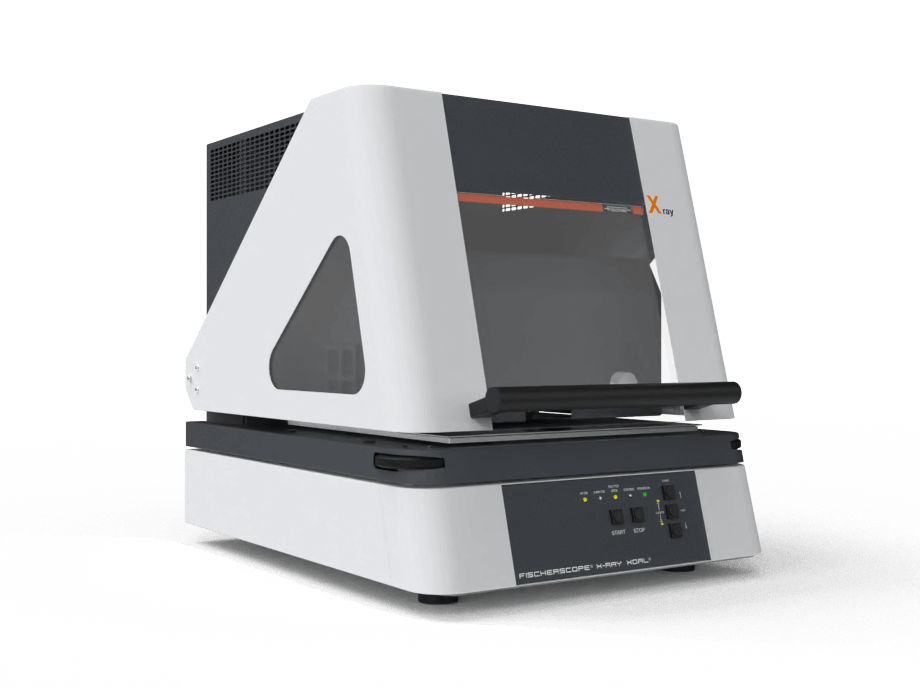

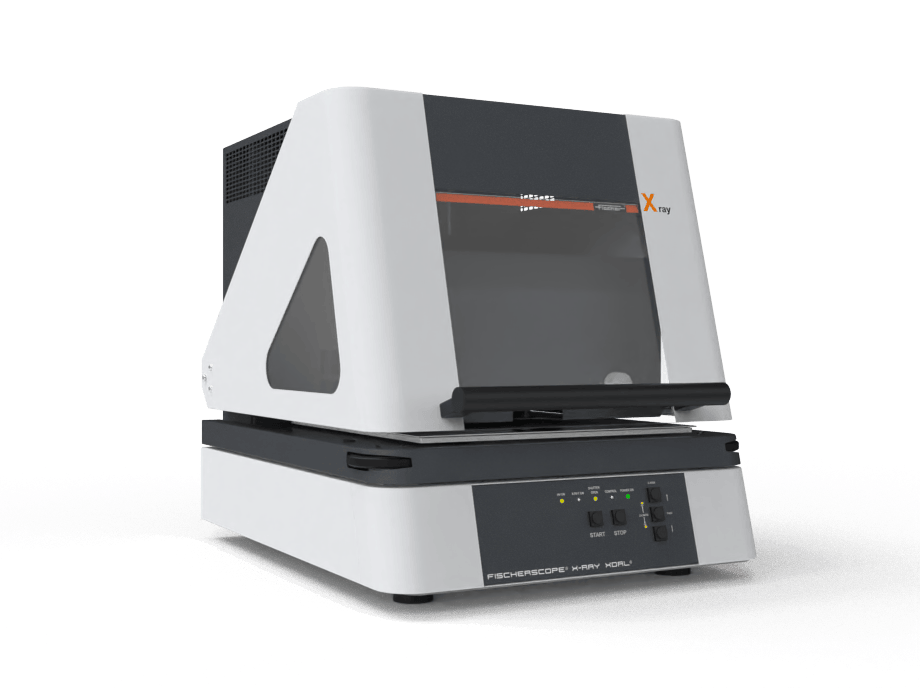

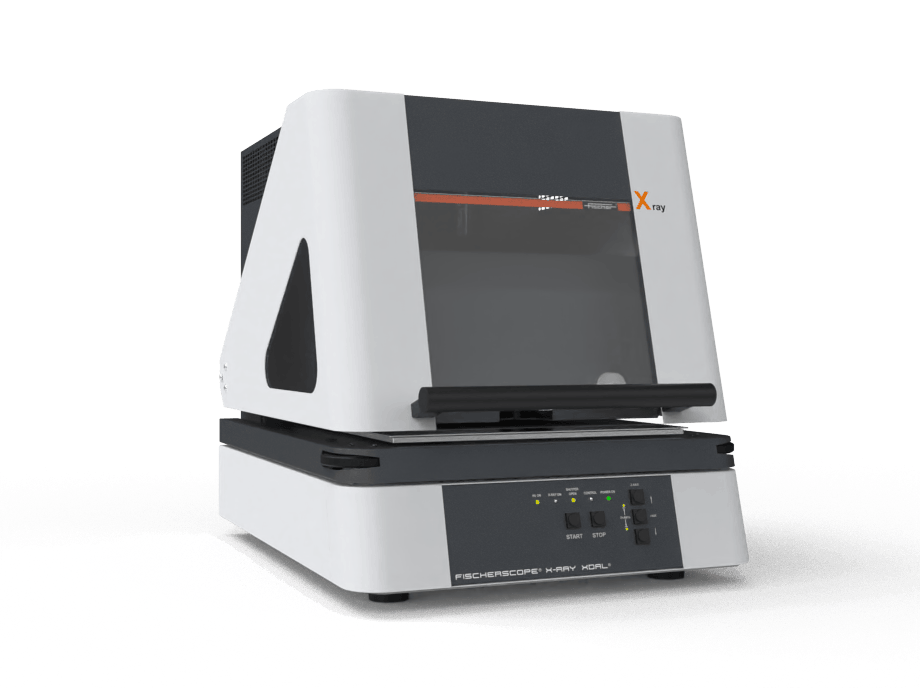

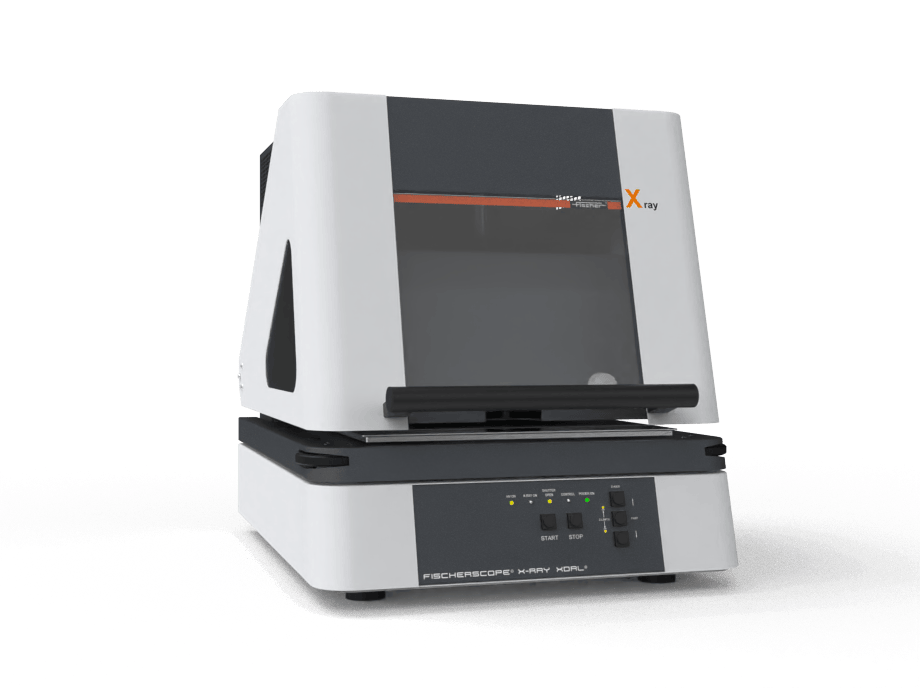

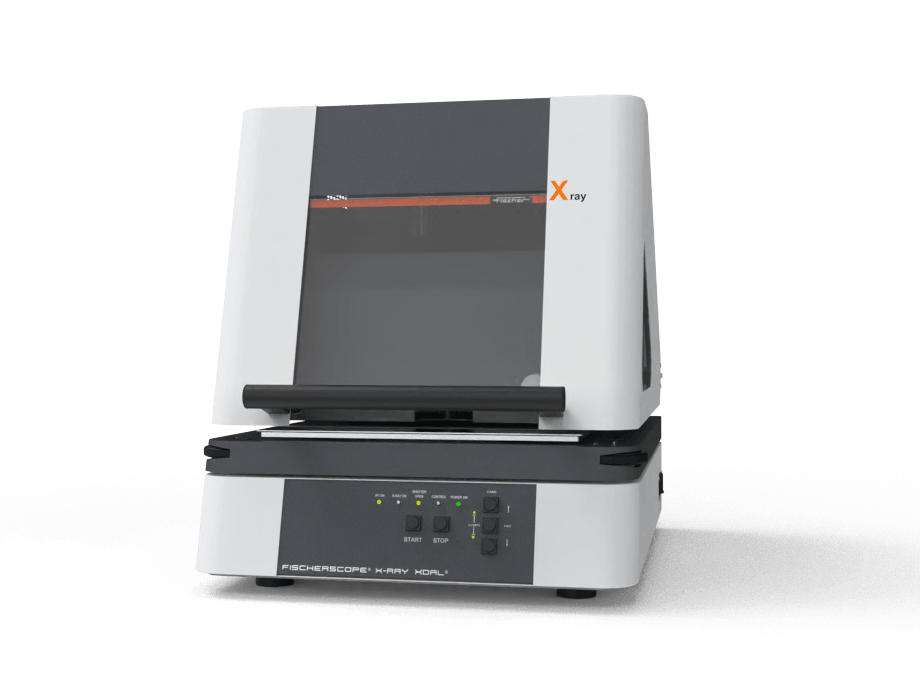

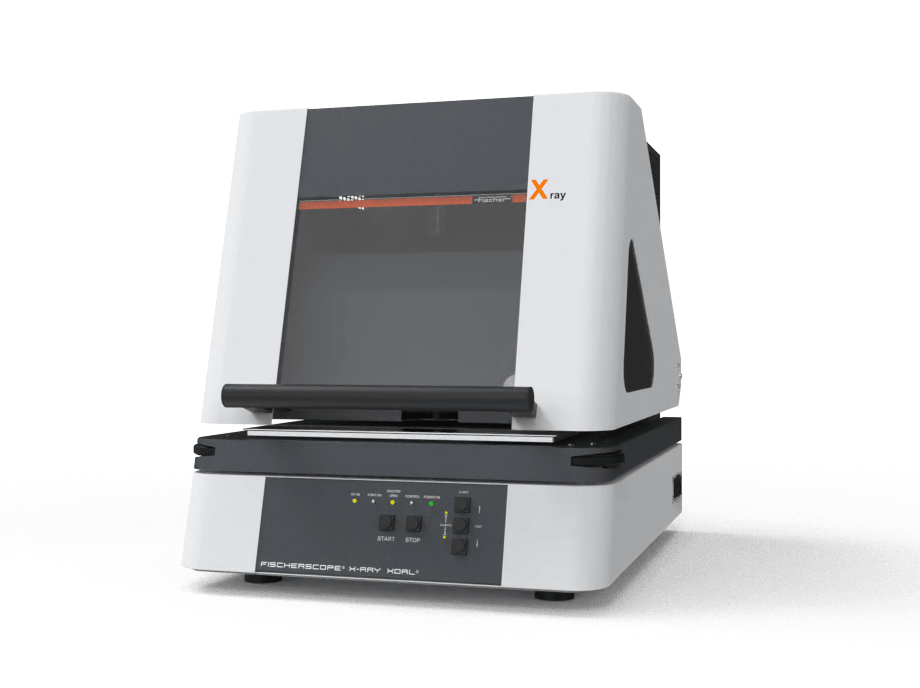

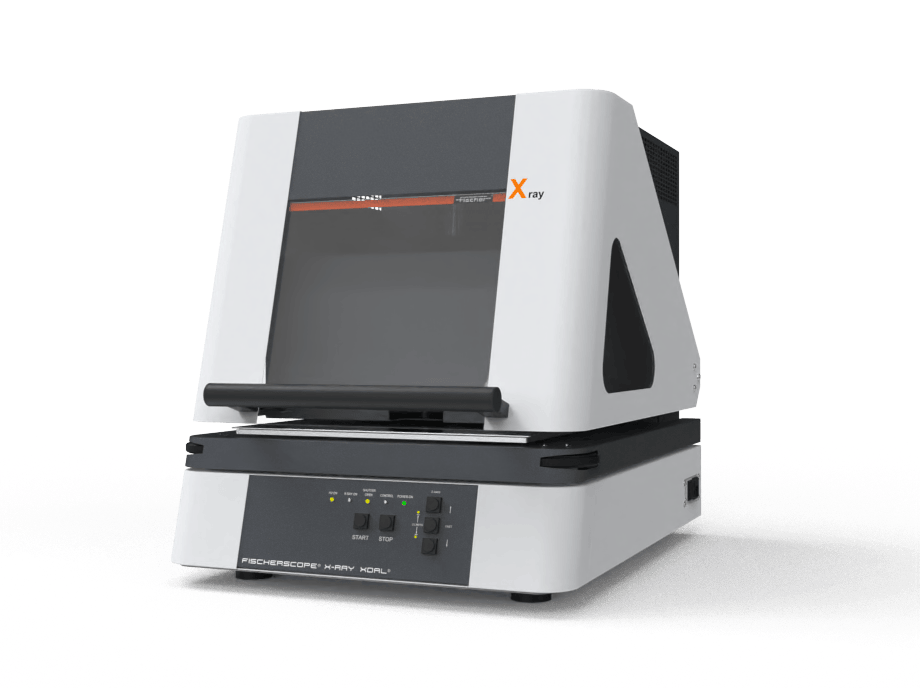

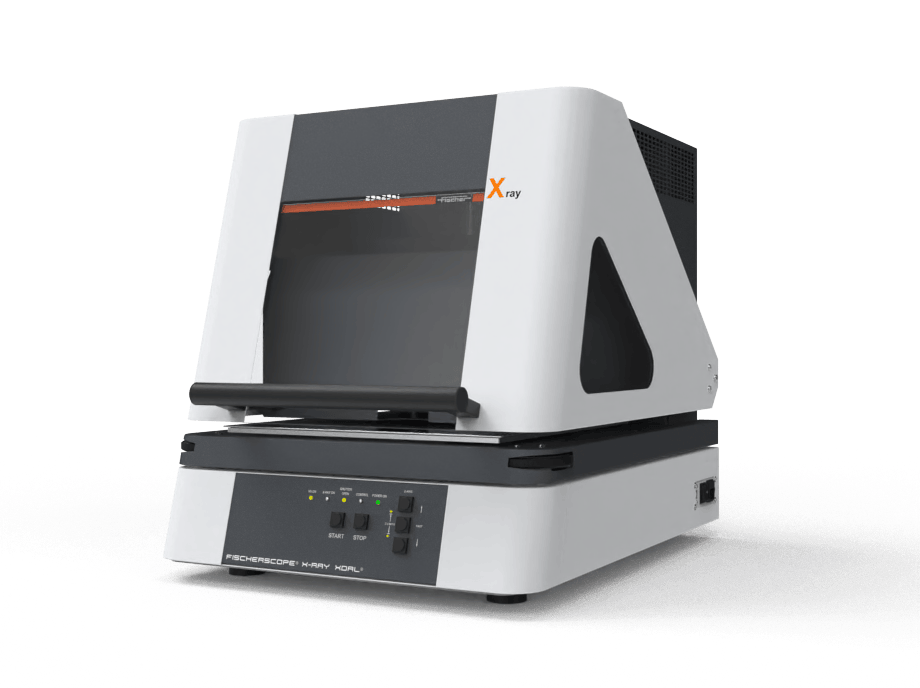

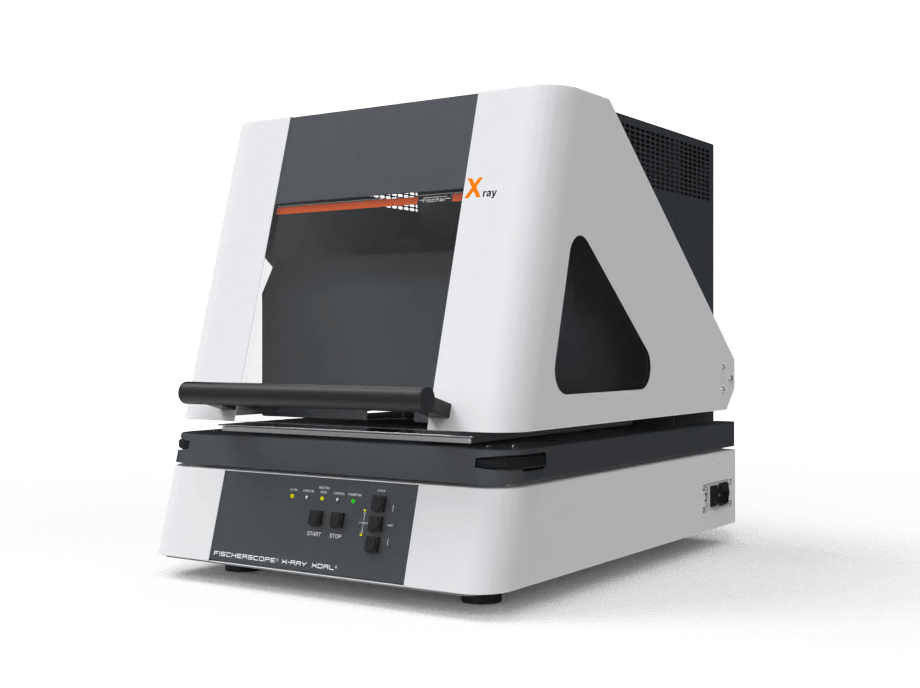

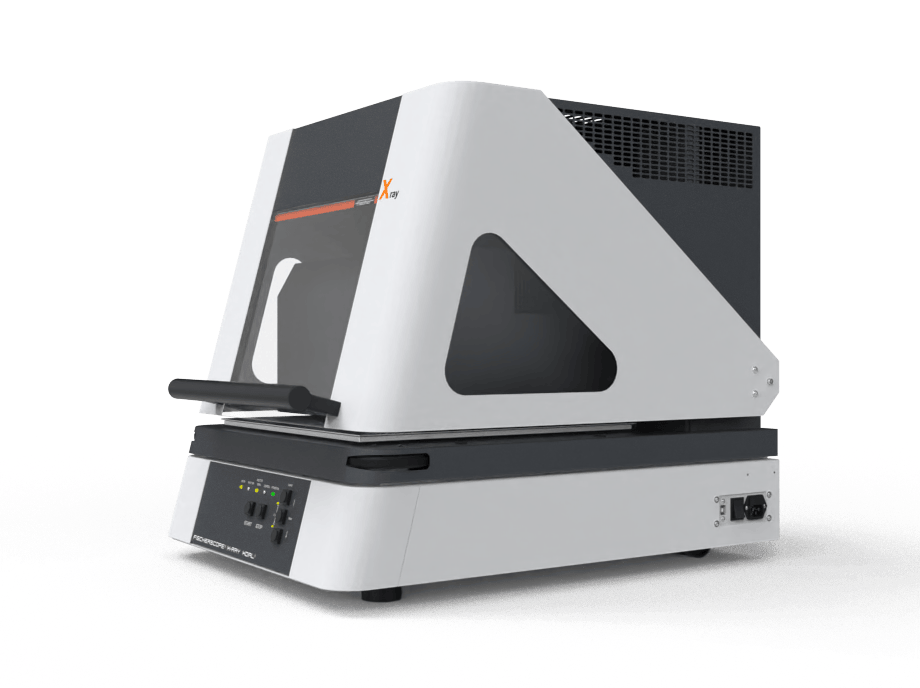

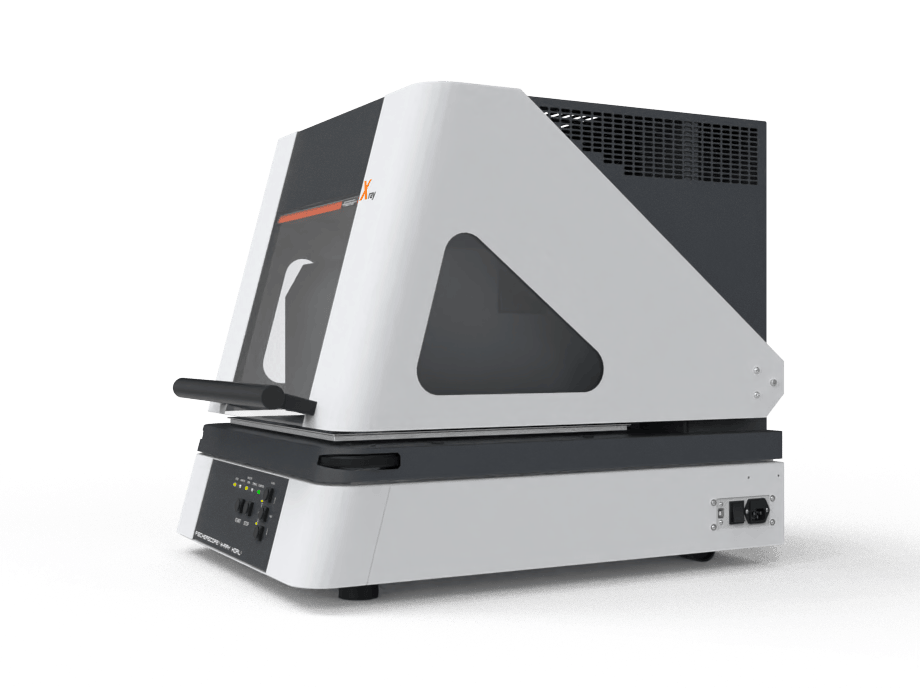

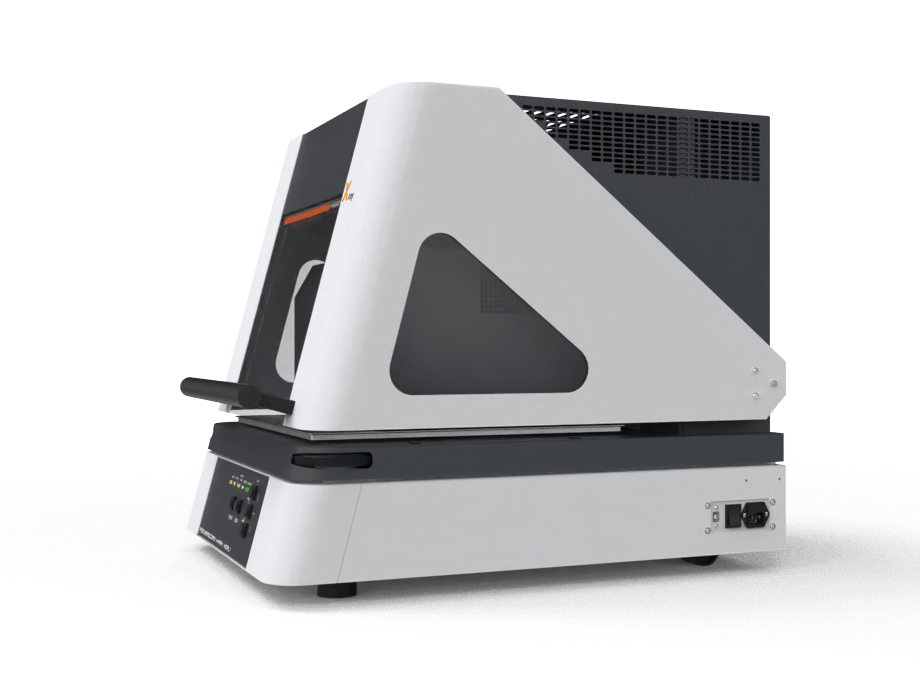

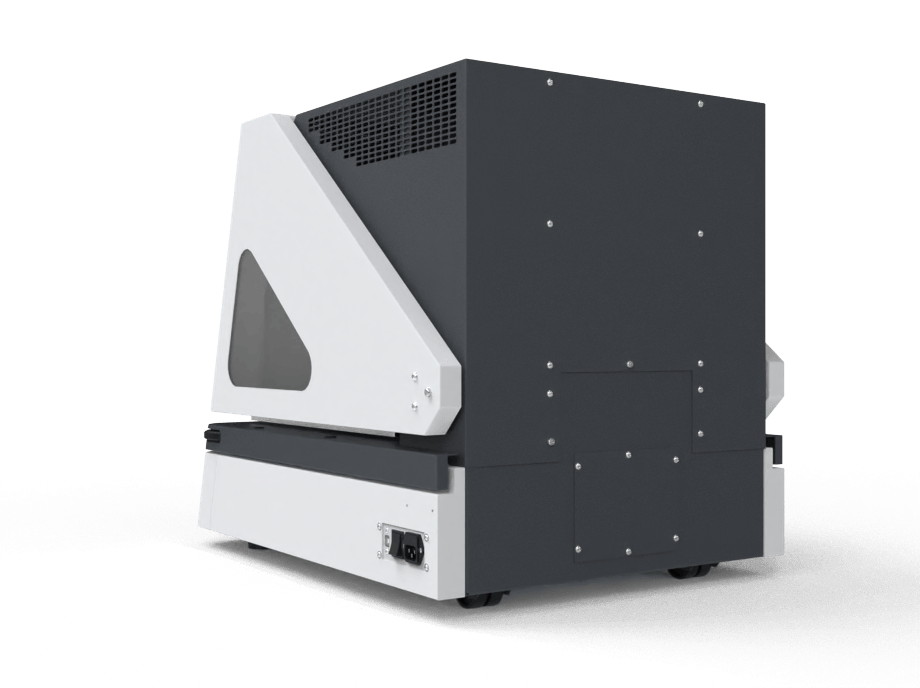

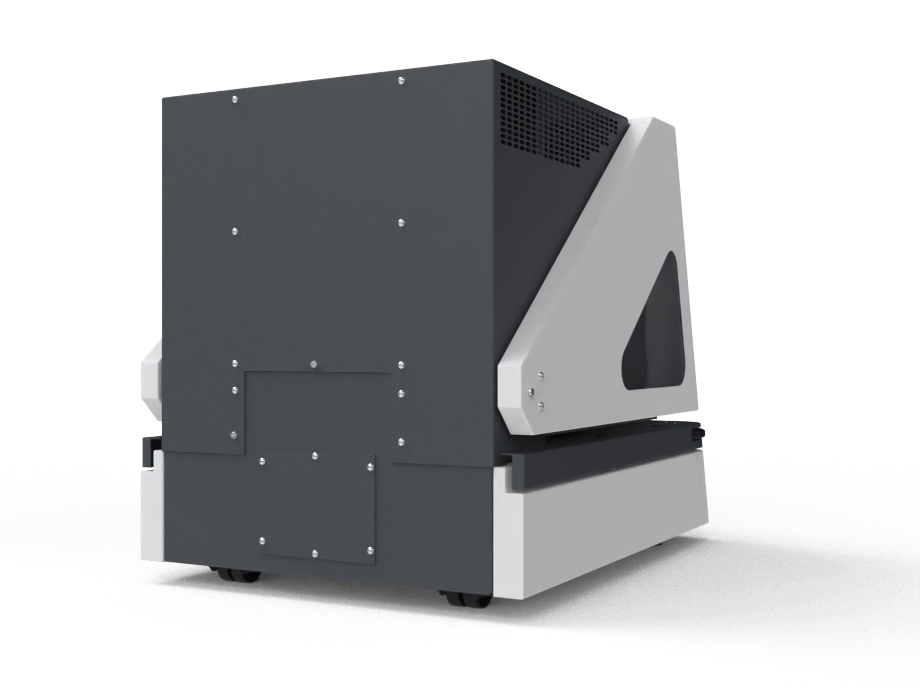

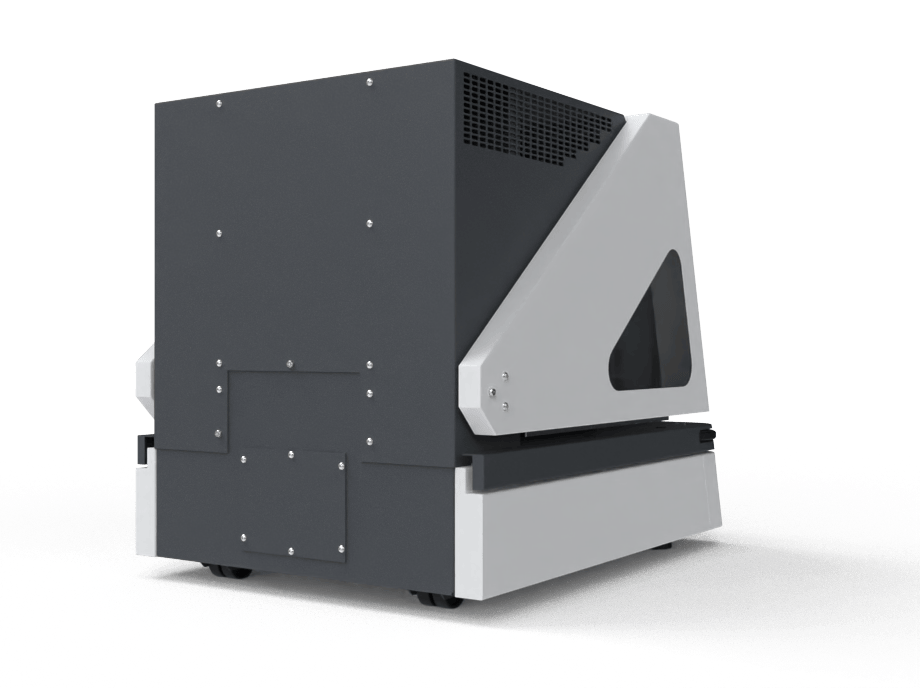

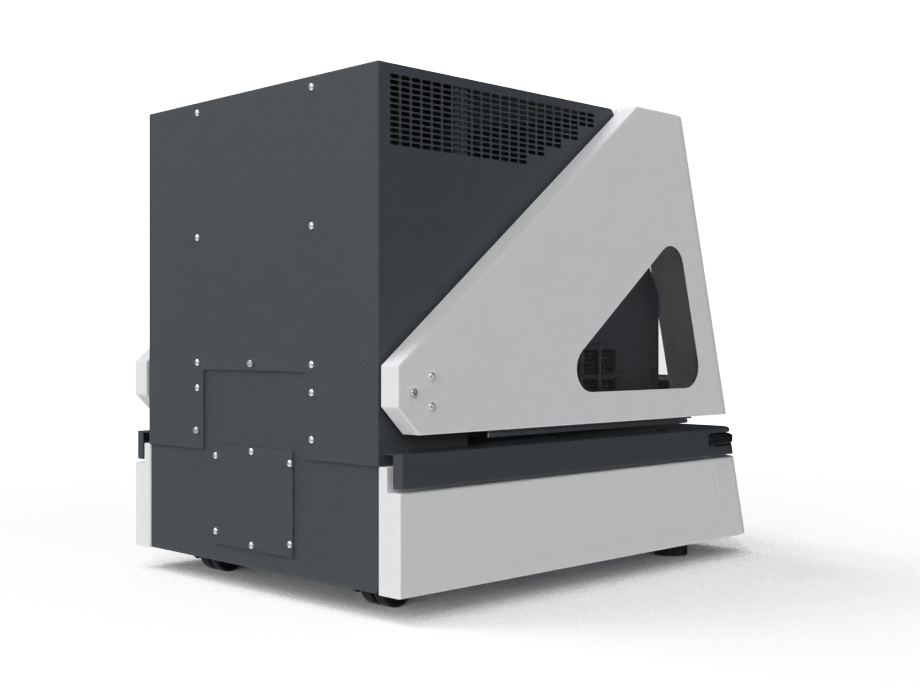

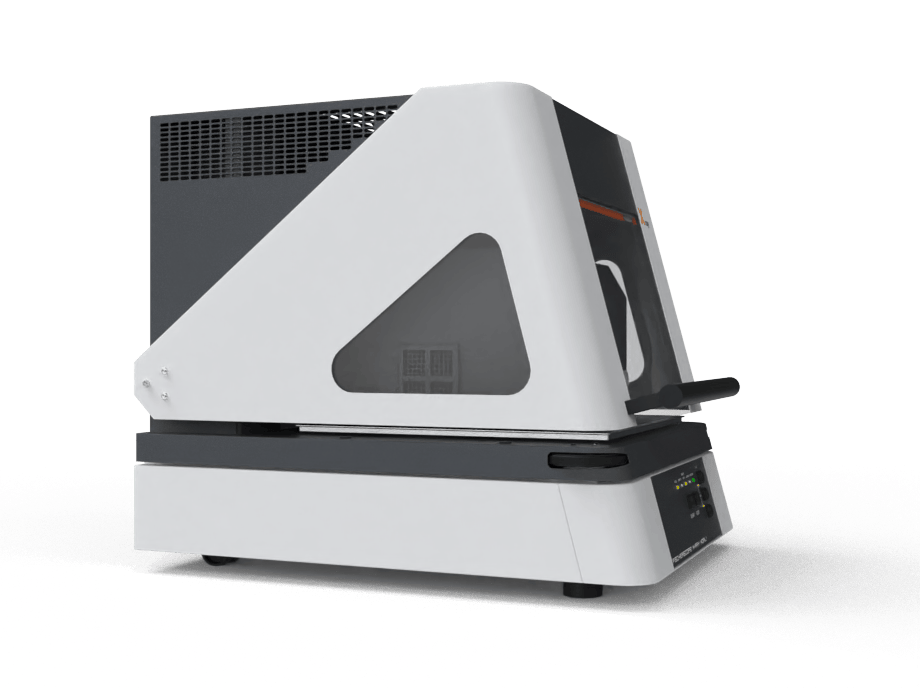

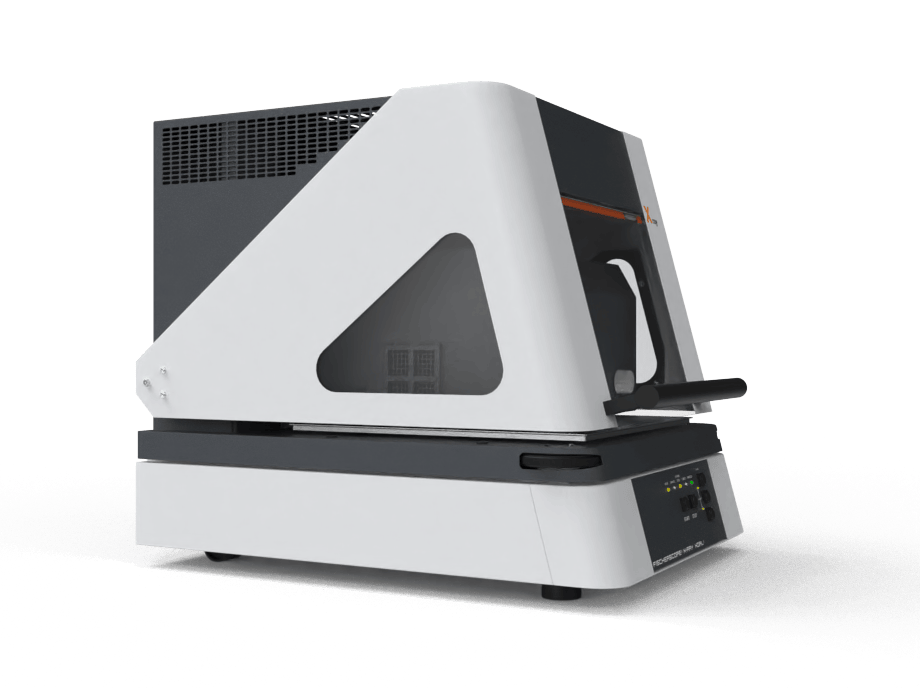

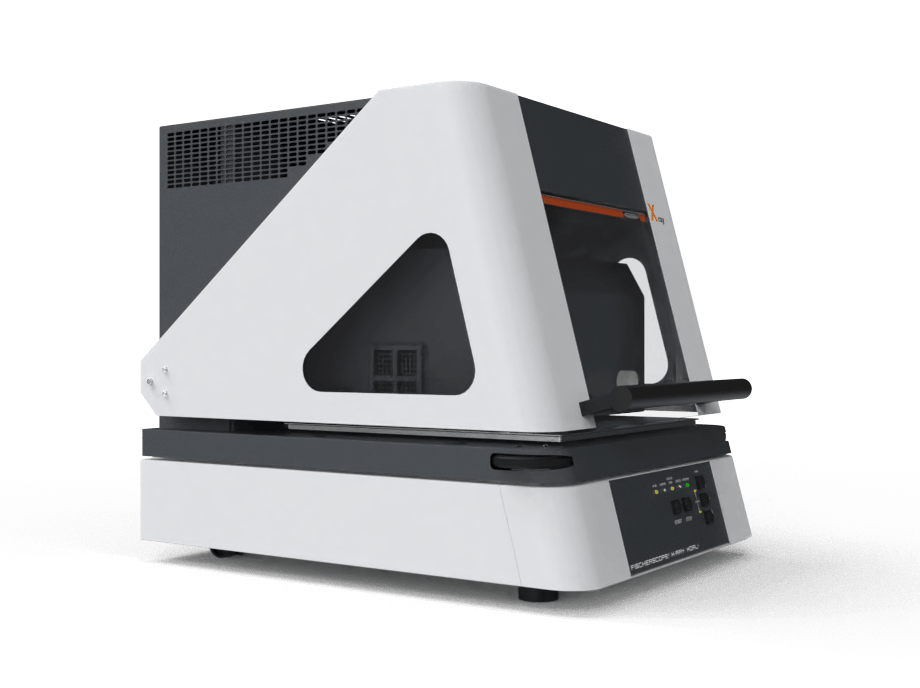

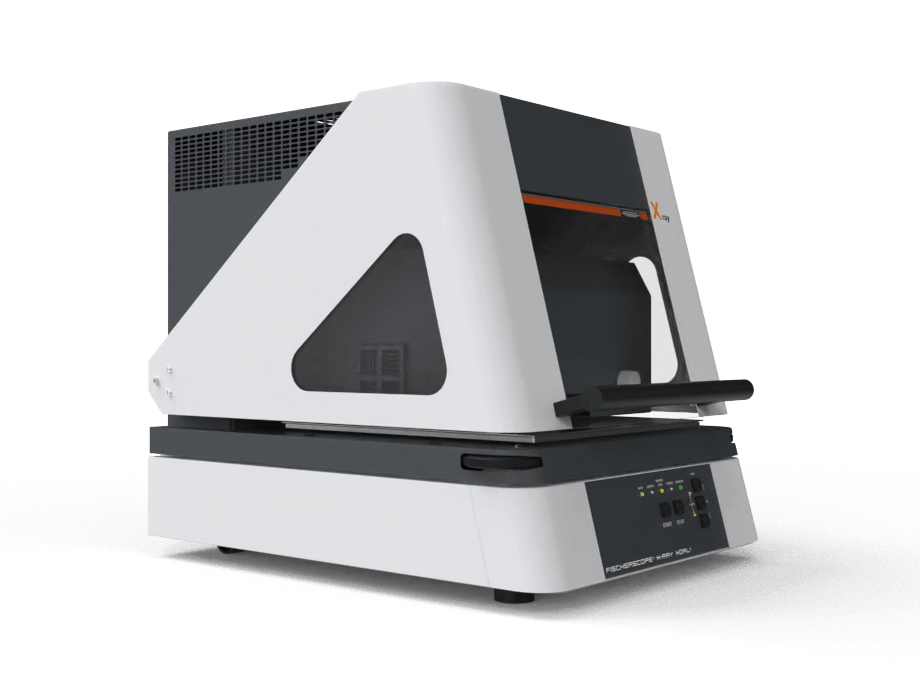

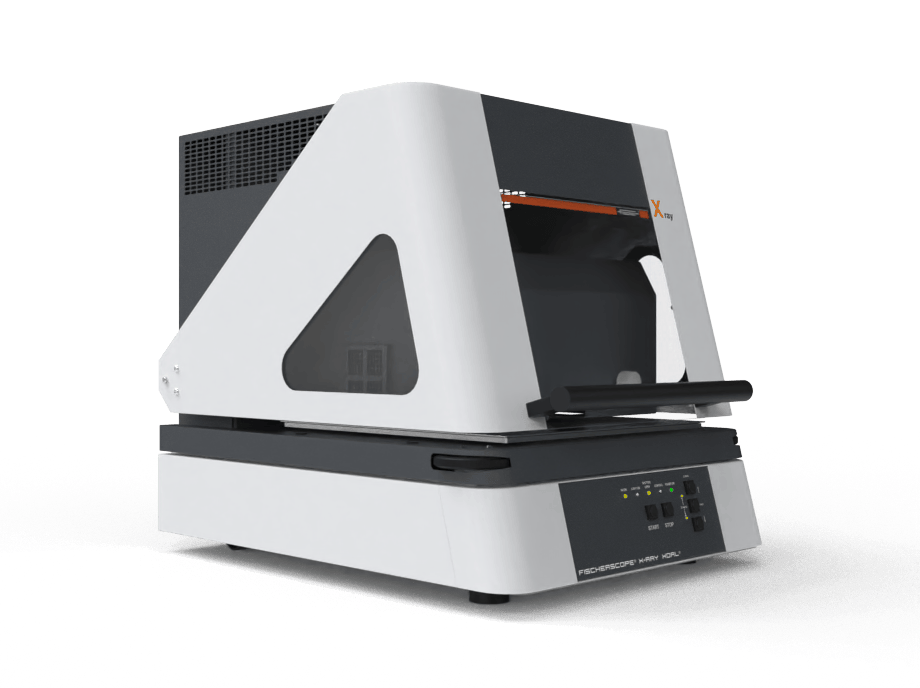

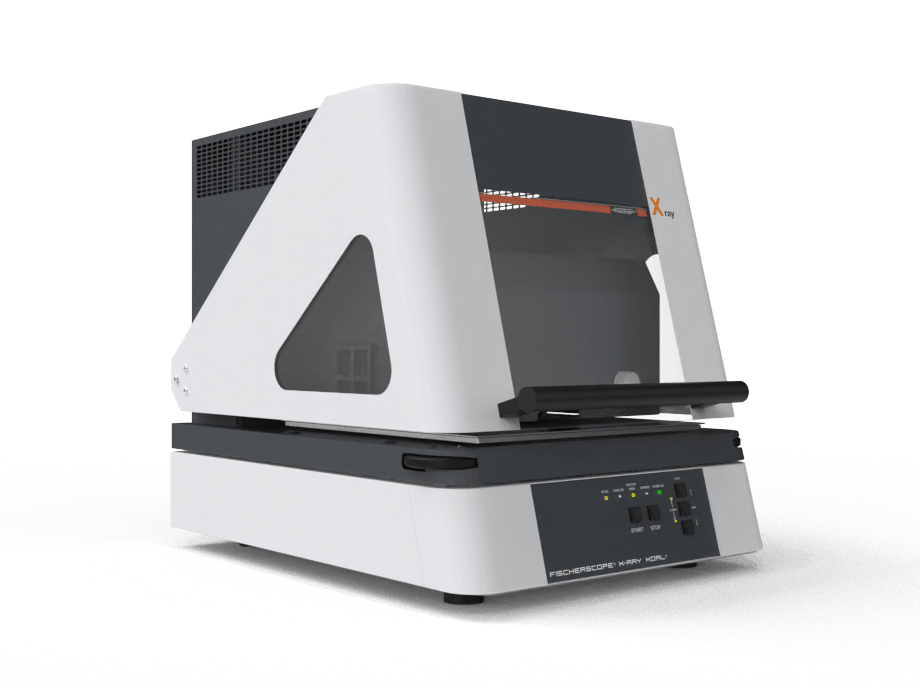

FISCHERSCOPE® X-RAY XDAL®

patented DCM method

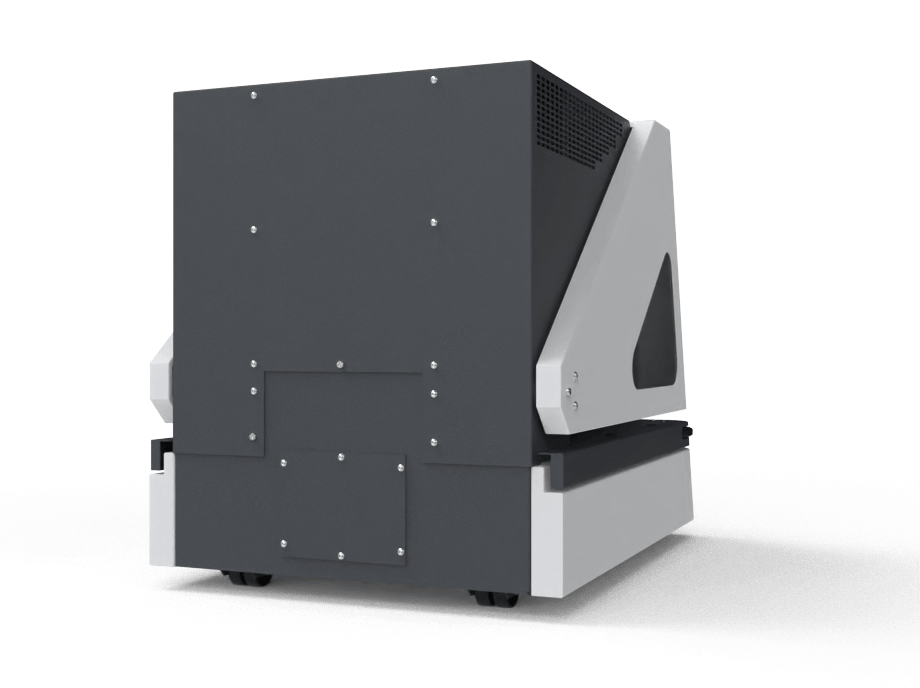

full protection device

automatable

X-ray fluorescence analysis for higher demands.

Thin, thinner, XDAL®: Thanks to the microfocus tube and various semiconductor detectors, the FISCHERSCOPE® X-RAY XDAL® series is ideal for applications in the field of thin and very thin coatings < 0.05 μm as well as for material analysis in the ppm range. The instrument version with the 50 mm² silicon drift detector is furthermore suitable for RoHS measuring. The flexible and, thanks to various configuration options (table, aperture, filter and detector), universal XDAL® measures reliably, precisely and stands for 100 % safety.

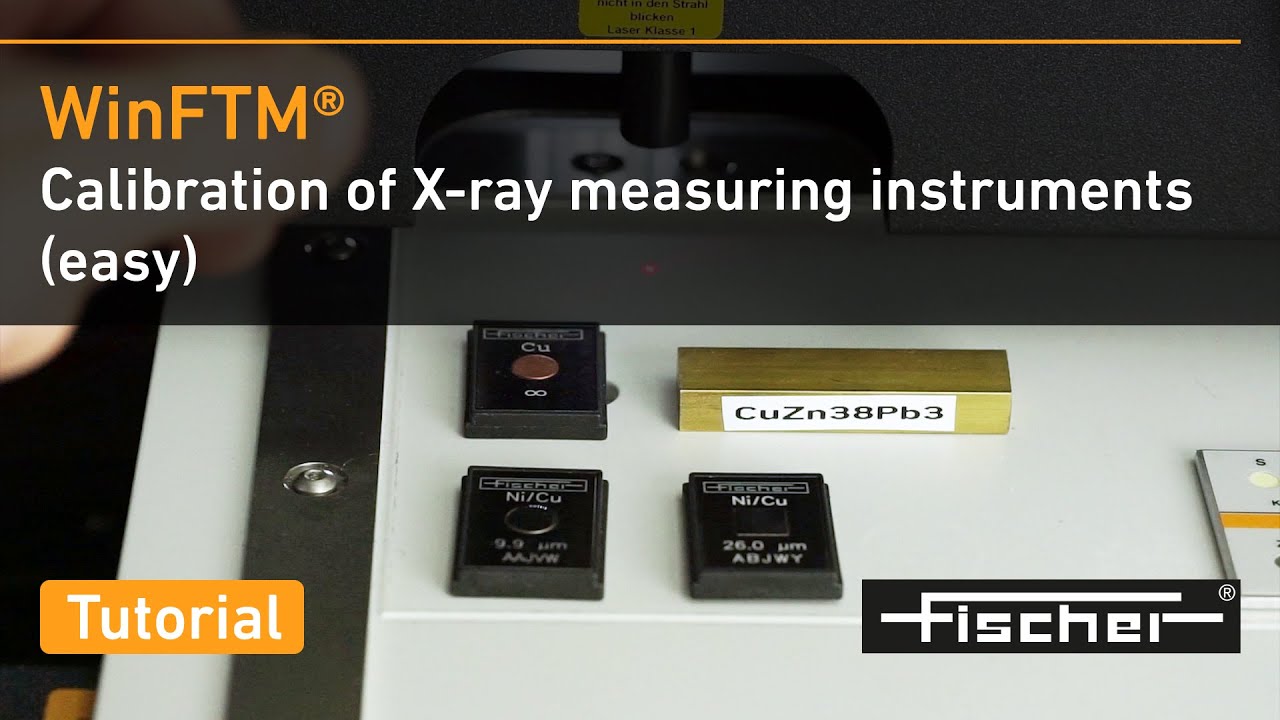

Commissioning.

Extremely fast and simple

One device, many possibilities.

Coating thickness measurement, material analysis and trace analysis

Testing of multiple measuring points.

Even with large samples, measuring points are possible on the entire sample surface

Also for large samples.

Hood with C-slot

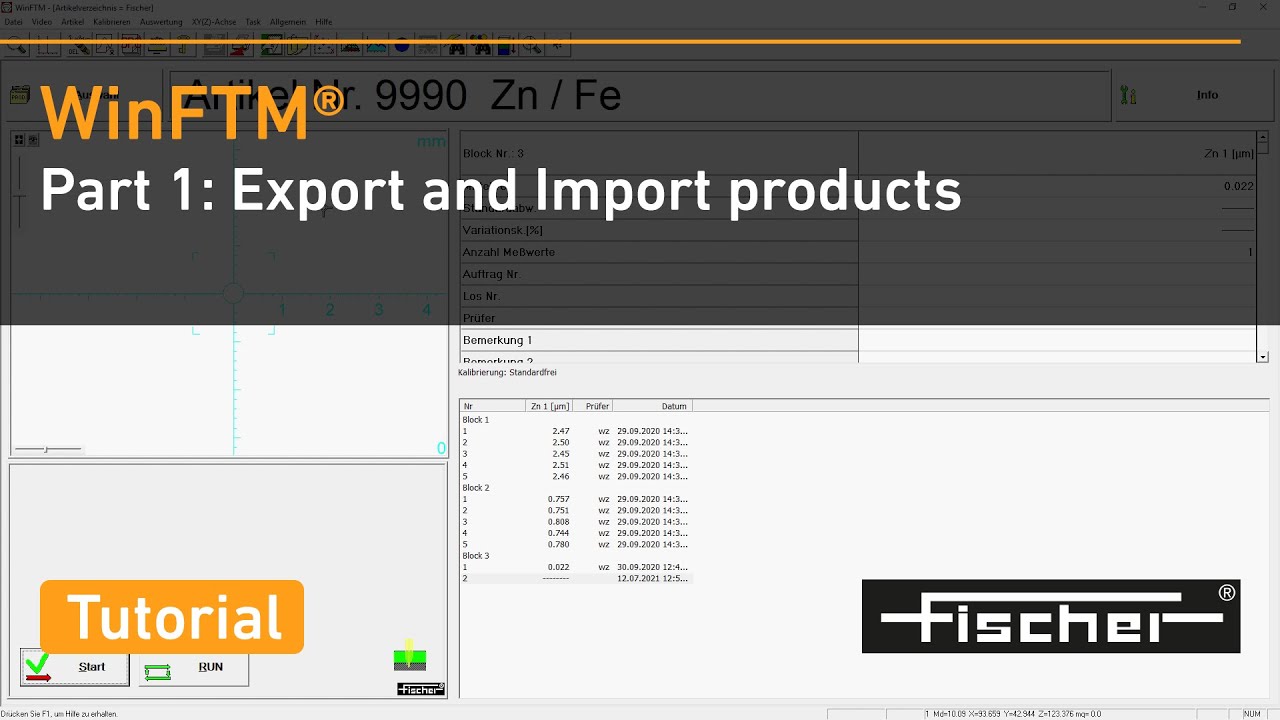

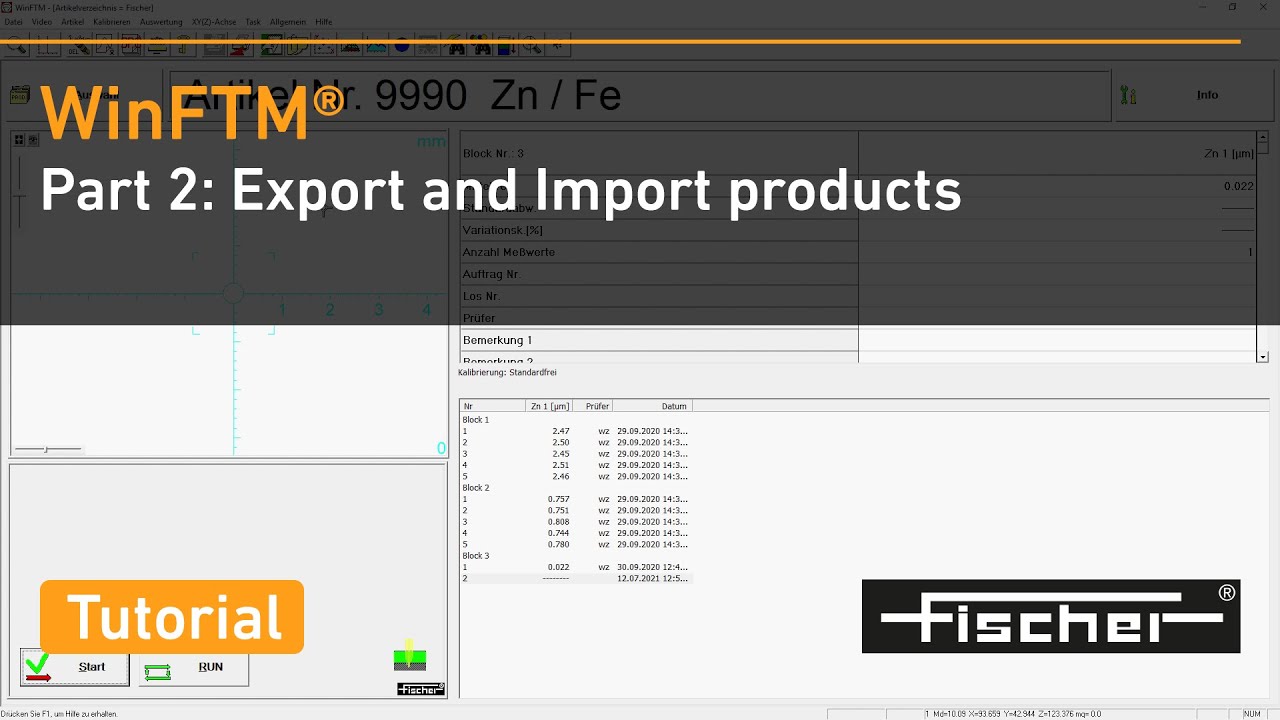

Fully automatable.

Let your instrument work for you with just one click

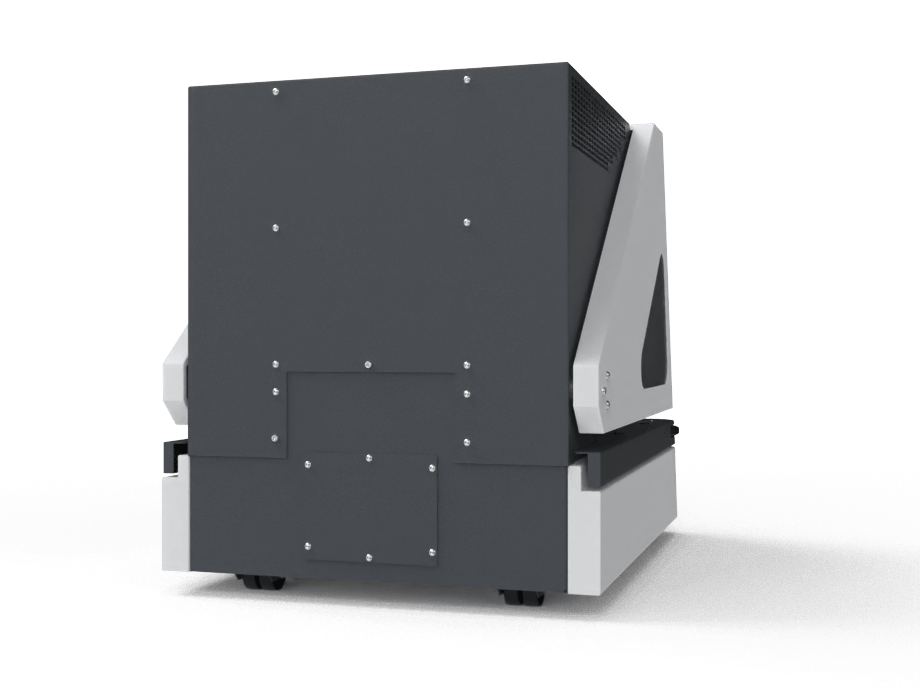

Compact design.

Very good compromise between performance and space requirements

Features

Microfocus tube with tungsten anode

Measuring spot approx.: Ø 0.15 mm

Silicon PIN and silicon drift detector for very good detection accuracy and high resolution

3-fold changeable filters

Type approved full protection device

Determination of metal content in electroplating baths with corresponding accessories

4-fold changeable apertures

Up to 140 mm possible heights of samples

Various measuring table options

Application examples

- Analysis of thin and very thin coatings of ≤ 0.05 μm

- Measuring functional coatings in the electronics and semiconductor industry, such as on lead frames, plug contacts or PCBs

- Determination of complex multilayer systems

- Automated measurements, such as in quality control

- Determination of lead content in solders

- With version SDD (20 mm² or 50 mm²):

- Determination of phosphorus content in NiP layers

- Meets ENIG/ENEPIG requirements

Do you have further applications? Then contact us!

Application Notes

AN001 Au/Pd coatings in the nm range on printed circuit boards 0.48 MB AN068 Determination of Pb in solder alloys for high reliability applications 0.67 MB AN081 Analysing cemented carbide alloys used for making cutting tools 0.50 MB AN092 How to choose an XRF instrument 1.29 MB AN093 XRF analysis for non-destructive coating thickness measurement in the field of cold forging 0.75 MBProduct videos

Tutorials

Webinars

Brochures

Technical articles