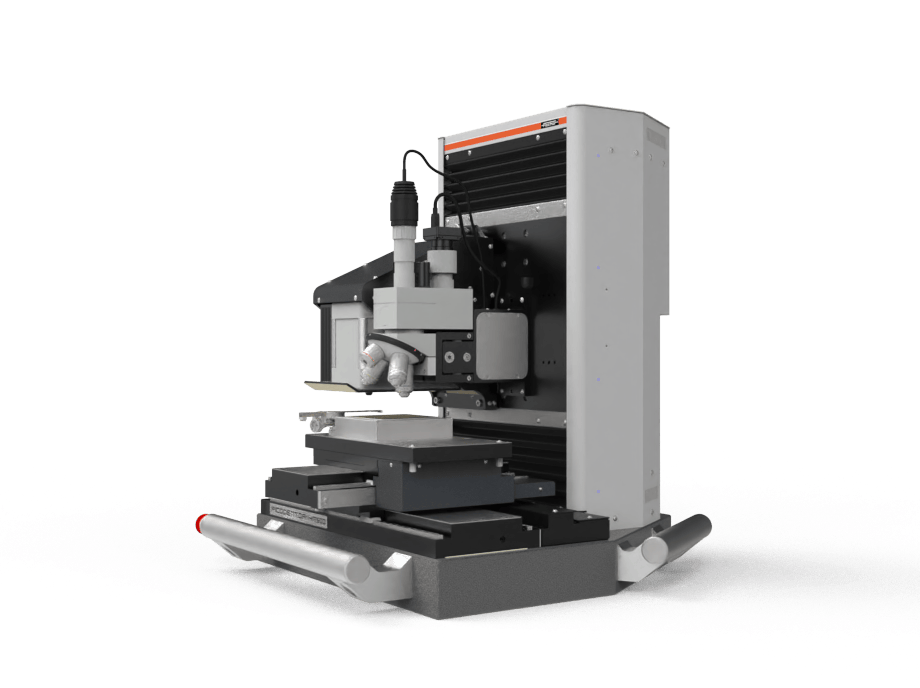

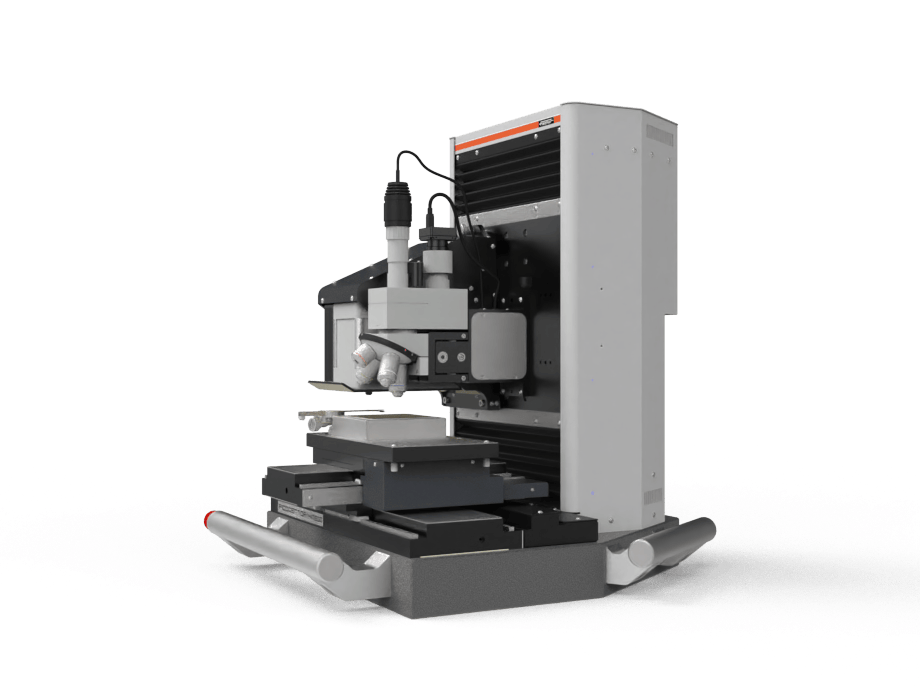

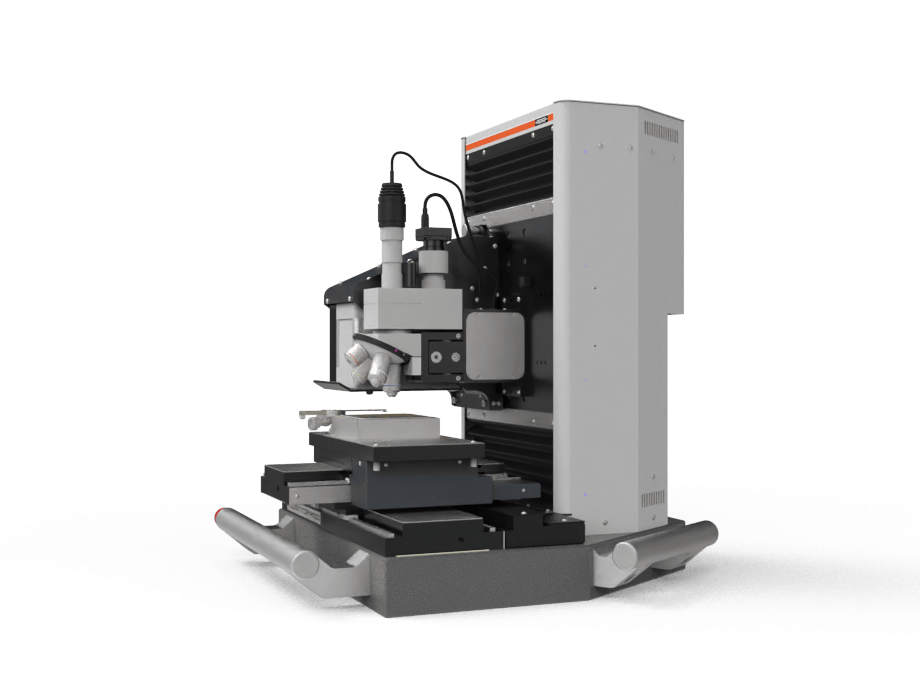

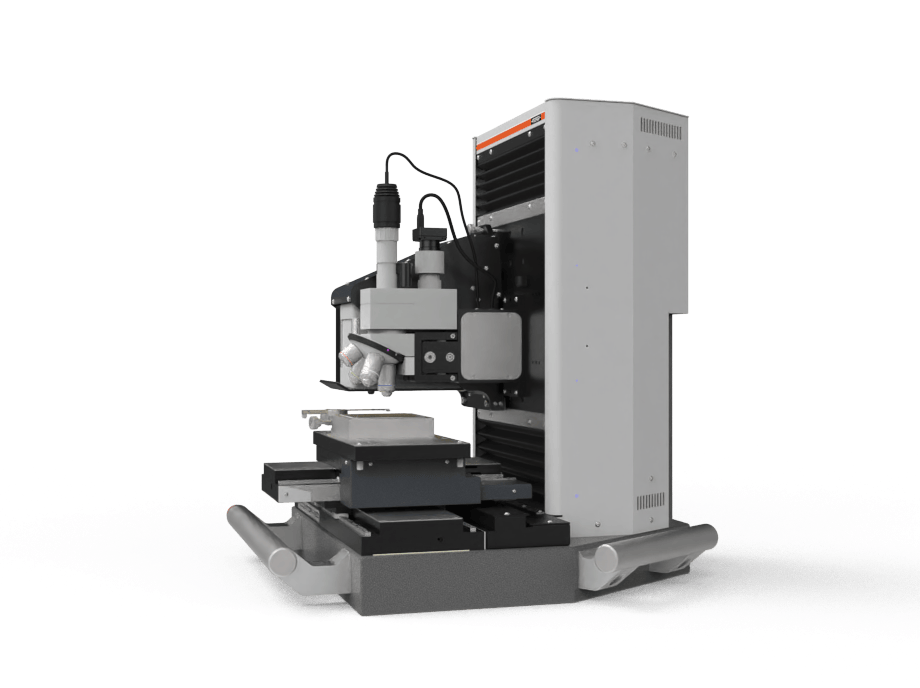

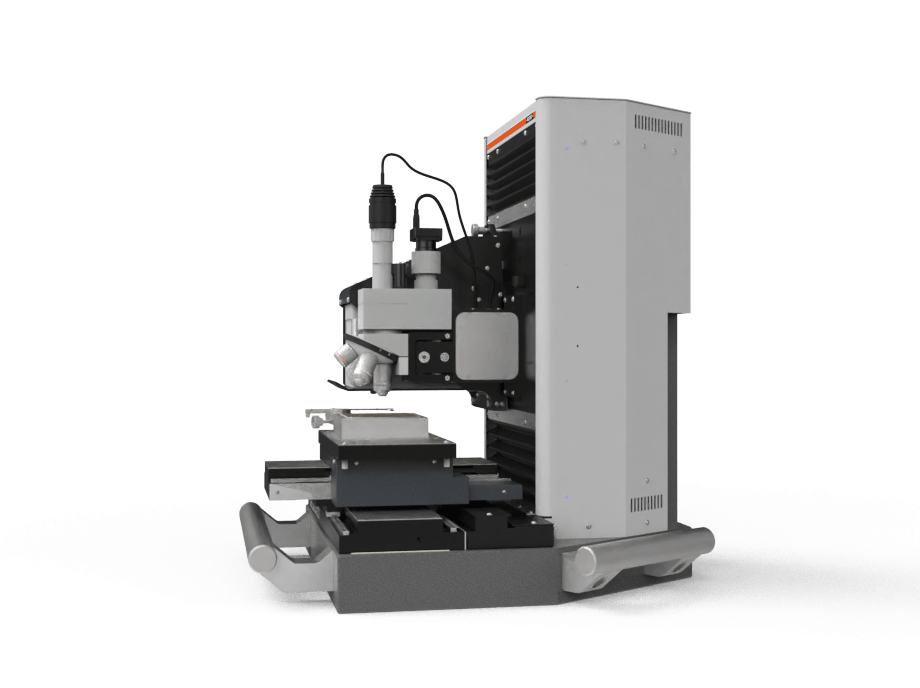

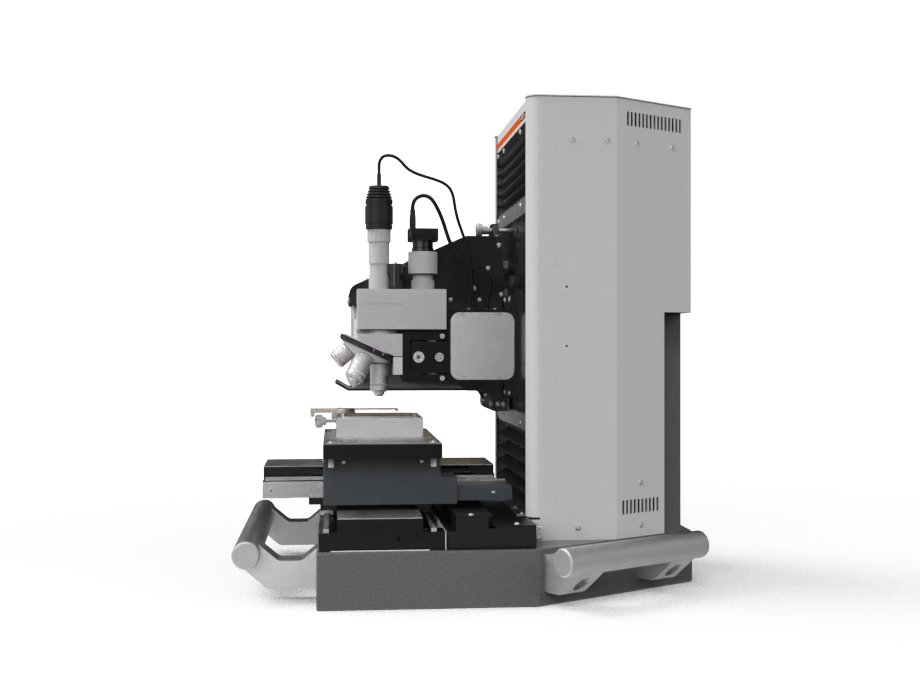

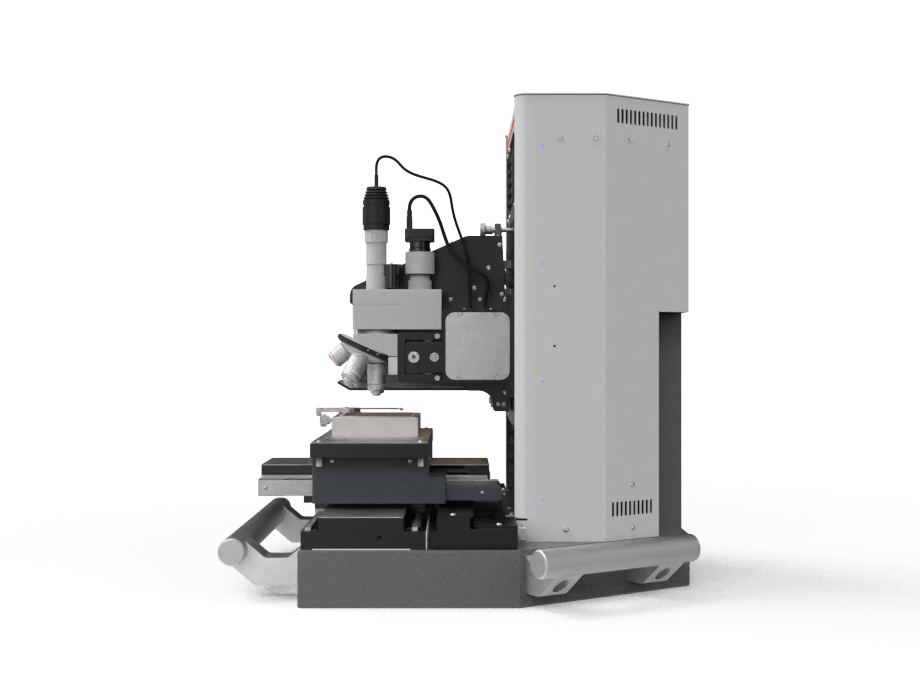

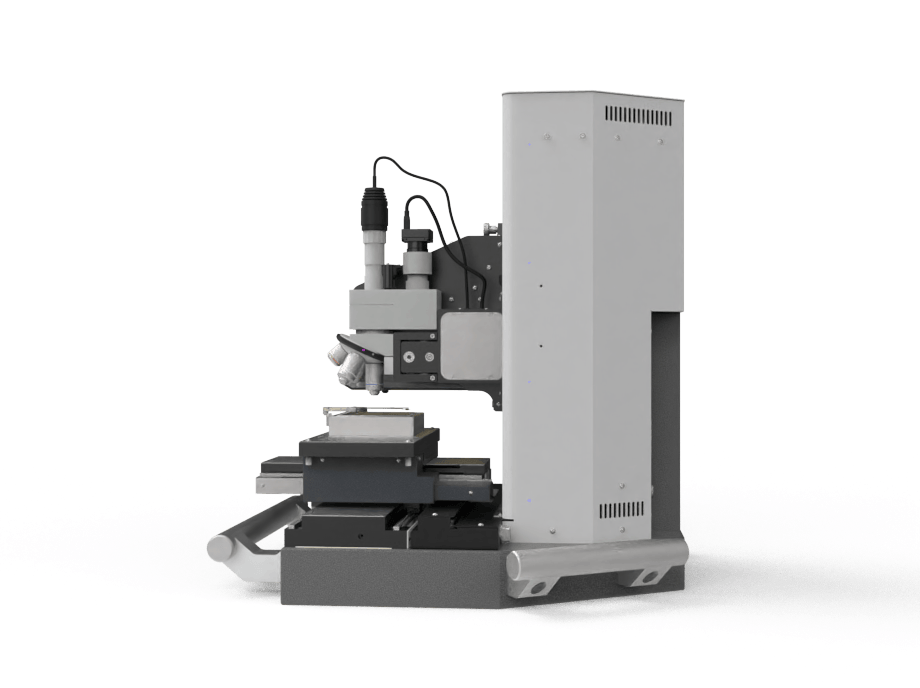

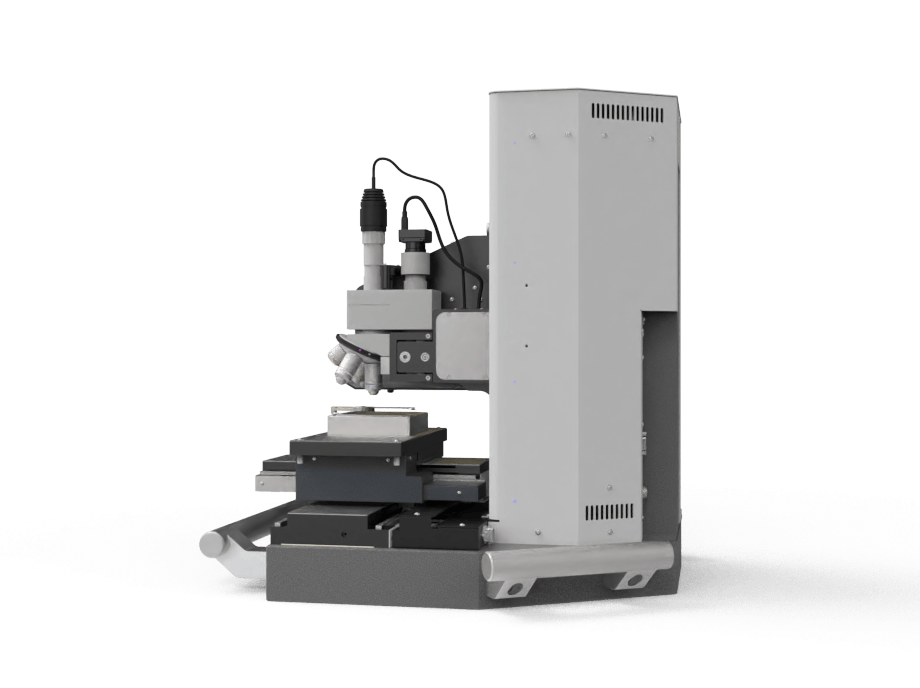

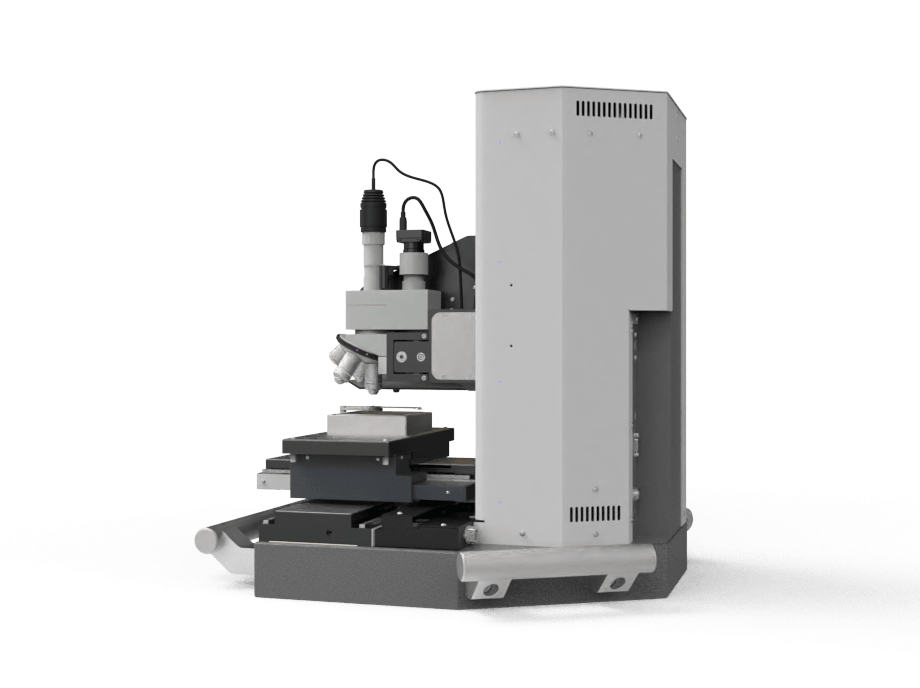

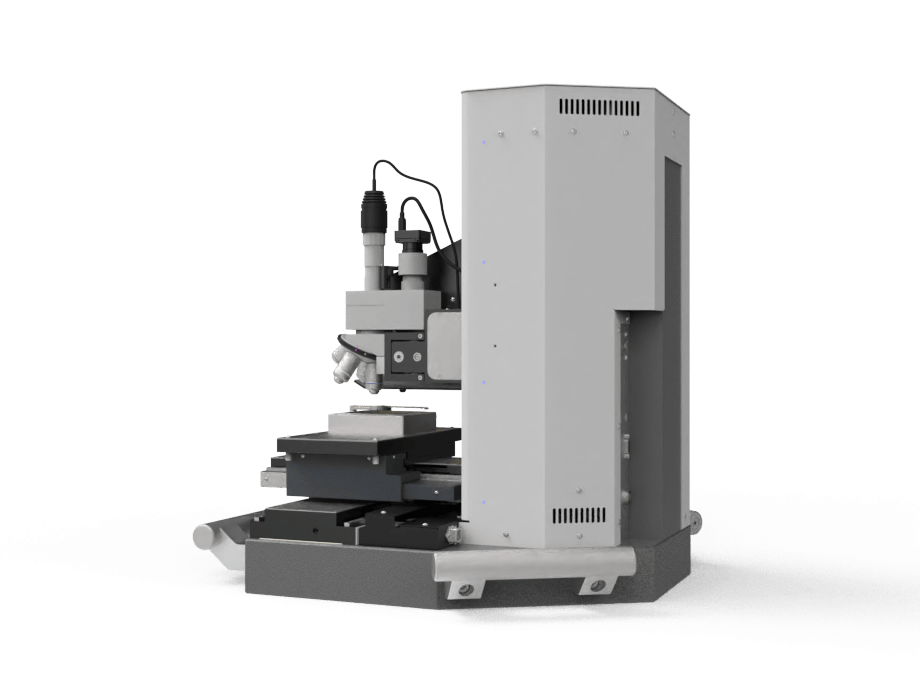

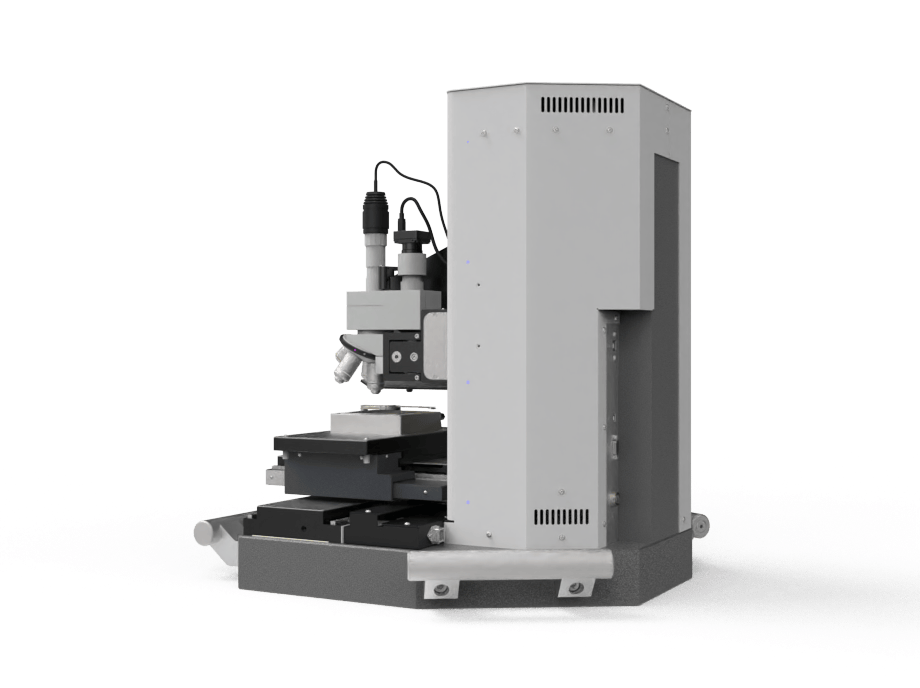

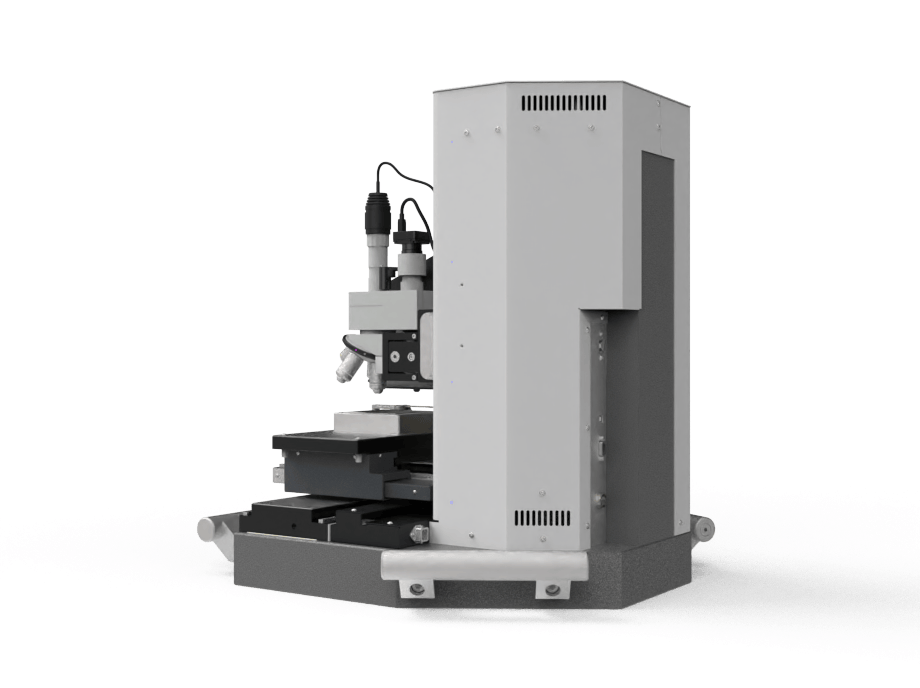

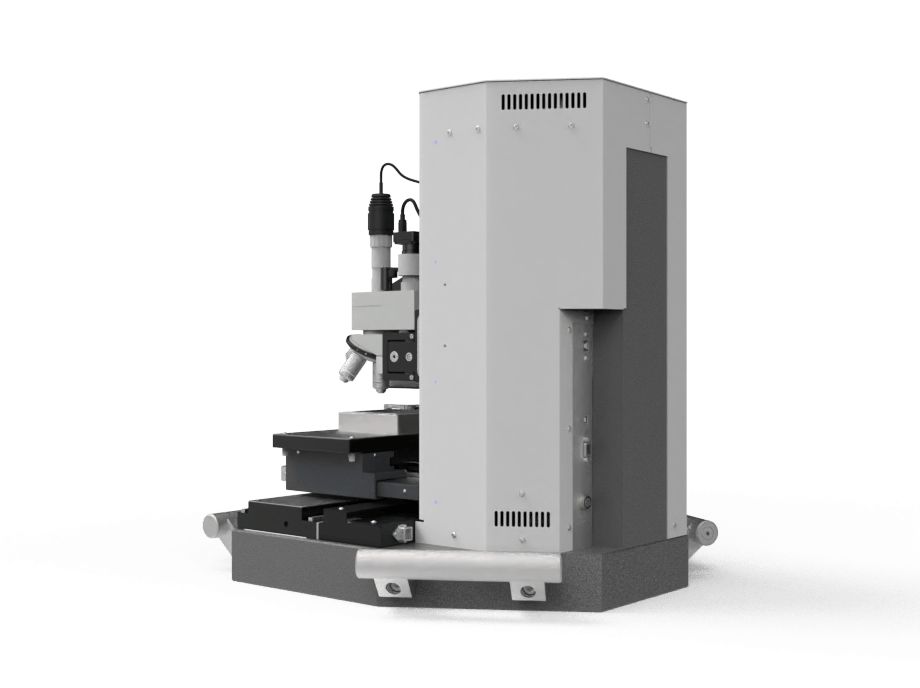

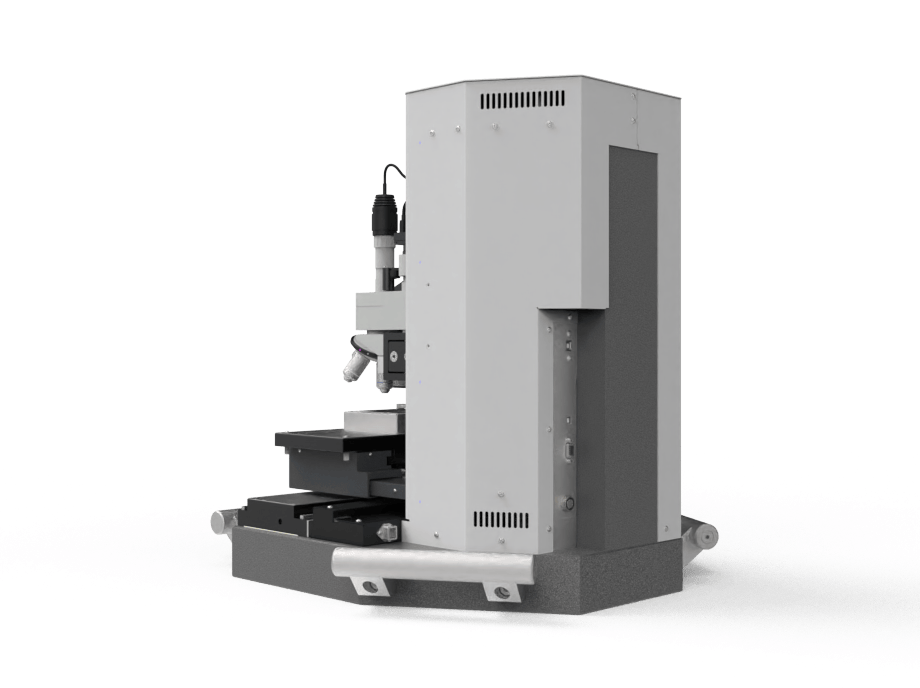

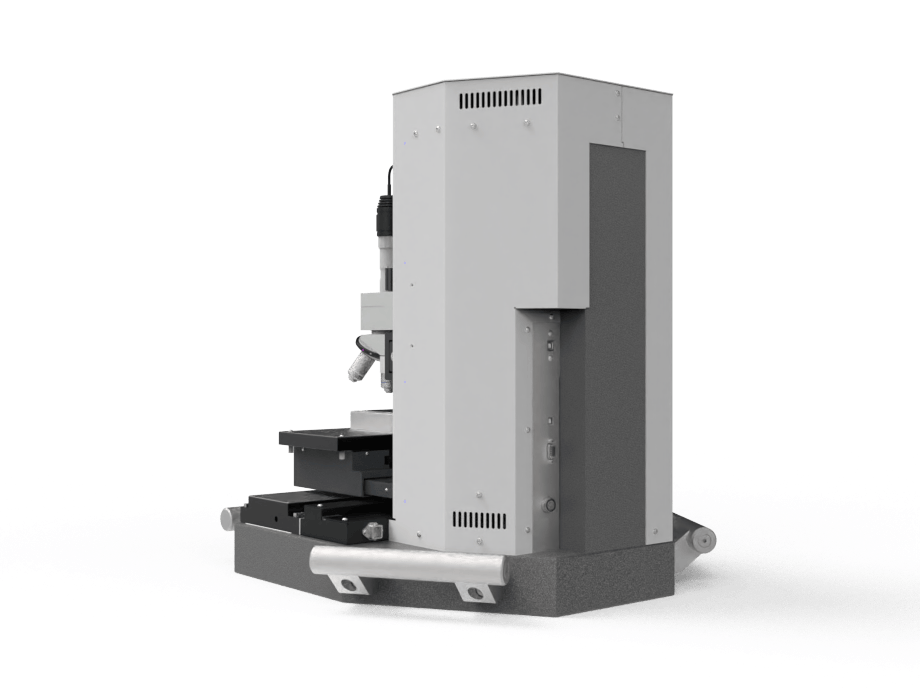

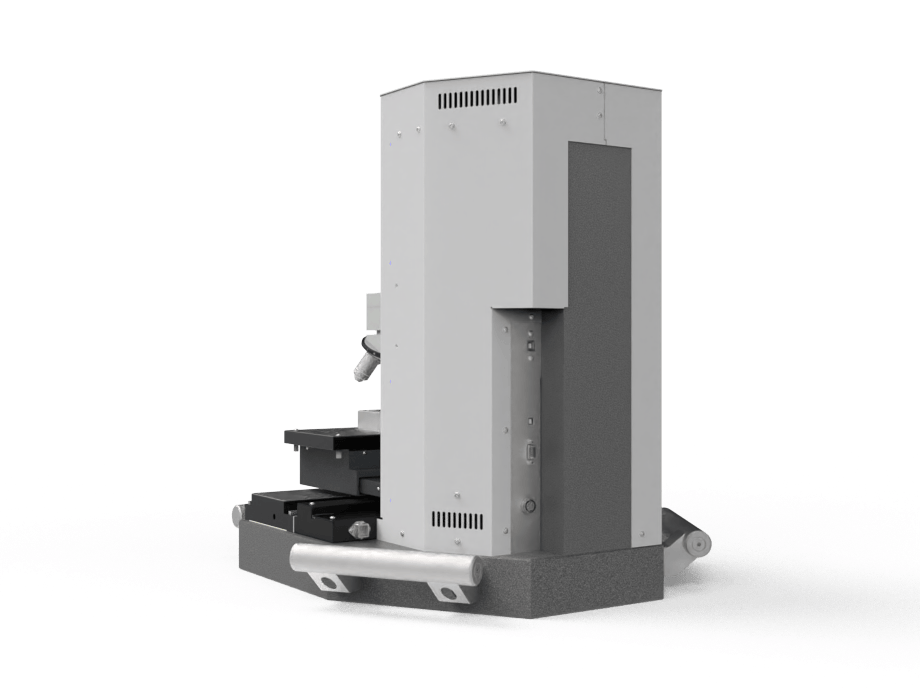

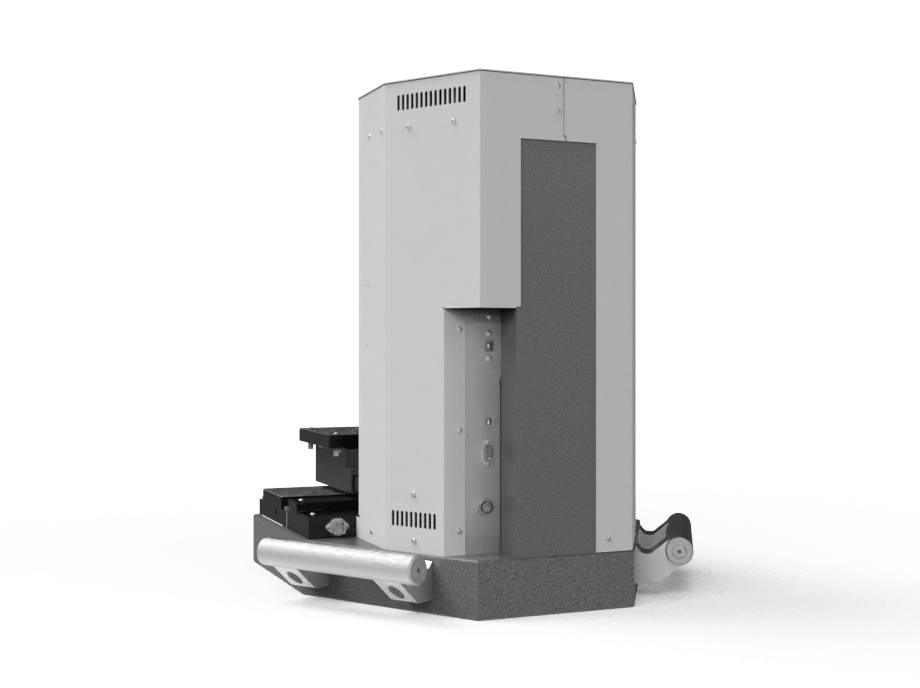

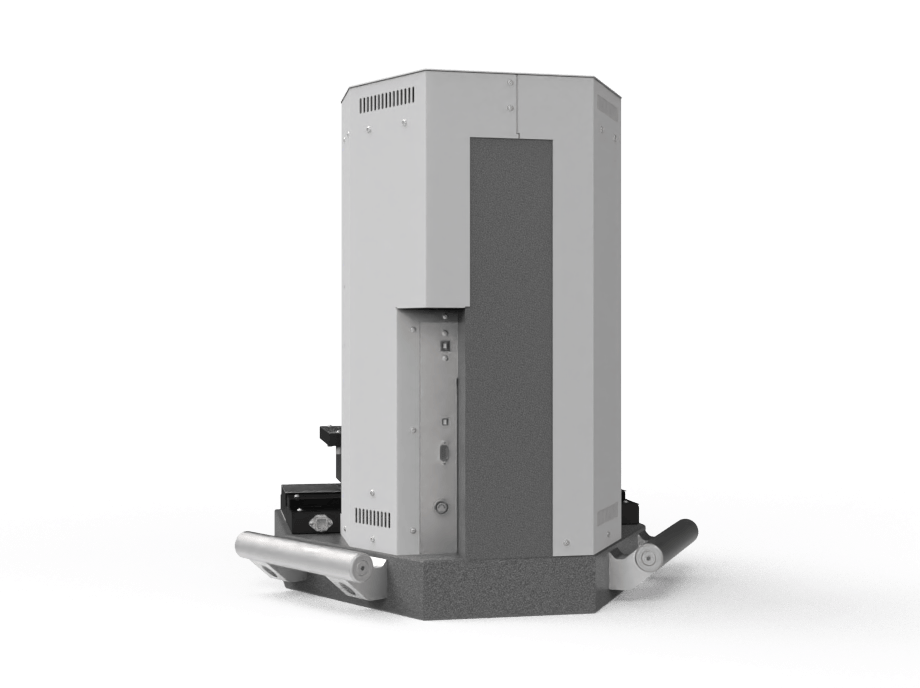

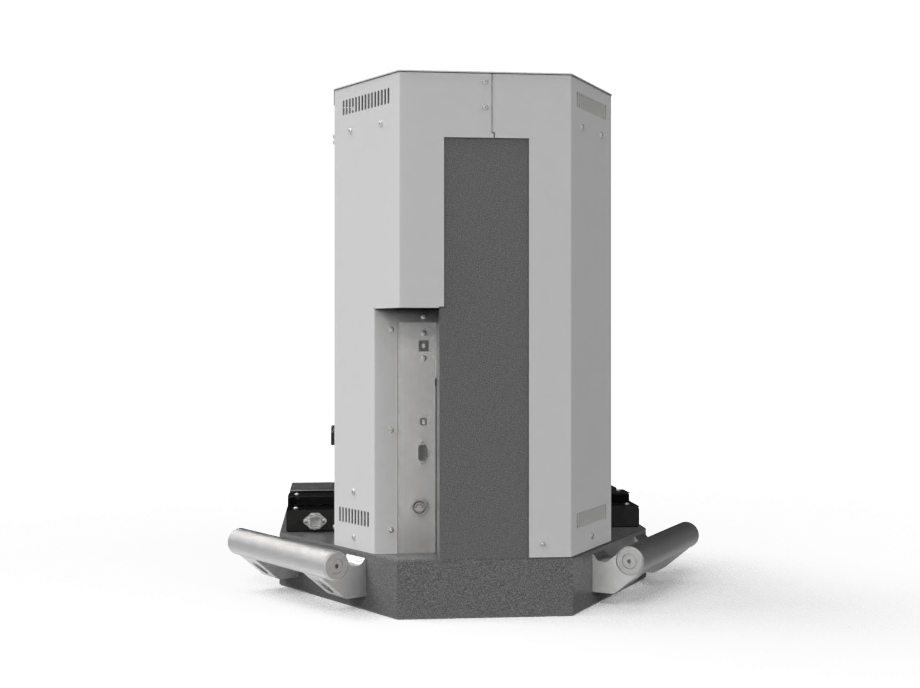

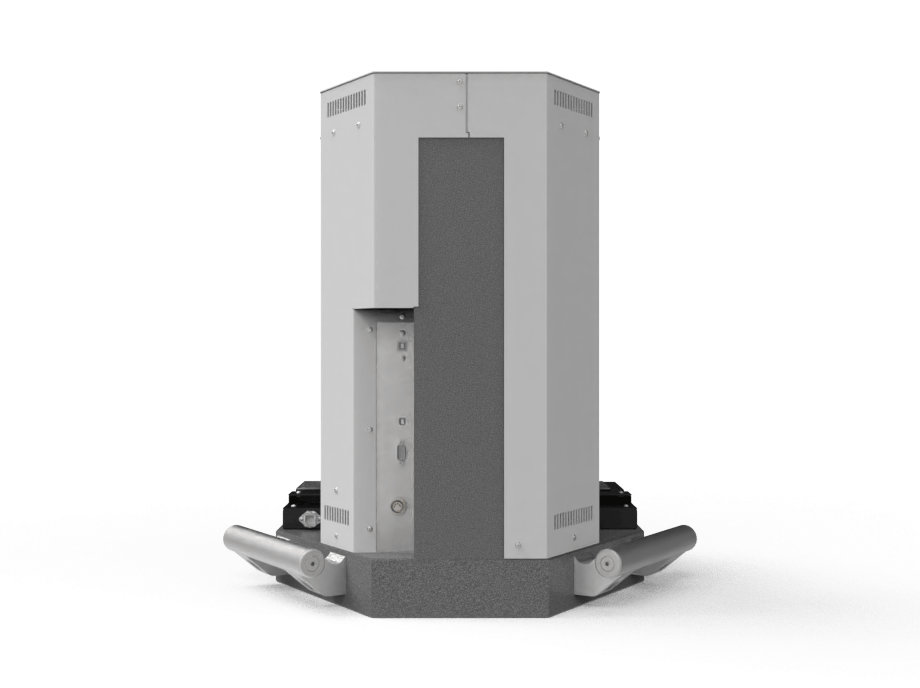

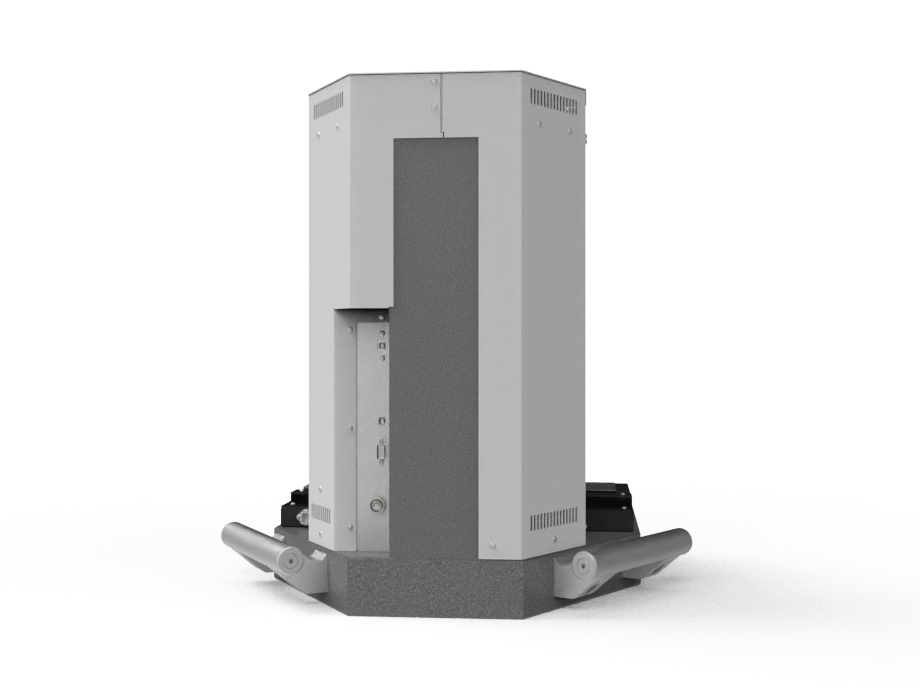

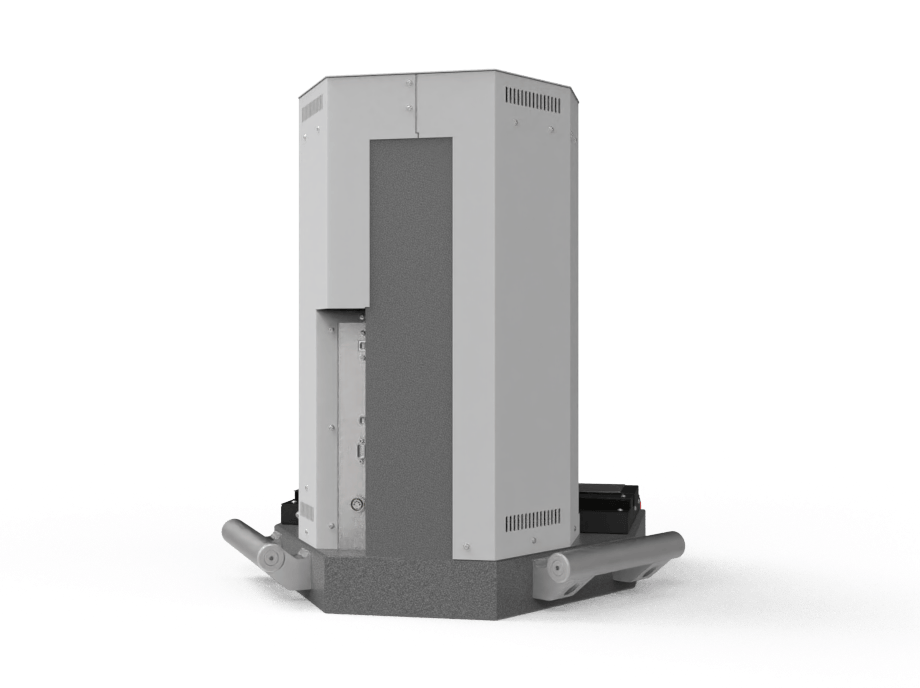

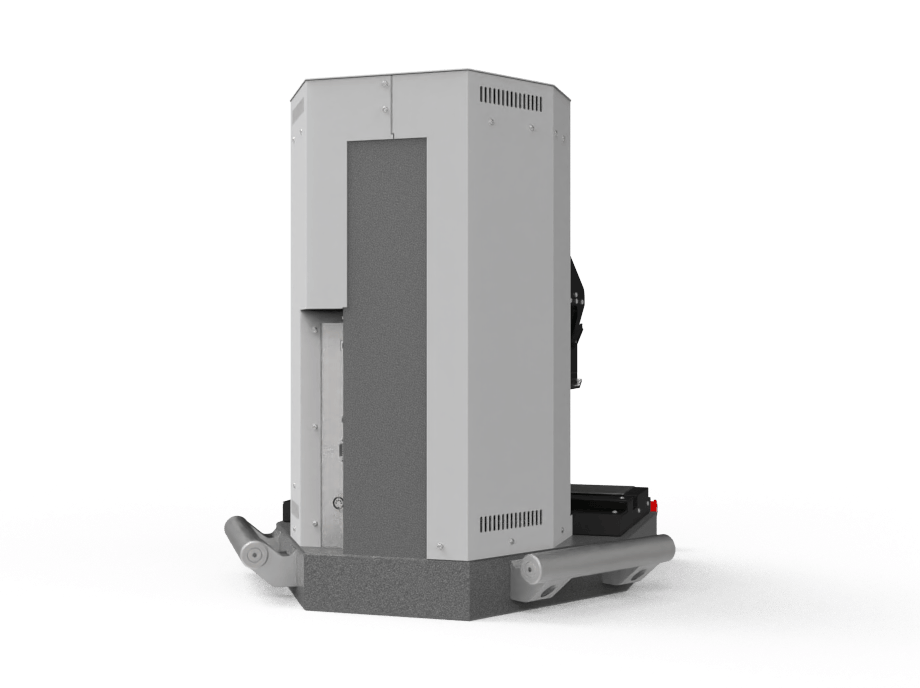

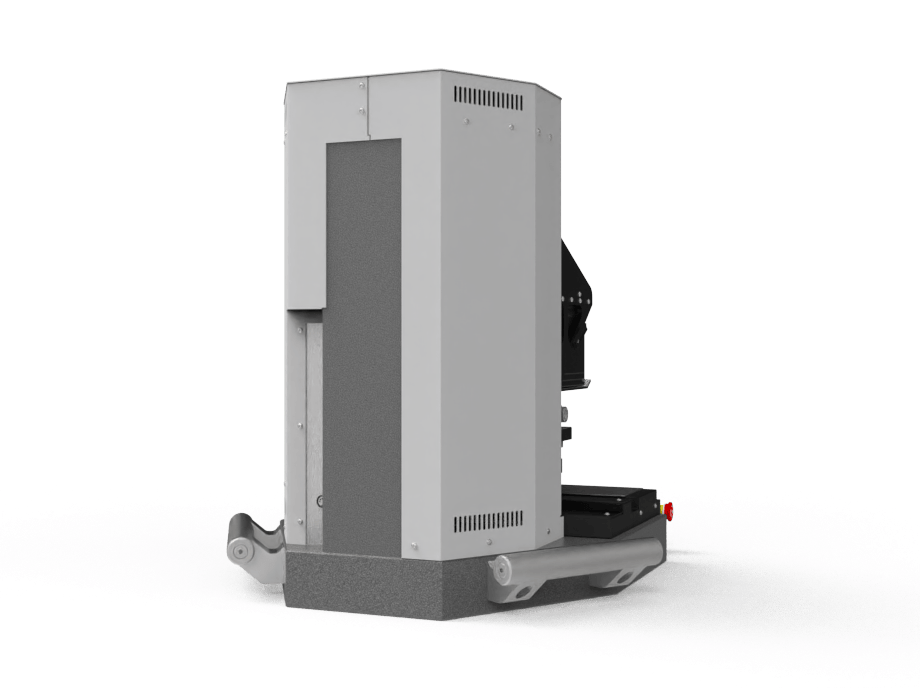

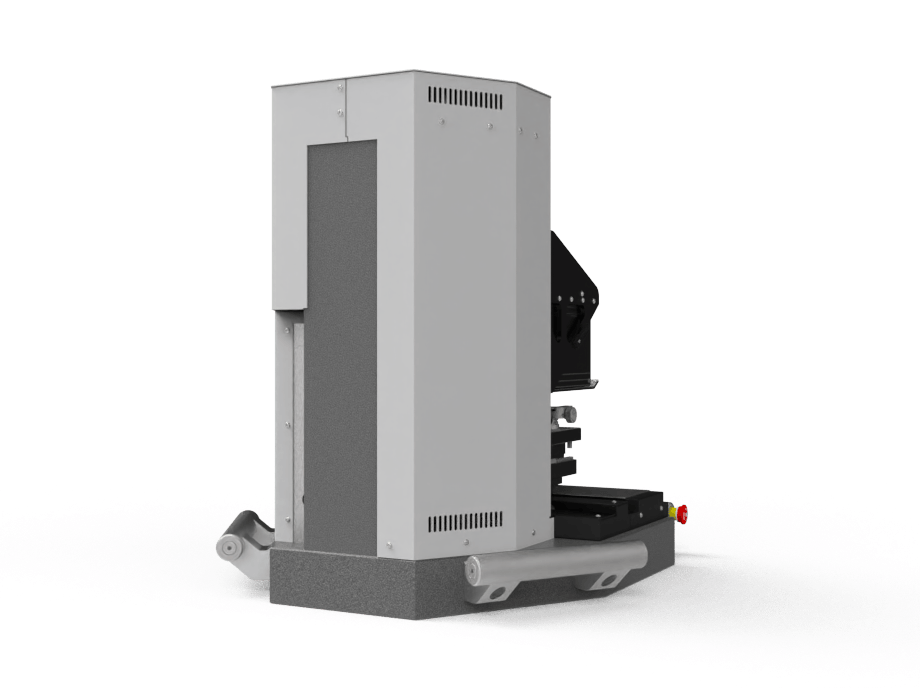

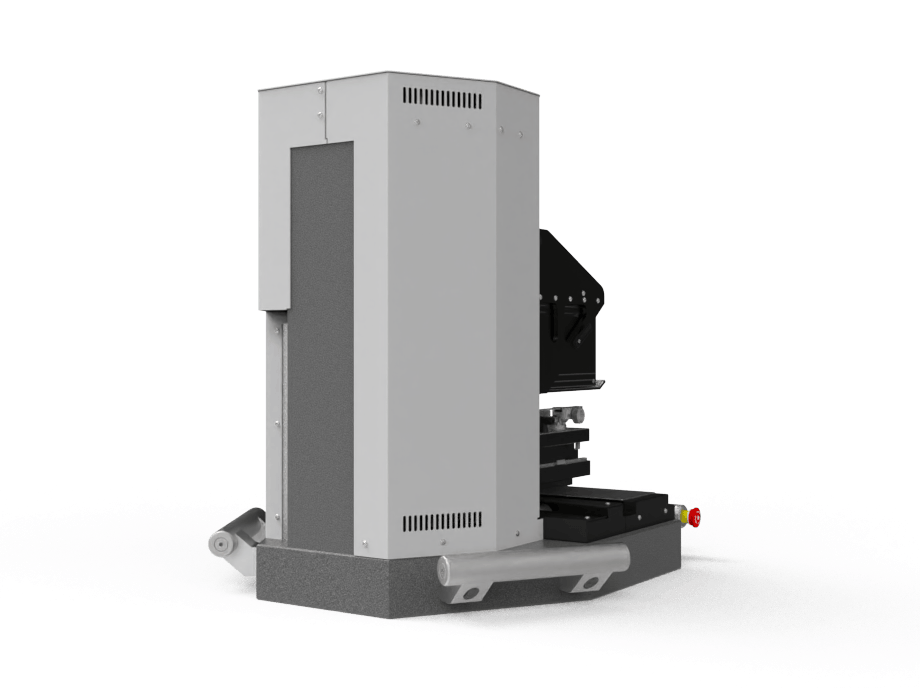

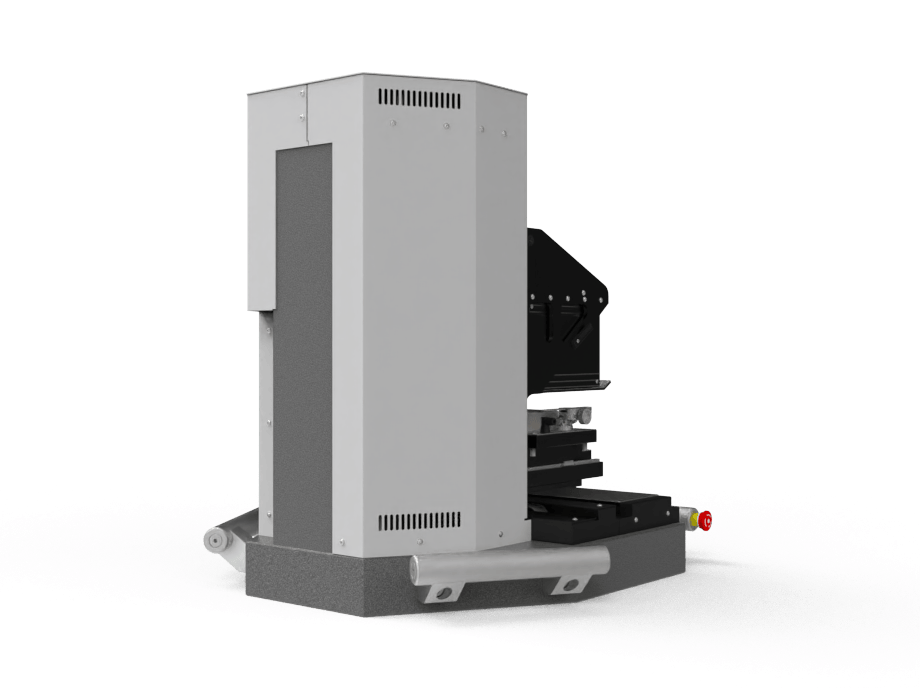

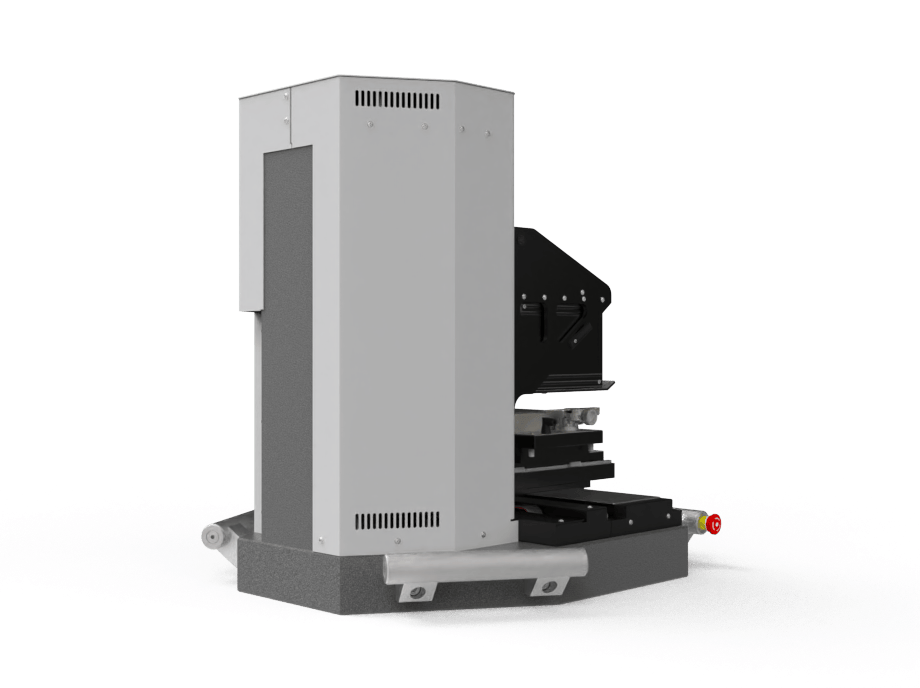

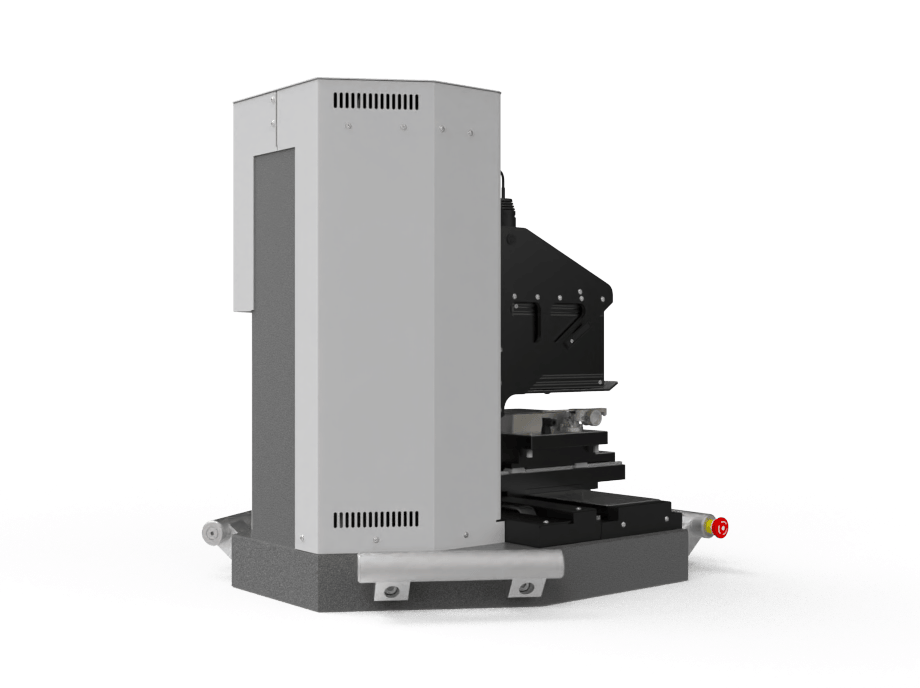

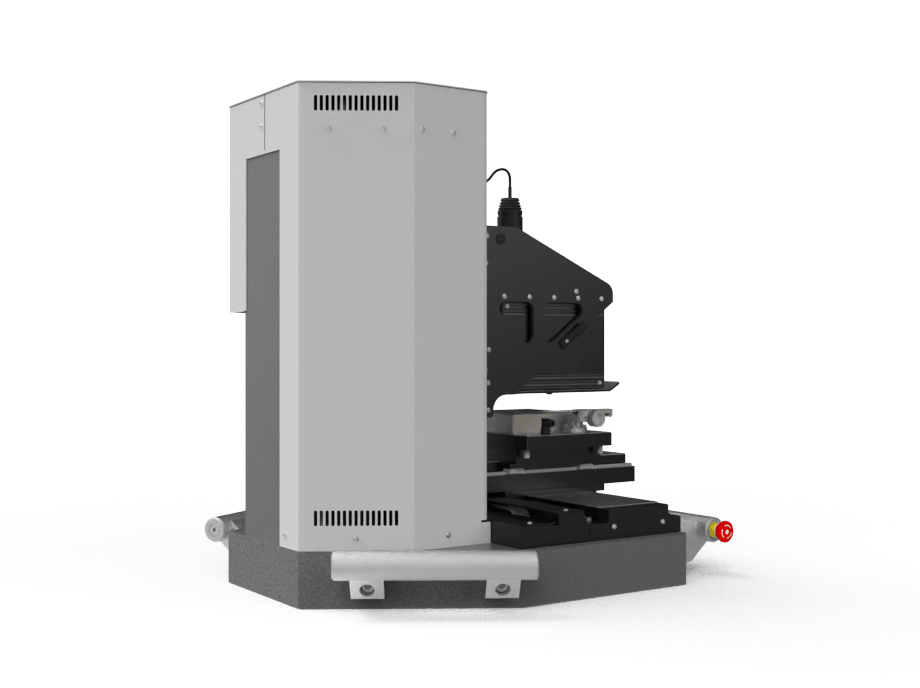

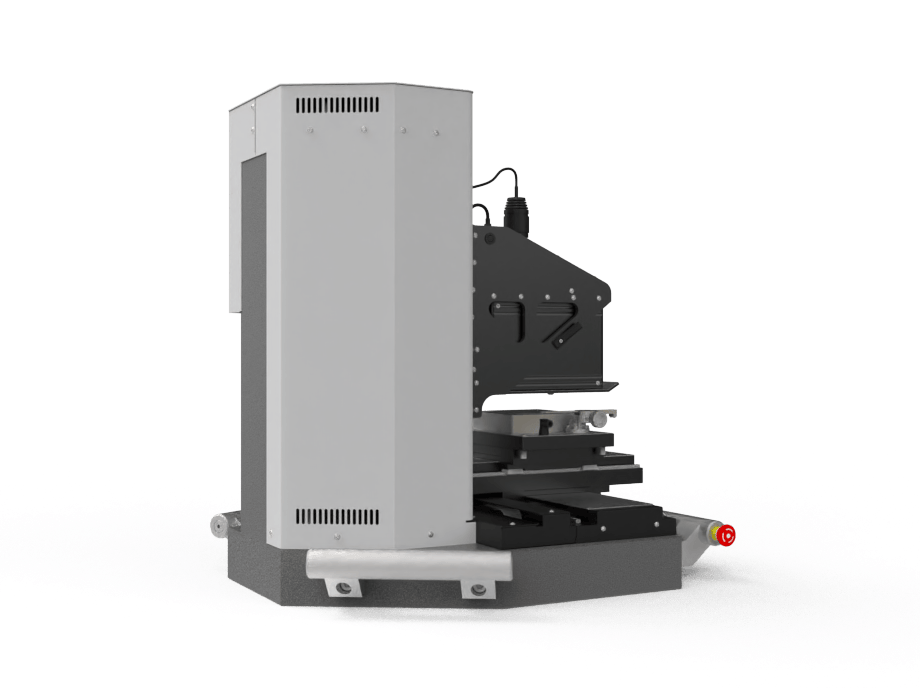

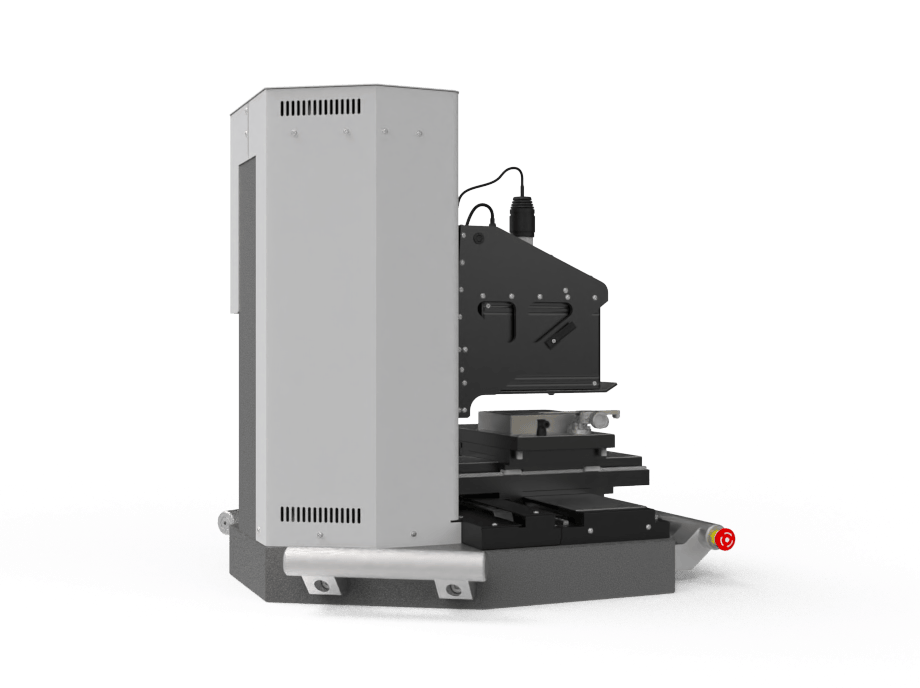

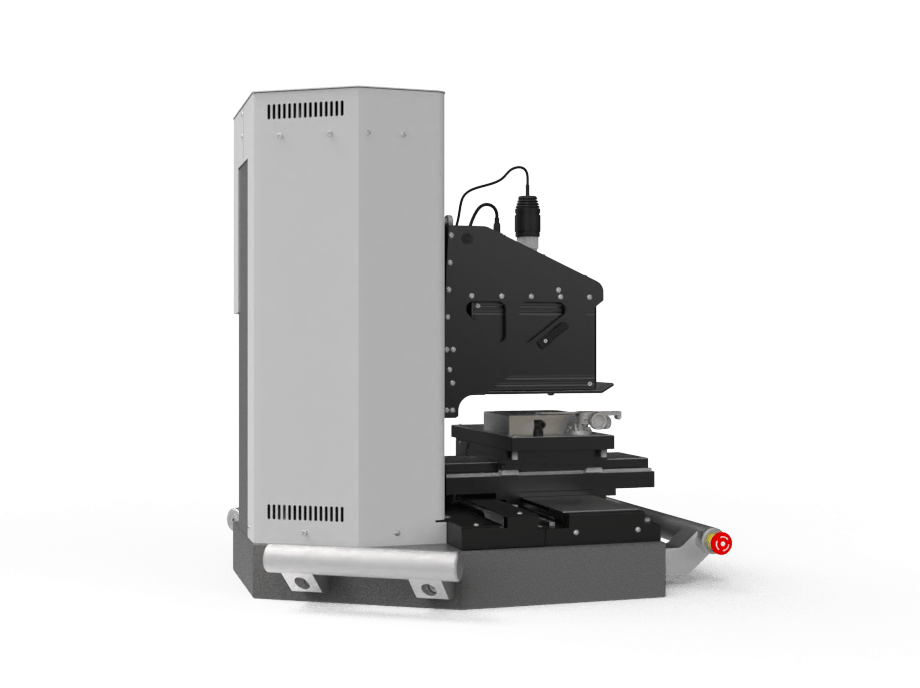

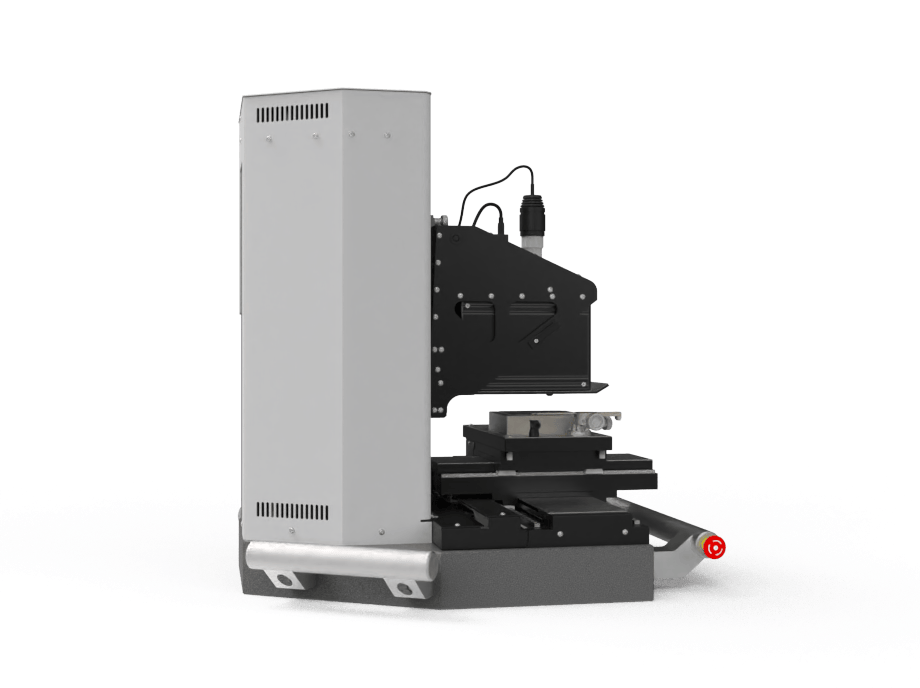

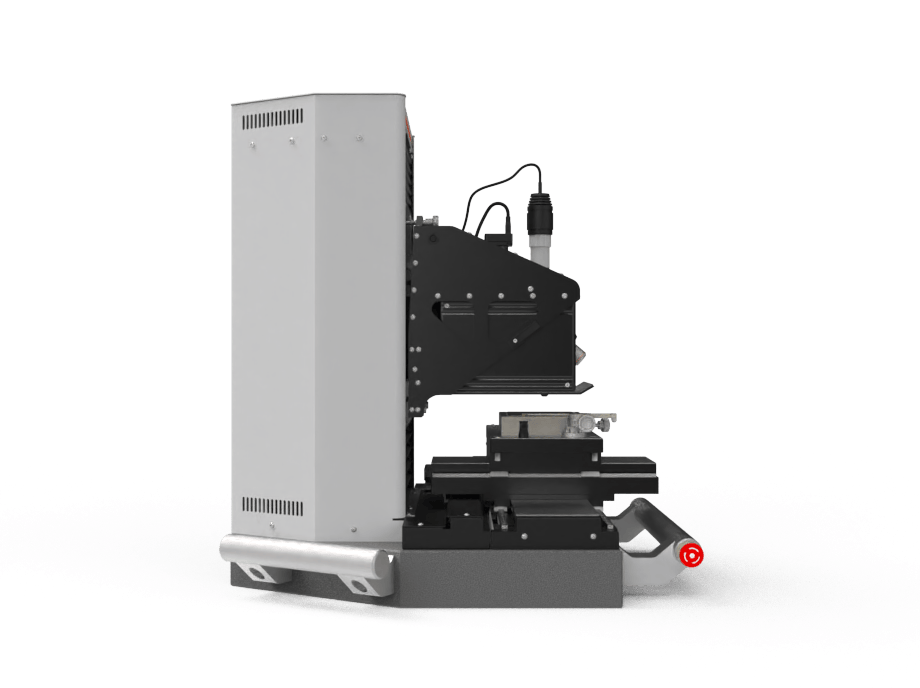

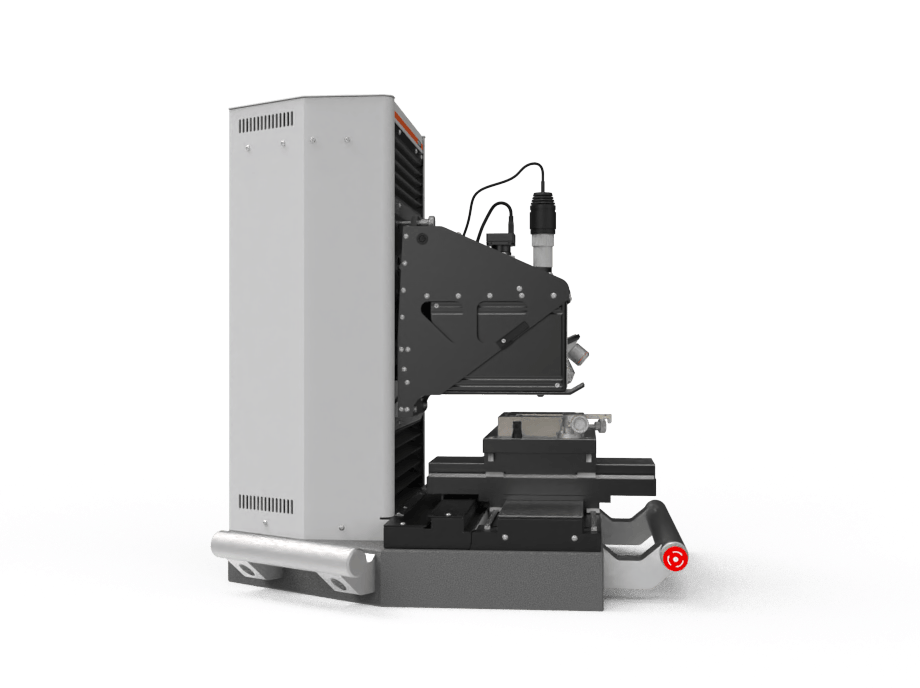

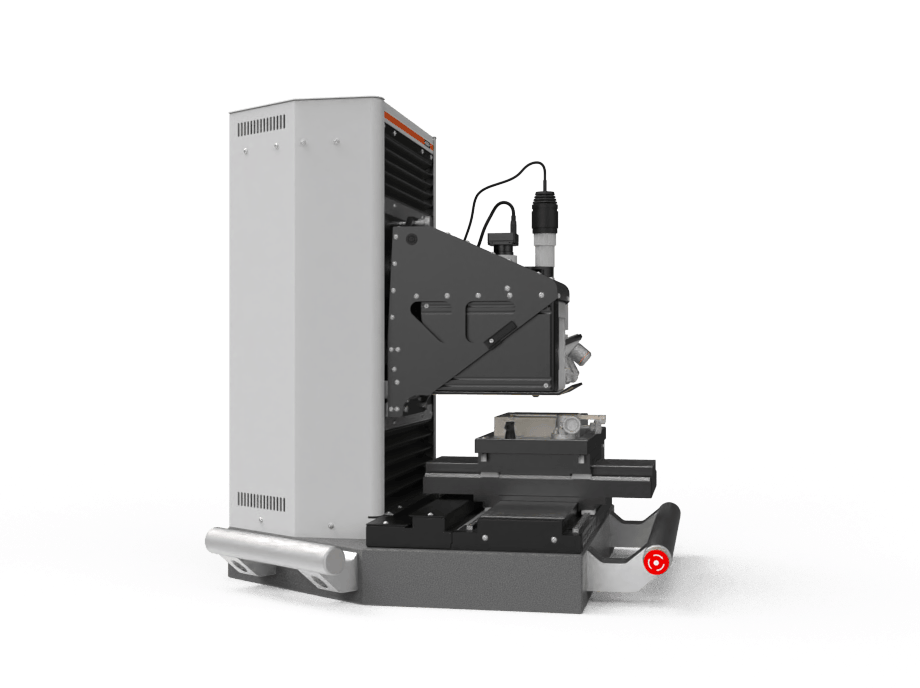

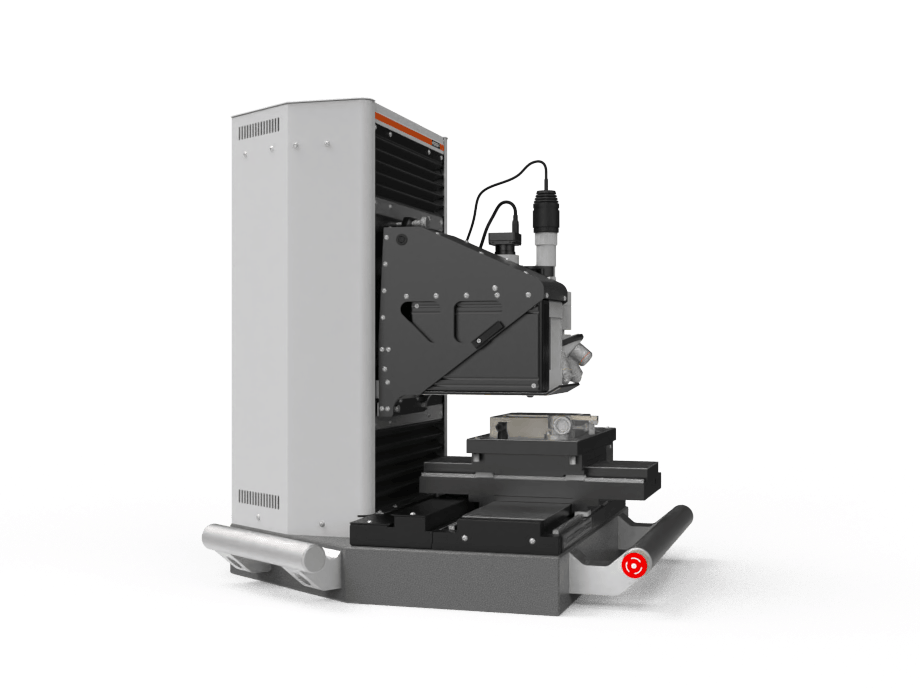

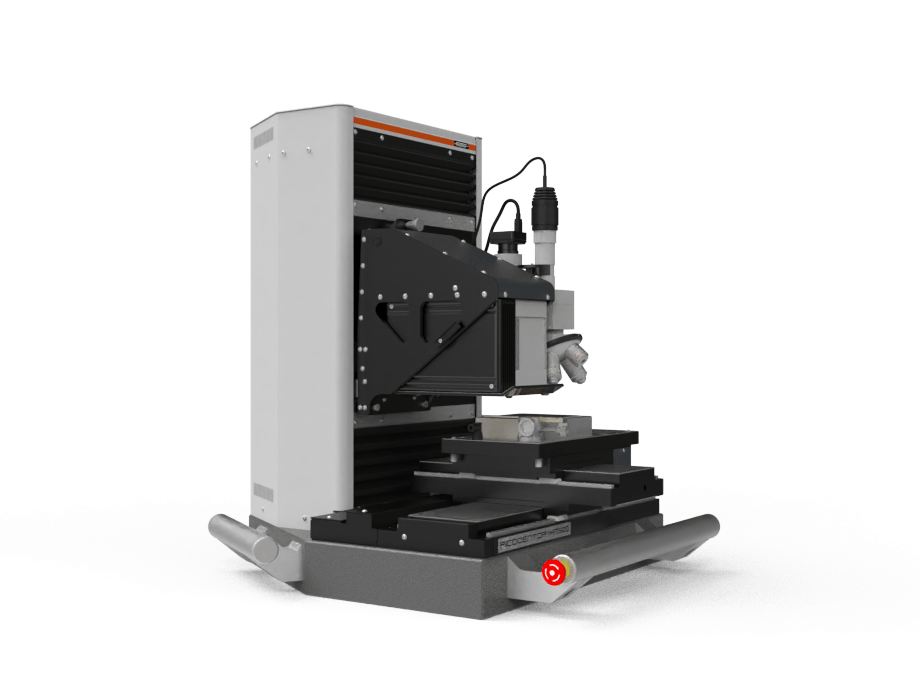

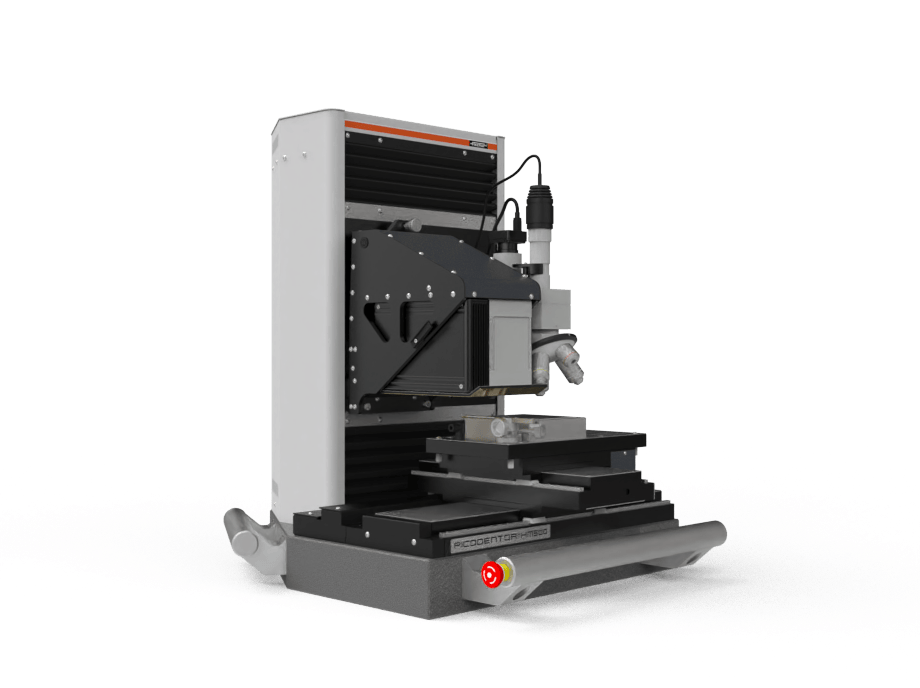

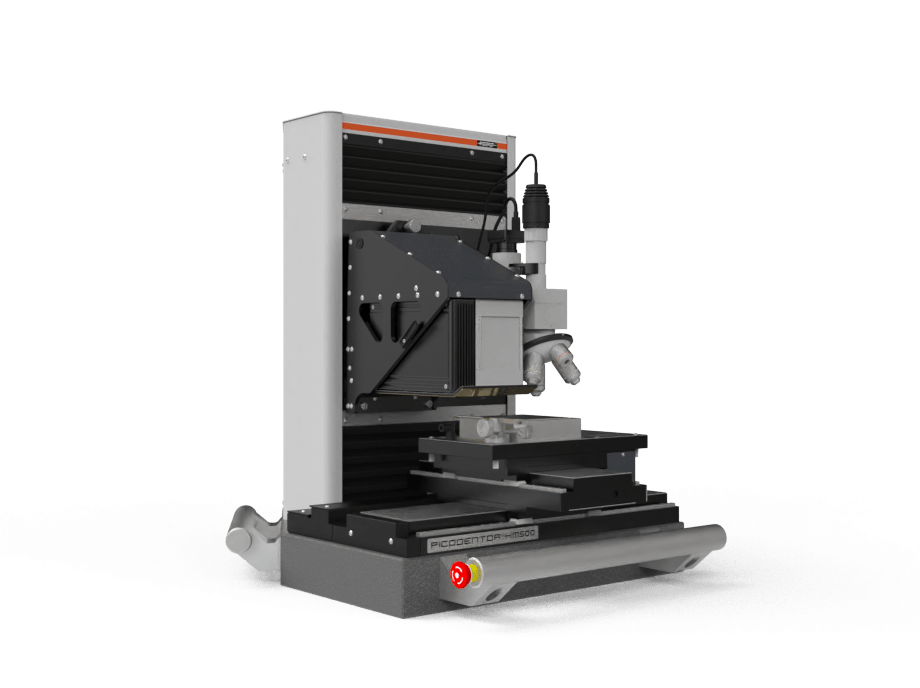

PICODENTOR® HM500

sample preparation on the market

lenses

of the sample

Automated nanoindentation for layer thicknesses smaller than 1 μm.

The PICODENTOR® HM500 combines high-end technology with easy handling. The hardness tester is designed for particularly fine instrumental indentation testing and dynamic mechanical analysis. It allows the depth-dependent determination of material quantities such as Martens or Vickers hardness and the elastic indentation modulus - and does so absolutely reliably and precisely. The measuring system impresses with a programmable measuring table, a high-intensity microscope and reduces the influence of external influences thanks to its clever design.

Easy to use.

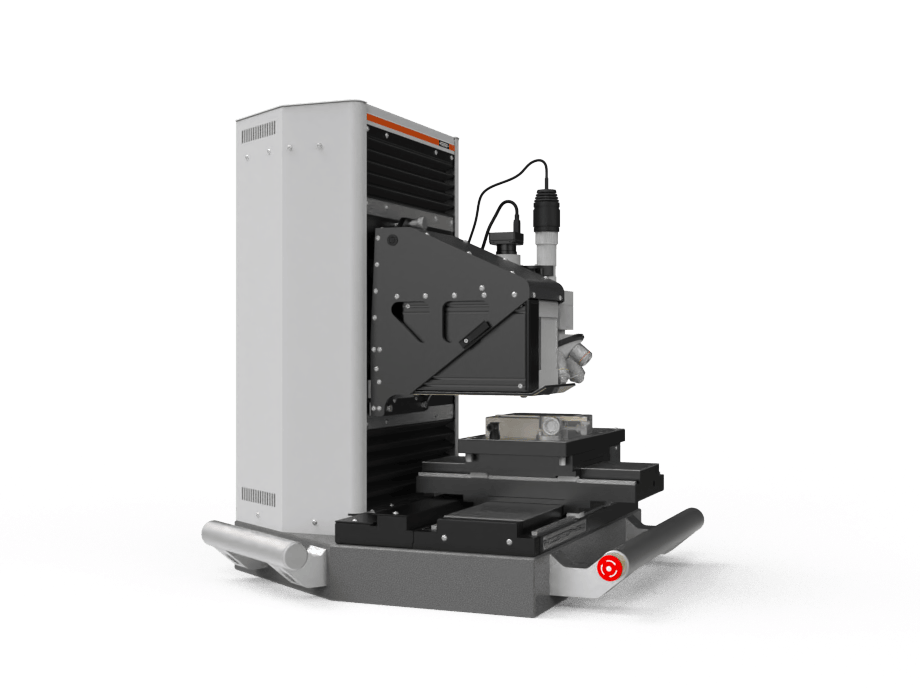

Automatic lens detection and motorized Z-axis with autofocus

Simply automated.

Serial inspections thanks to automated specimen stage and powerful microscope

Powerful application software.

Intuitive operation with WIN-HCU® software

More sensitive touchdown.

Measuring head suitable for highest requirements and very soft materials

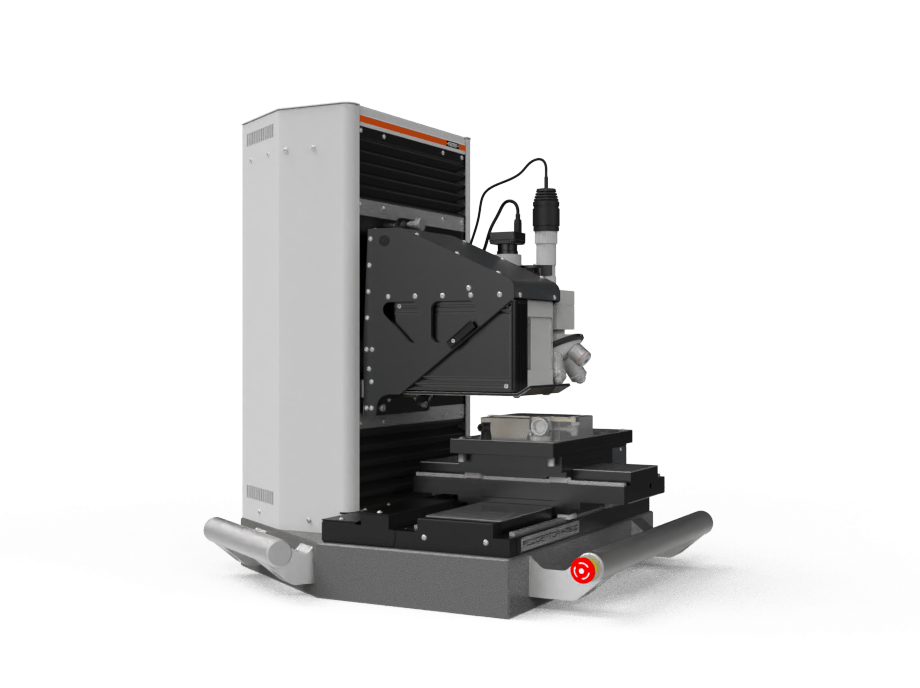

Quick-measure design.

Fast measuring without time-consuming sample preparation; ideal for laboratory and production control

Does more.

High sample throughput possible

Features

Determining plastic and elastic properties such as Vickers hardness, elastic indentation modulus and creep behavior

Measuring and calculation of parameters according to DIN EN ISO 14577 and ASTM E 2546

High quality microscope at scientific level, AFM update

Testing of solid materials and coatings in the nm range, test force range 0.005 - 500 mN

Temperature-stable and vibration-resistant: Possible measurements without external influences

Powerful WIN-HCU® software for intuitive operation and evaluation

Indentor shapes: Vickers, Berkovich, carbide ball as well as custom indentors on request

Programmable, high-precision measuring table for automated measurements

Possible sample height: Up to 13 cm

Application examples

- Hardness measurements on extremely small sample areas, such as bond pads in the semiconductor industry

- Analysis of ion-implanted surfaces

- Testing of nanolayers in sensors

- Hardness measurements on biological materials

- Dynamic mechanical analysis of small samples

- Measuring the hardness and elasticity of PVD and CVD coatings, such as DLC (Diamond Like Carbon) and electroless nickel coatings

- Automated measurements on multiple samples

- Determination of mechanical properties of microstructural components in materialography

Do you have further applications? Then contact us!

Application Notes

AN010 Hardness of complex coating systems for optical components 0.53 MB AN015 Hardness measurement of nano coatings on spectacle lenses 0.54 MB AN038 Determining the mechanical characteristics of gold coatings on conductive traces in printed circuit boards 0.57 MB AN060 Nanoindentation on intermediate layers in thin foils 0.49 MB AN090 Determination of the heat influence on plastics and coatings using the dynamic measurement mode 1.23 MBBrochures