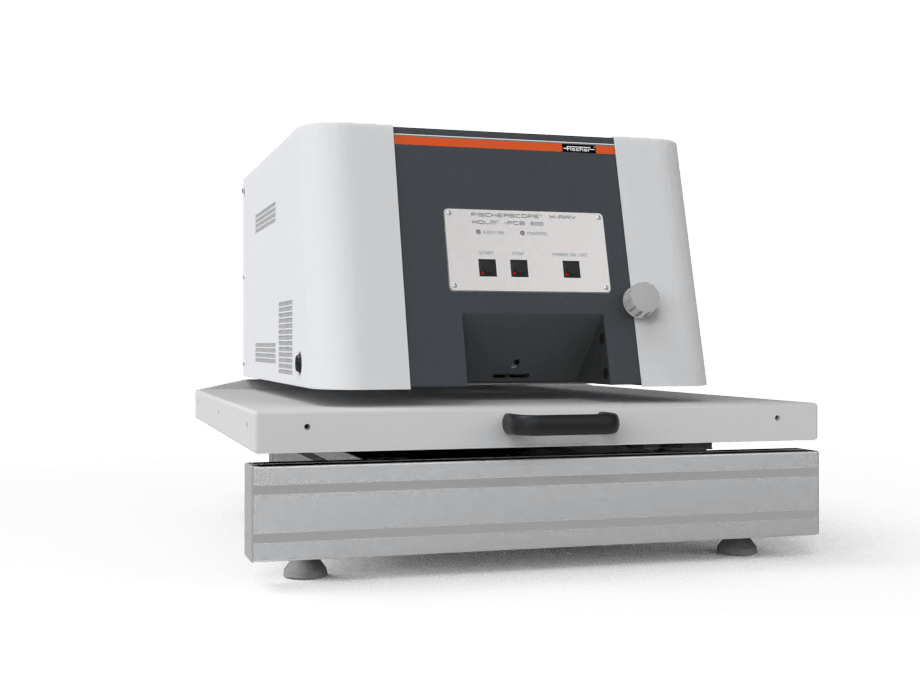

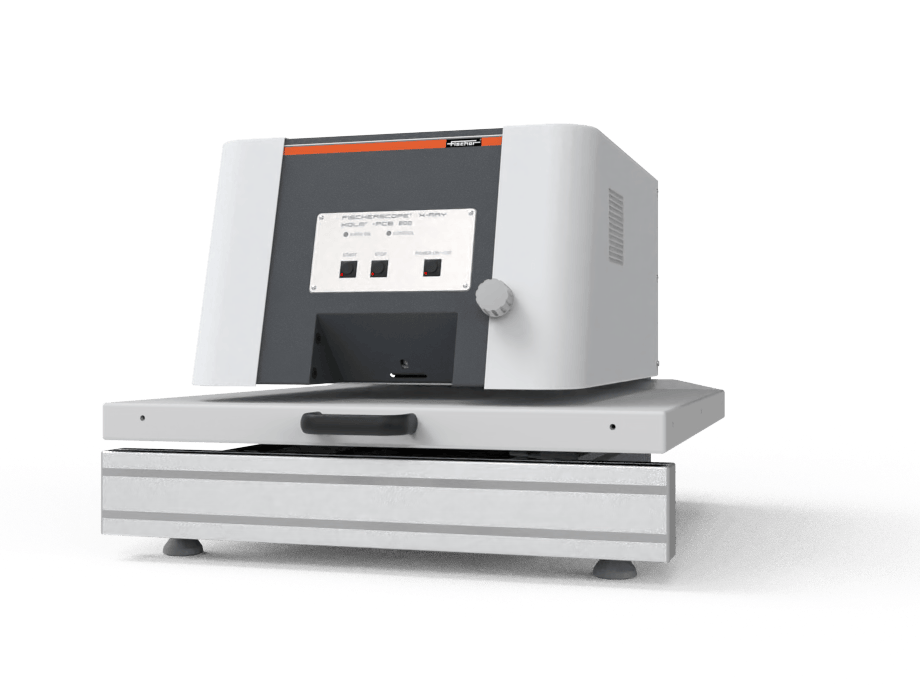

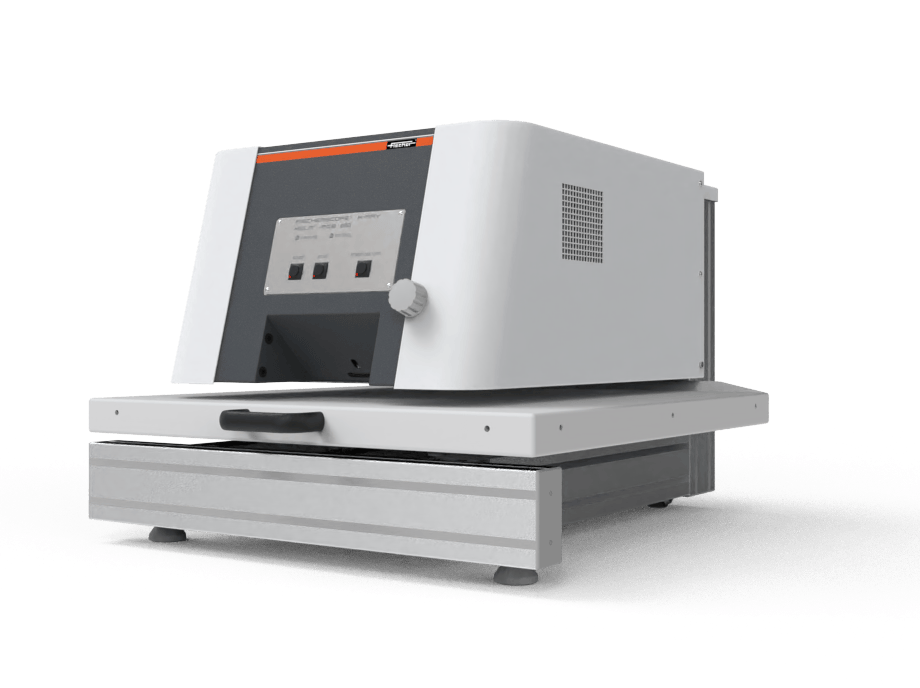

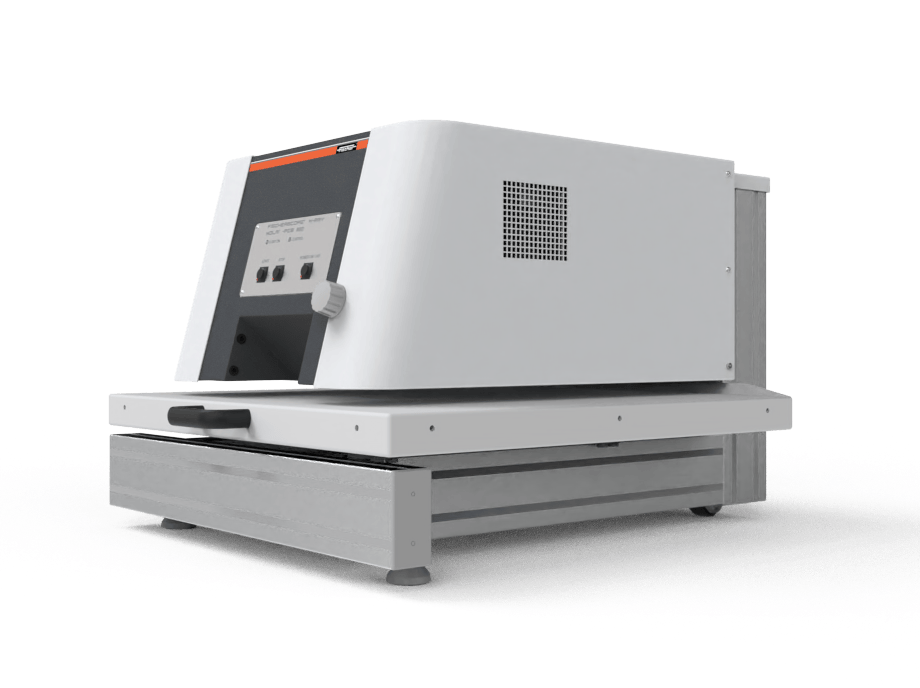

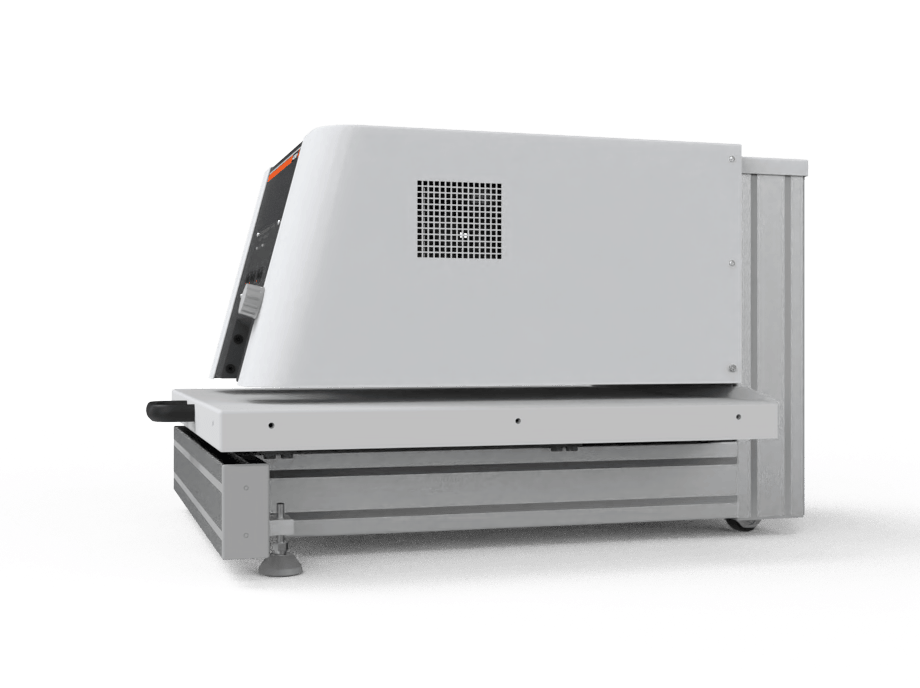

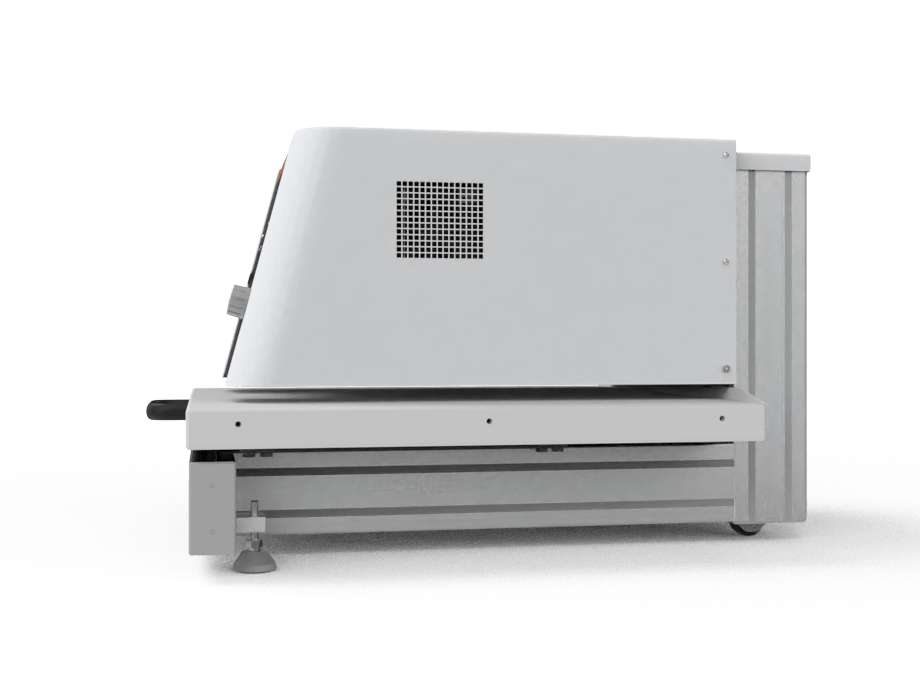

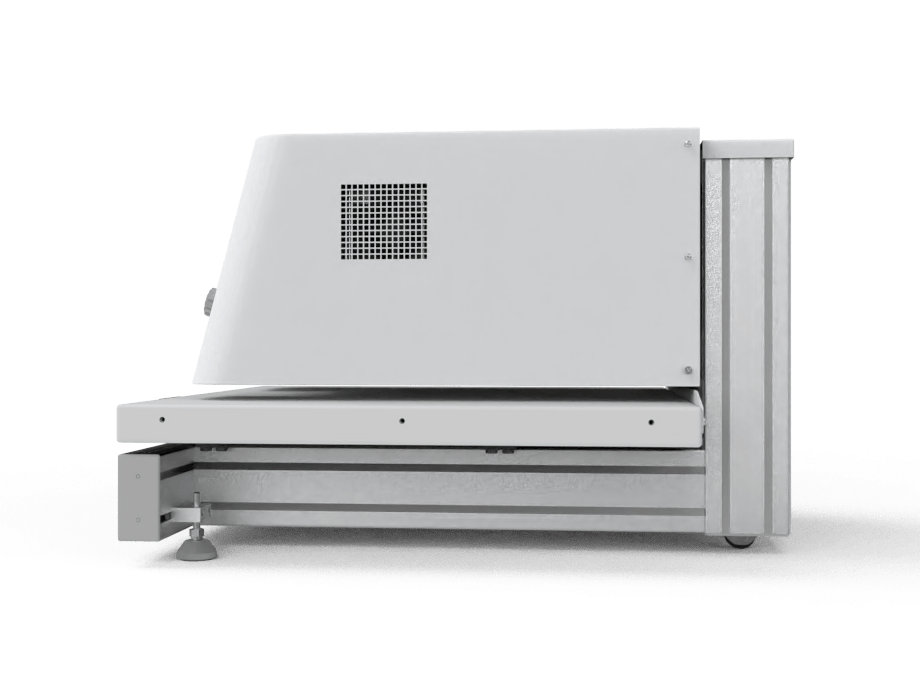

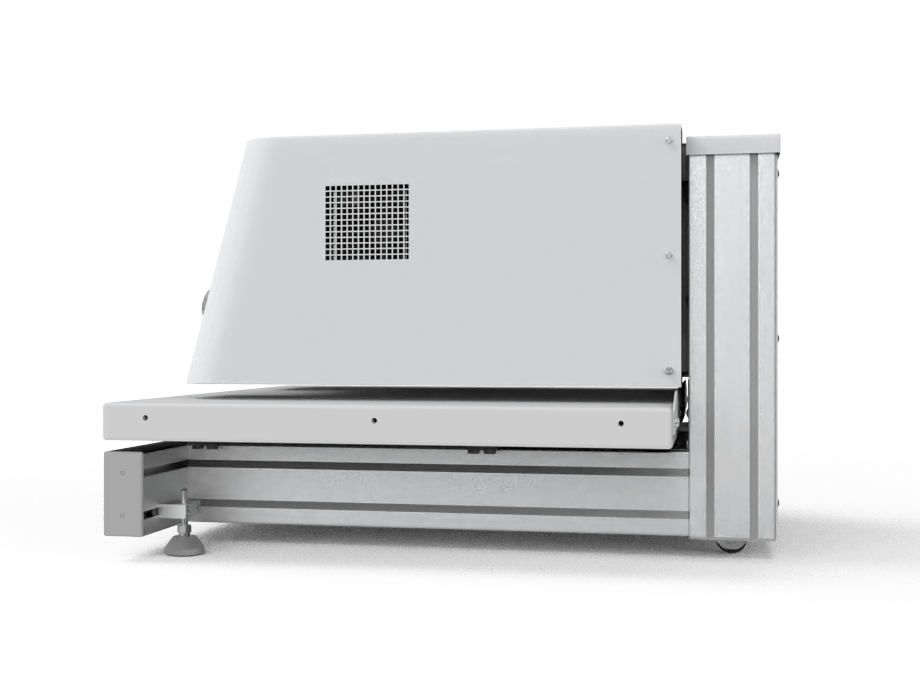

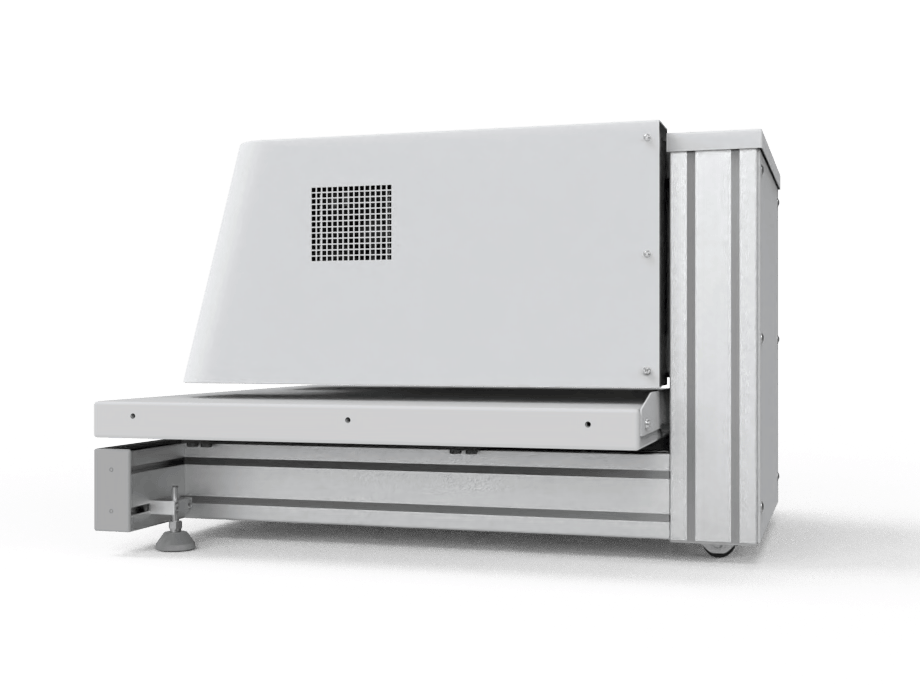

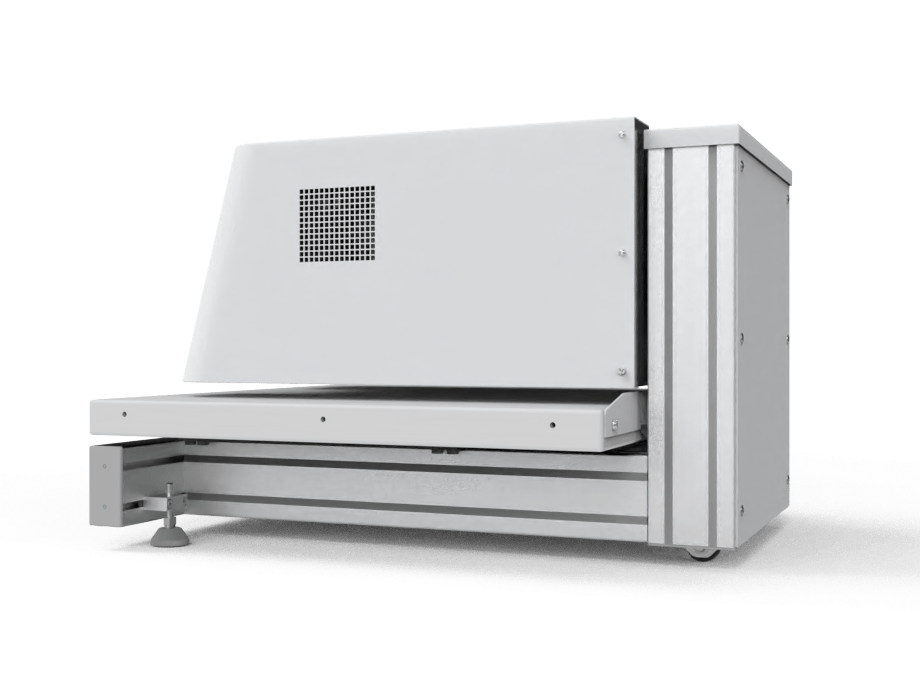

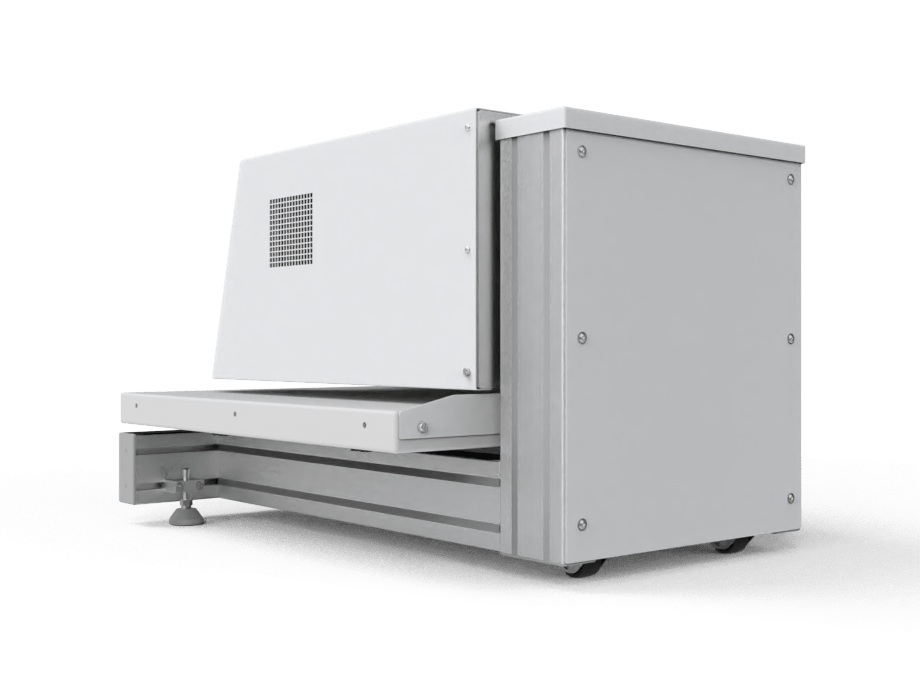

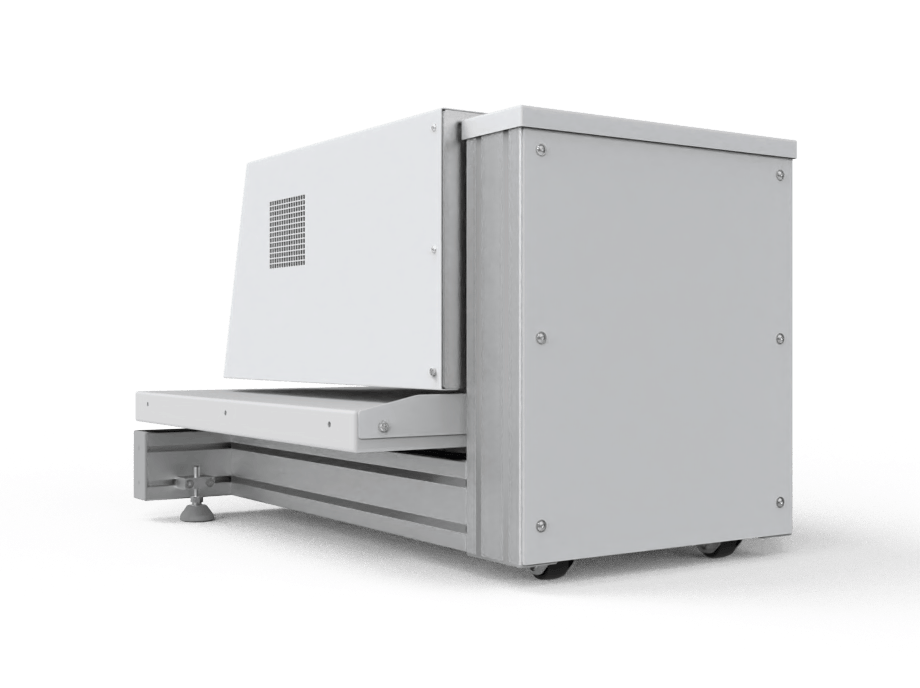

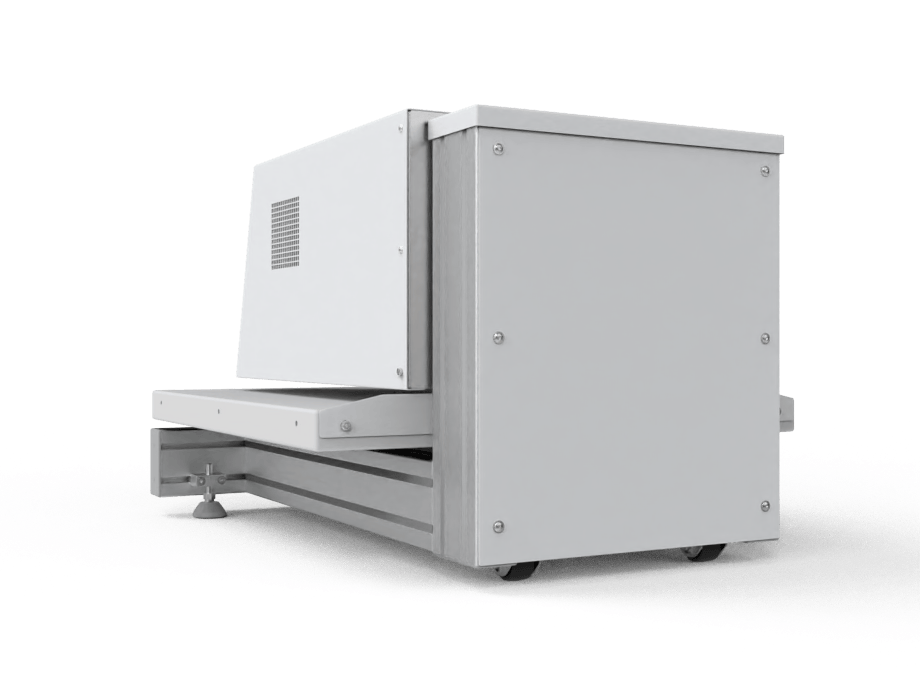

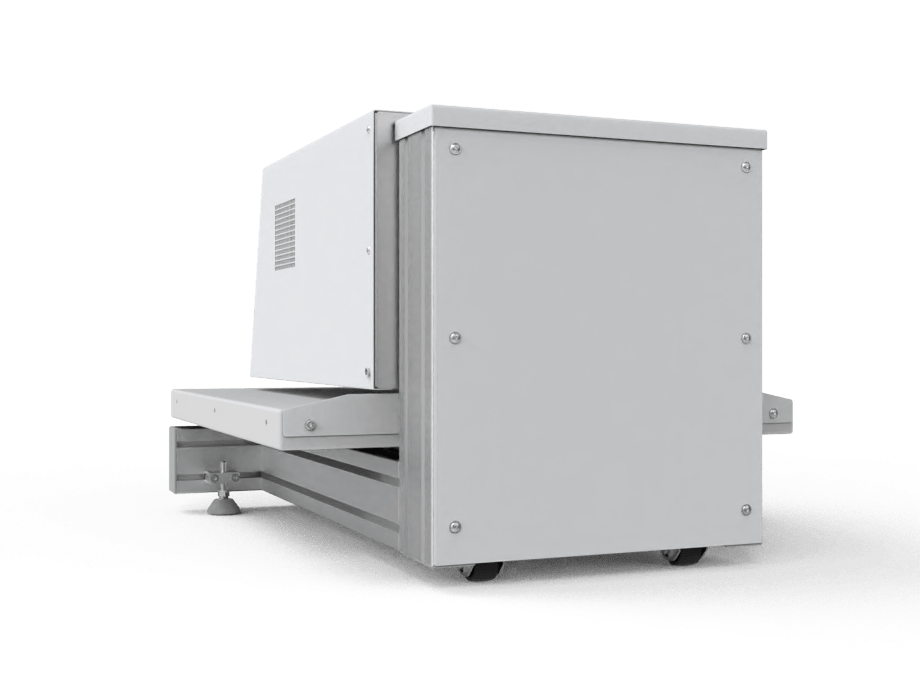

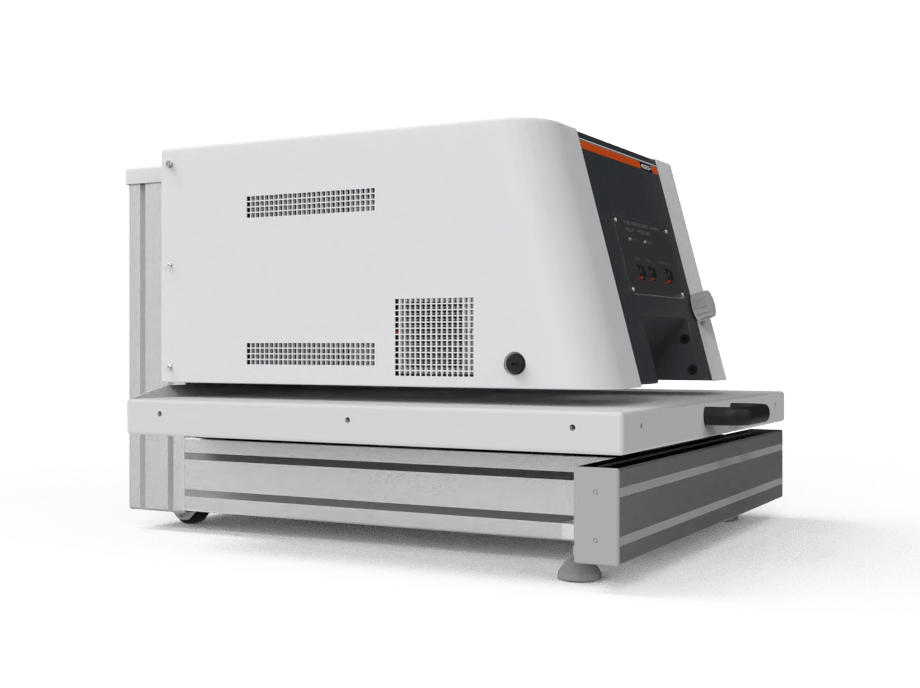

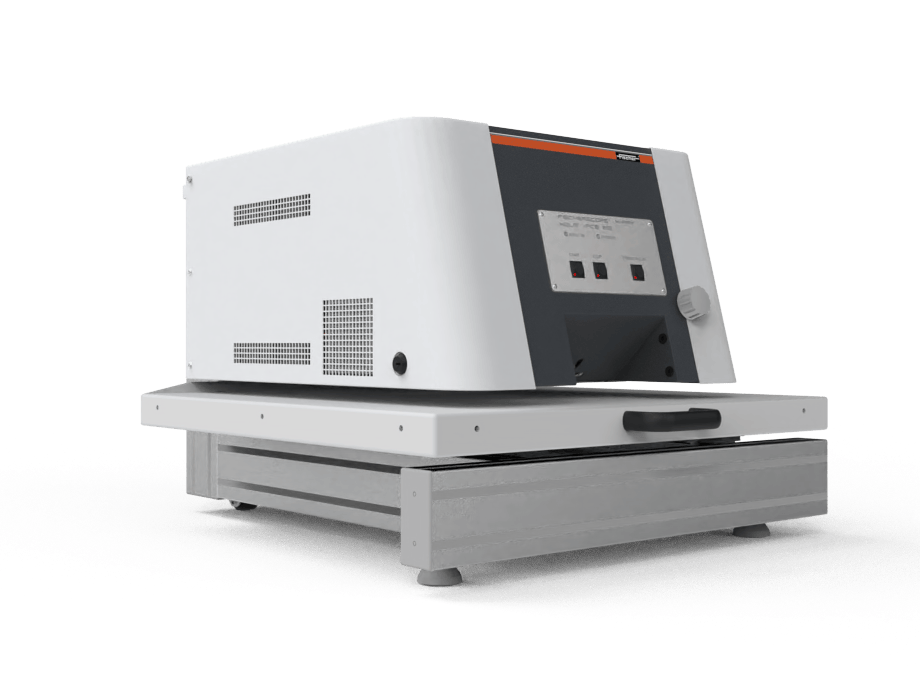

FISCHERSCOPE® X-RAY XDLM®-PCB

approx. Ø 0.2 µm

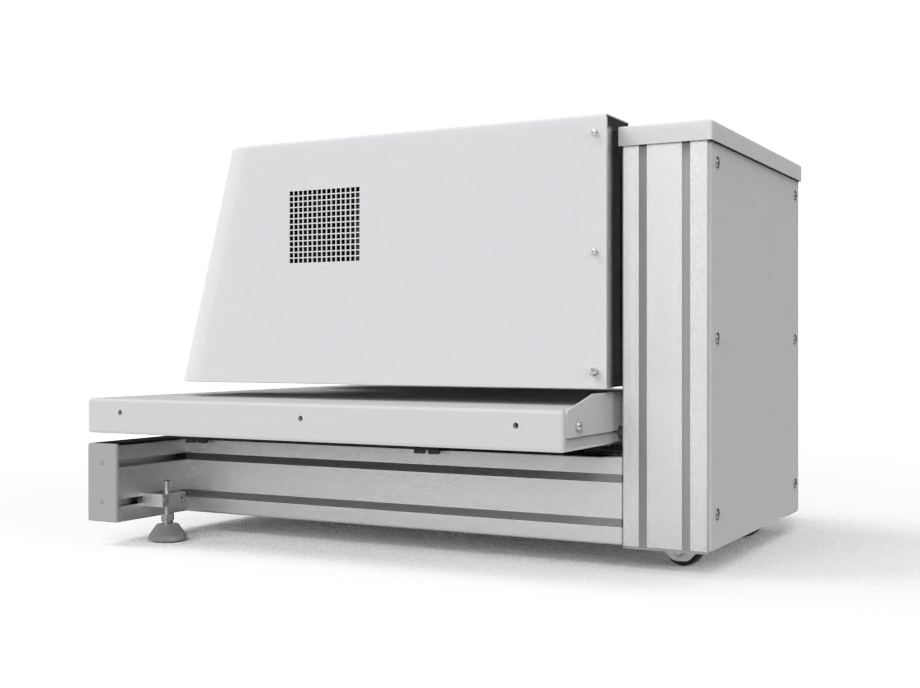

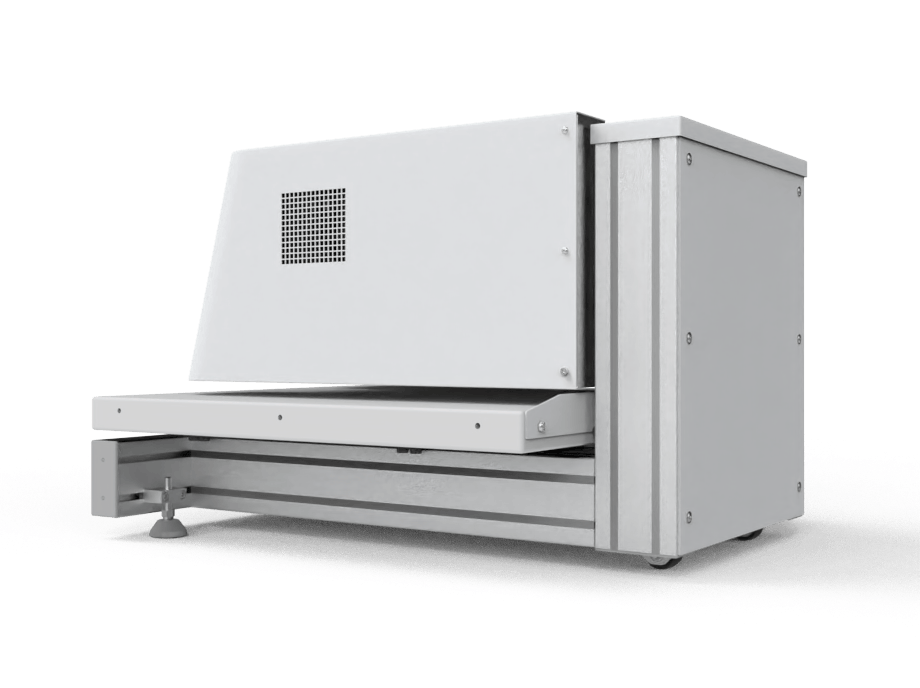

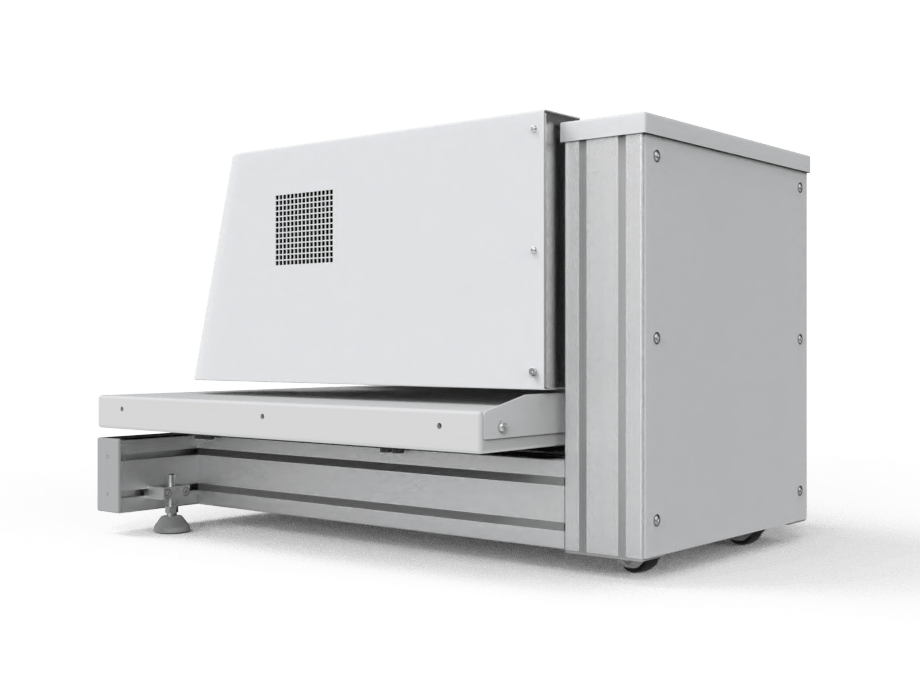

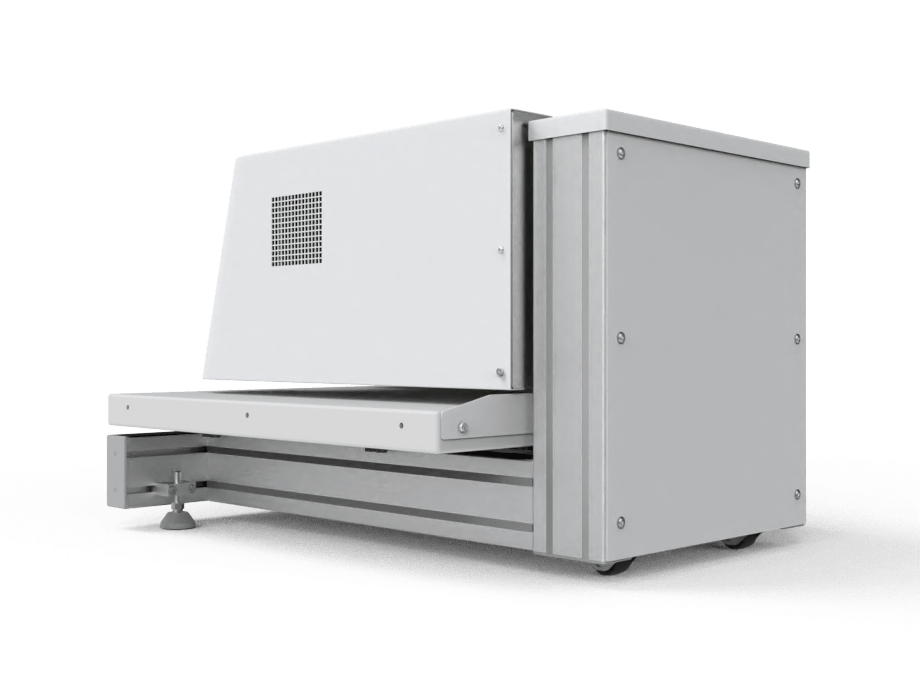

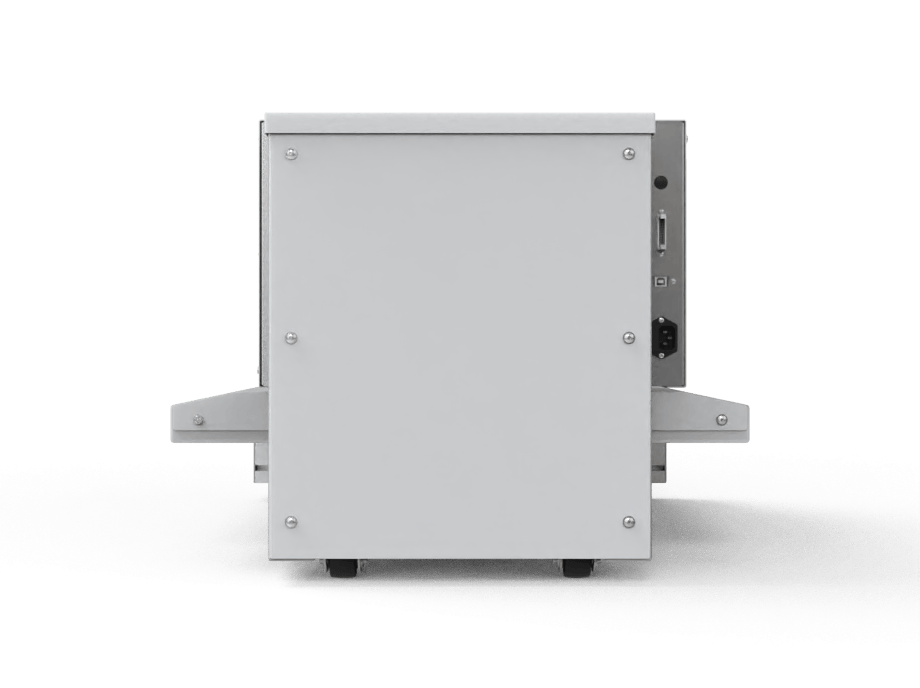

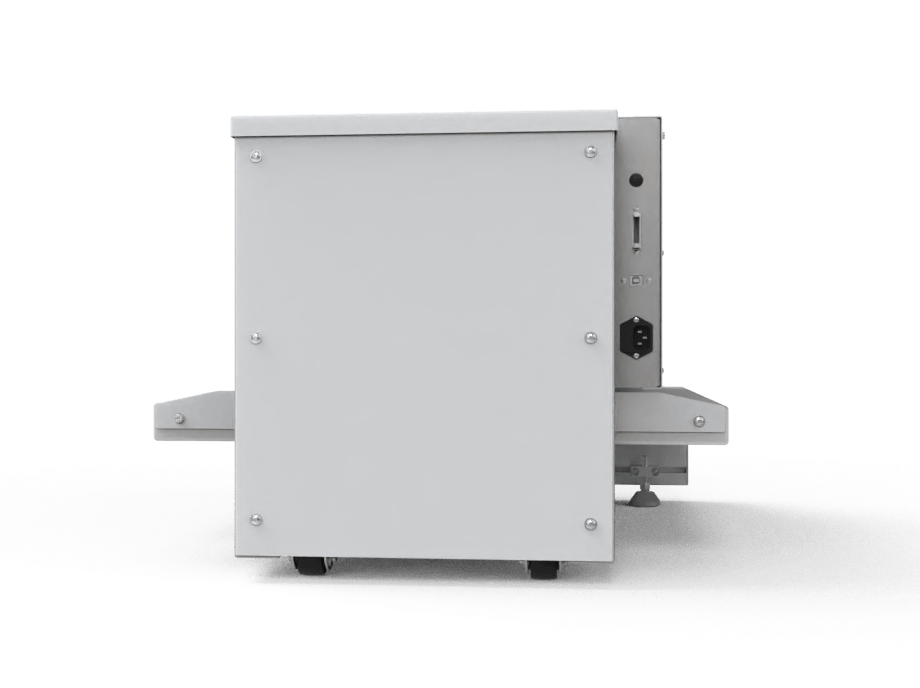

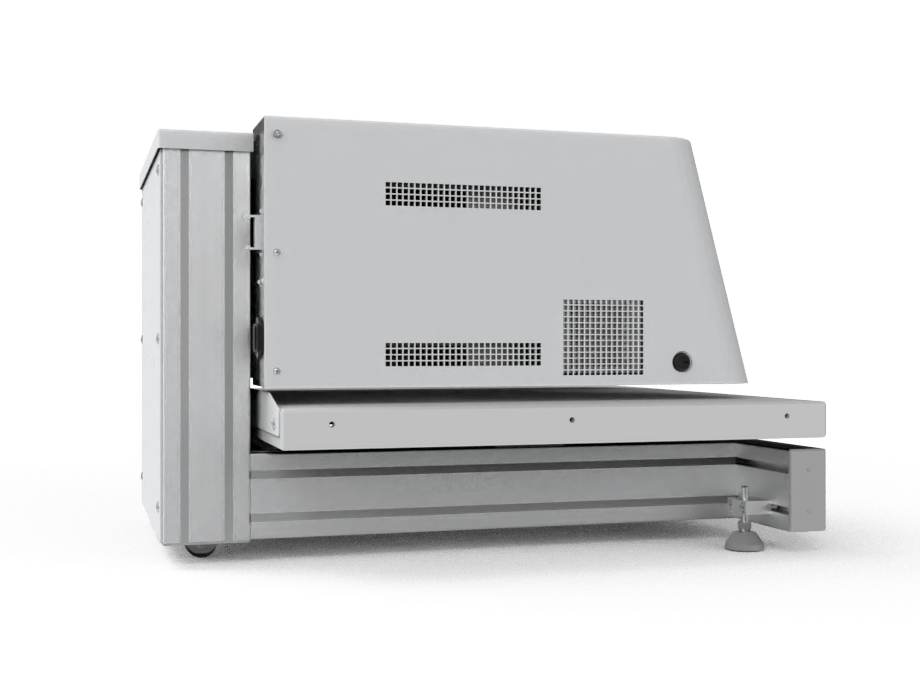

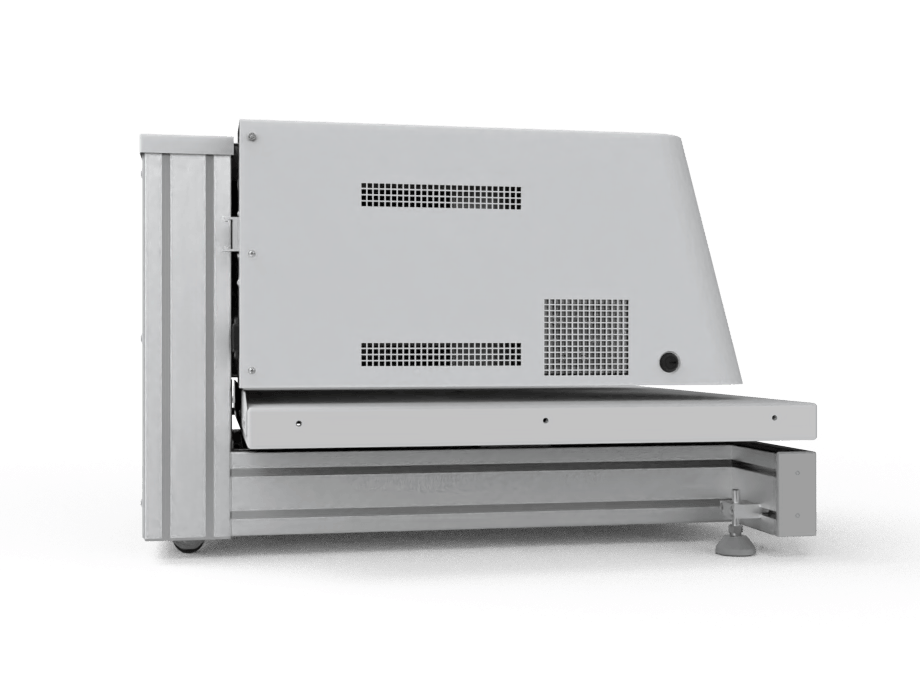

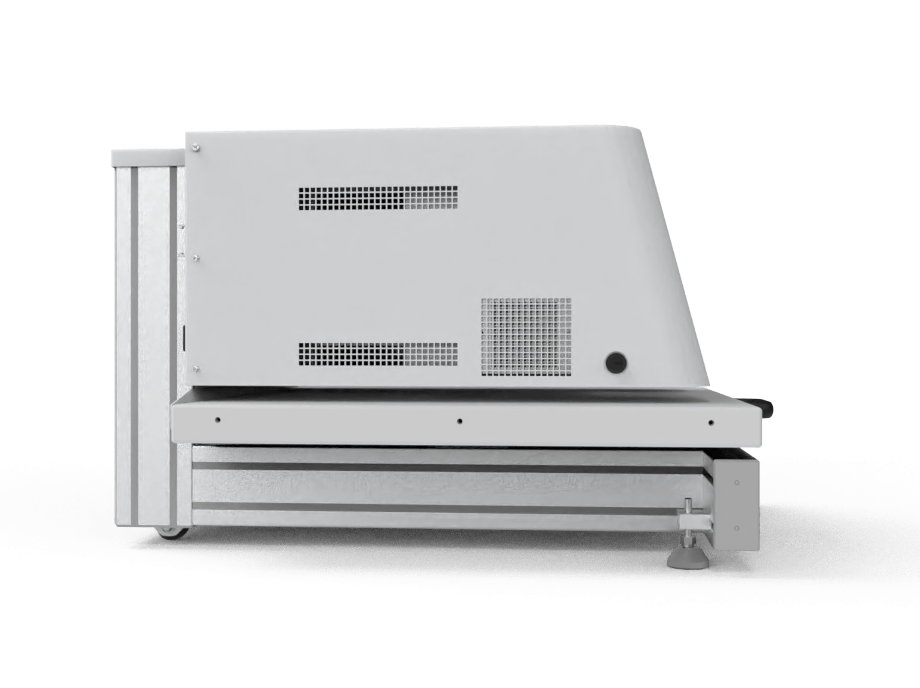

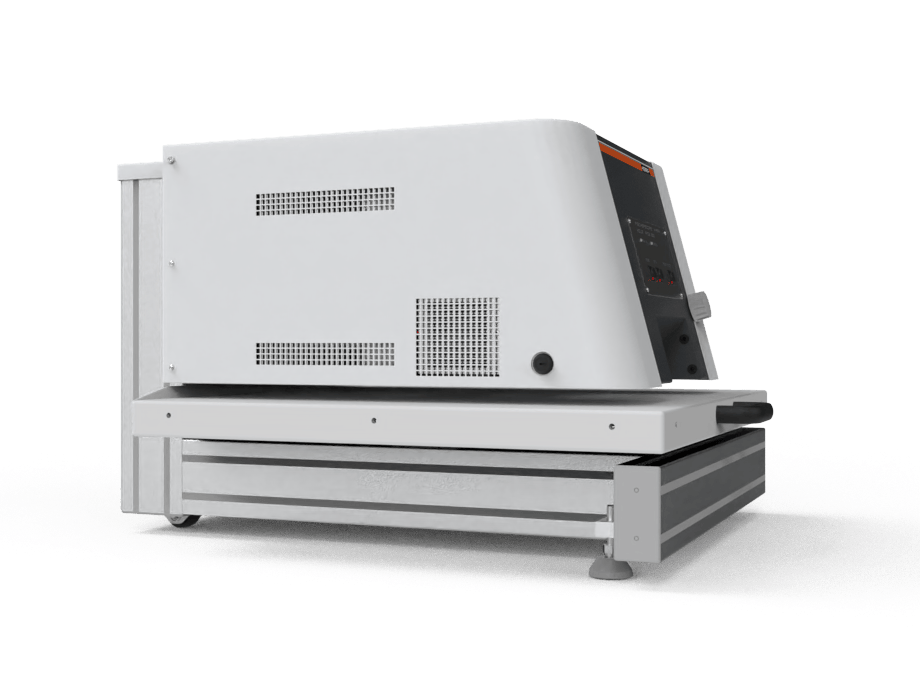

full protection device

measuring window on the market

Accurate and reliable XRF PCB inspection.

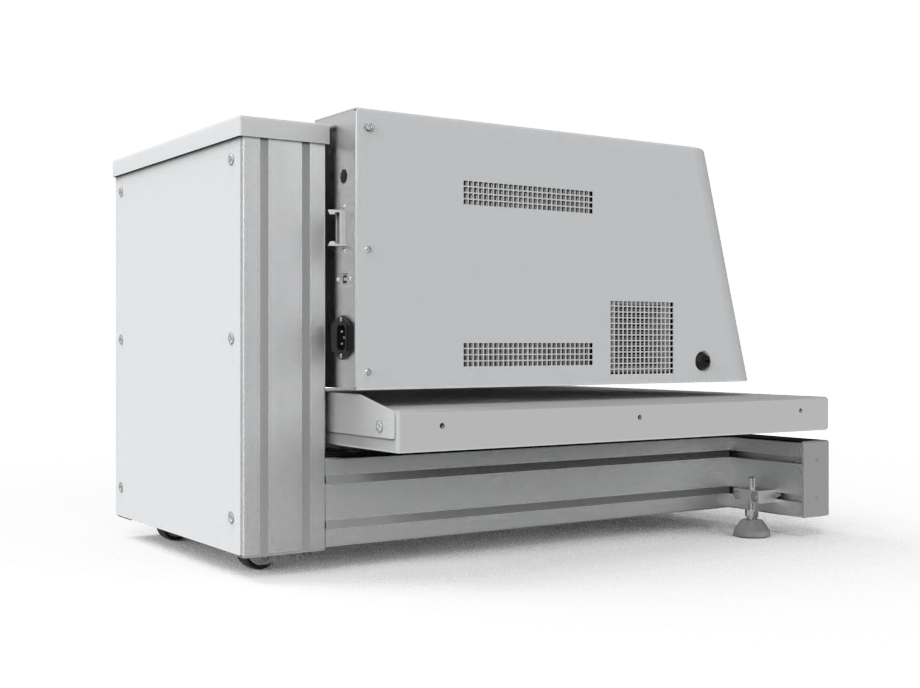

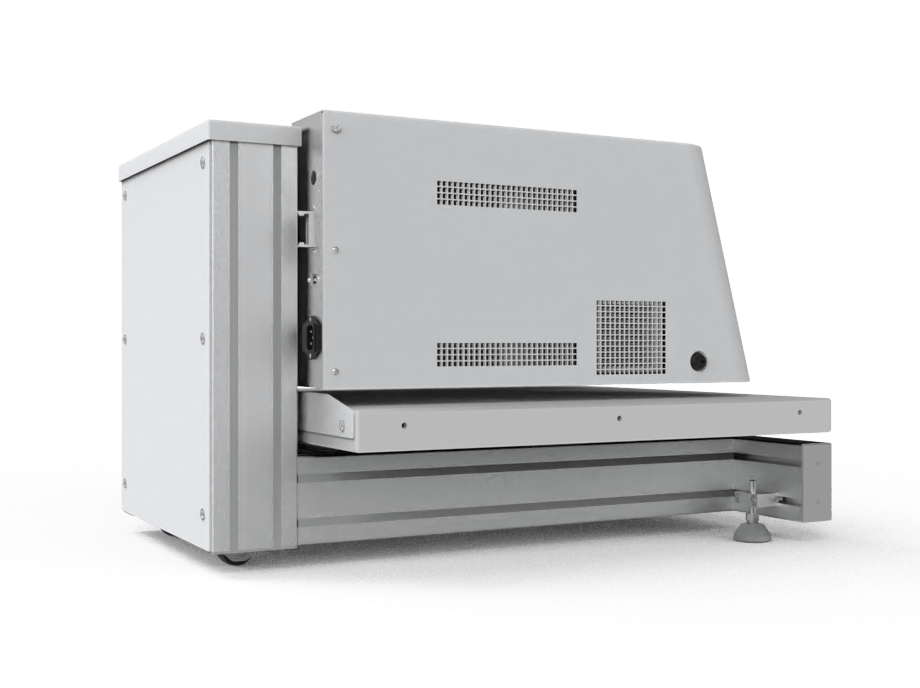

The universal entry-level instrument with a proportional counter tube detector for short measuring times is ideal for simple measurements and spot checks with a small measuring spot. Equipped with different apertures and filters, the FISCHERSCOPE® X-RAY XDLM®-PCB creates the optimal conditions for your measuring task.

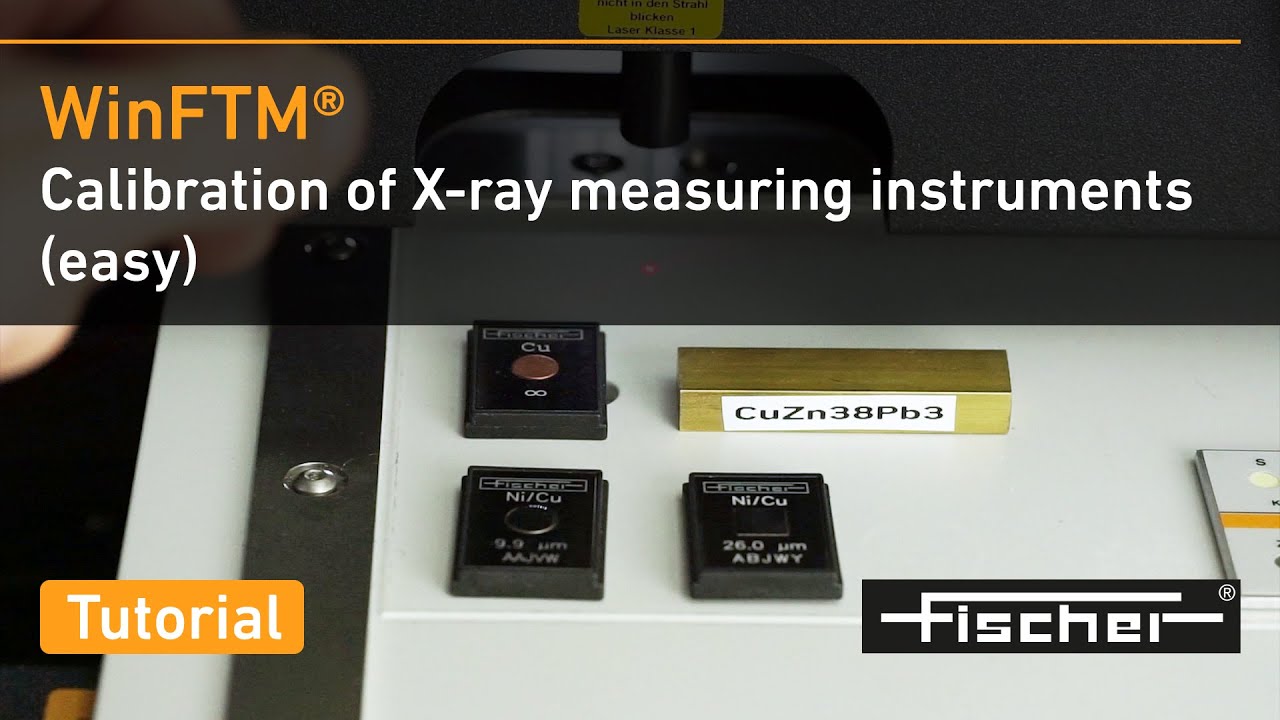

Commissioning.

Extremely fast and simple

PCB experts.

Specialized measuring solutions for printed circuit boards

Accurate and precise.

Positioning of the measuring point on small structures thanks to automatic image recognition

Balanced.

Optimal cost-benefit ratio

Tailor-made.

Different models offer the optimal solution for your application

Quick-measure-design.

The sample is placed and ready for measurement in just a few steps

Features

Microfocus tube with tungsten anode

Proportional counter tube detector for short measuring times and a small measuring spot

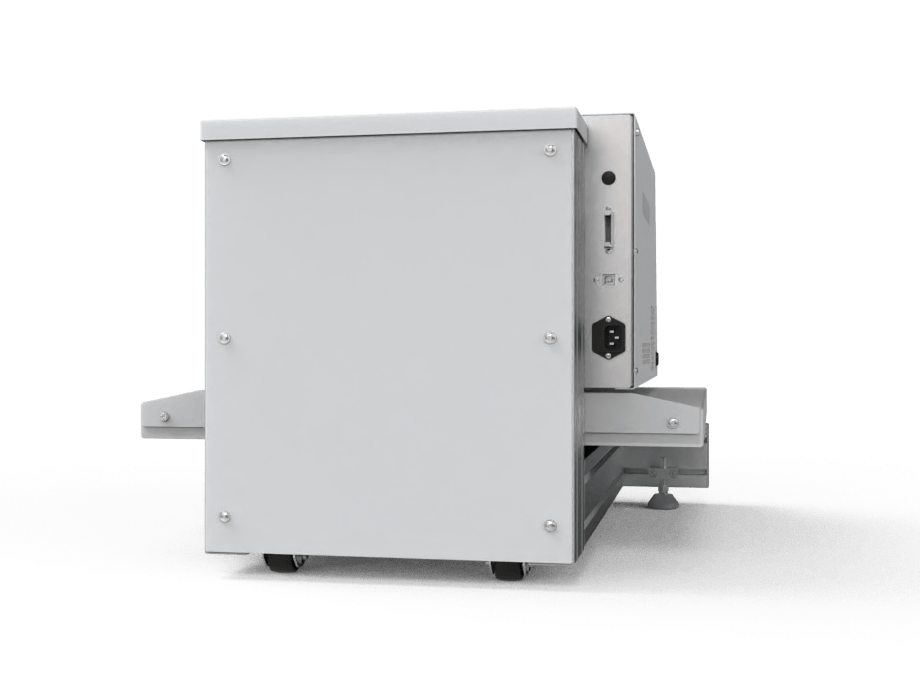

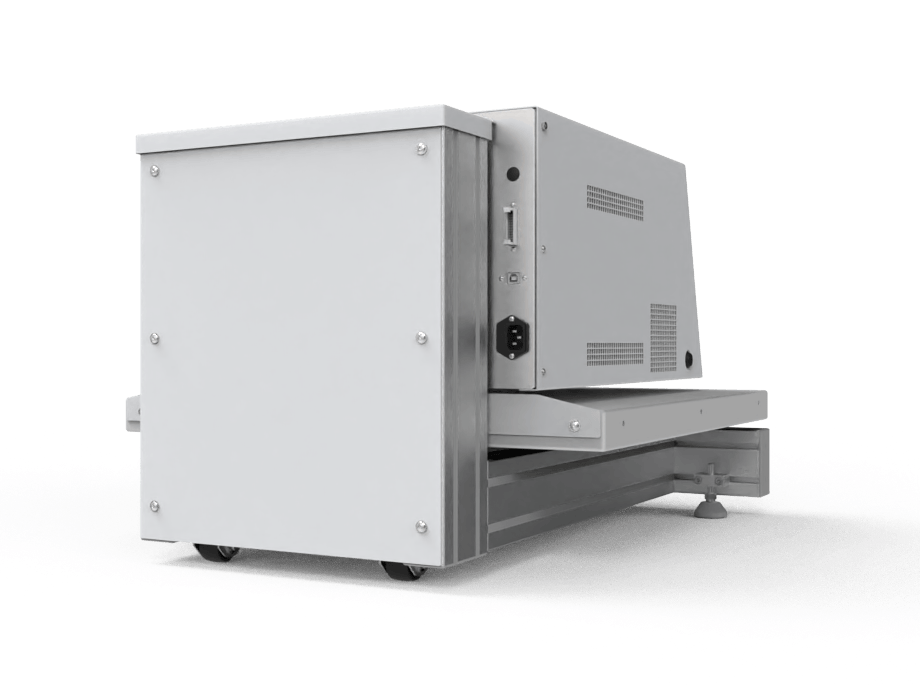

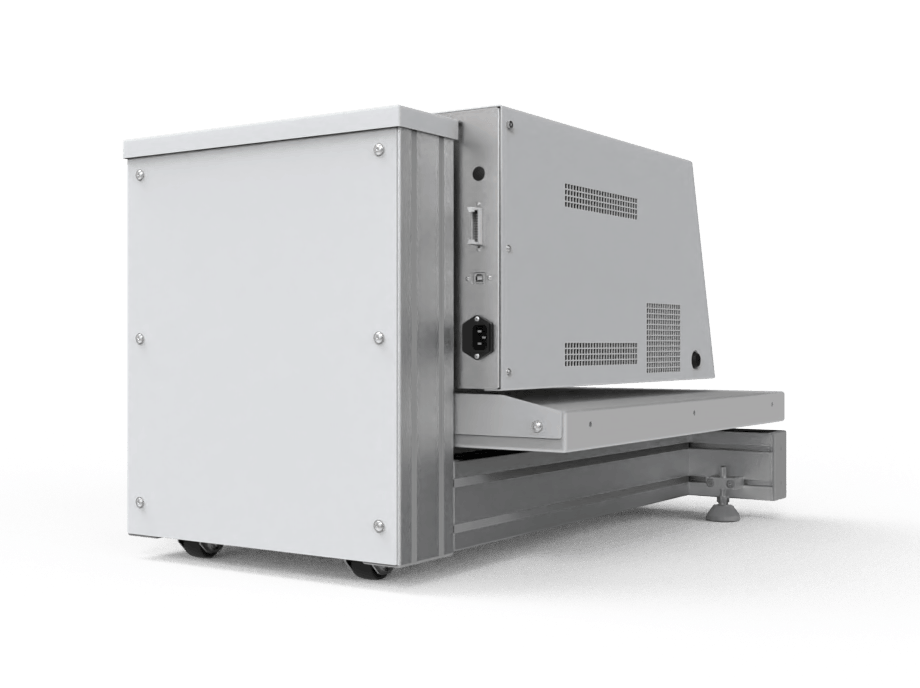

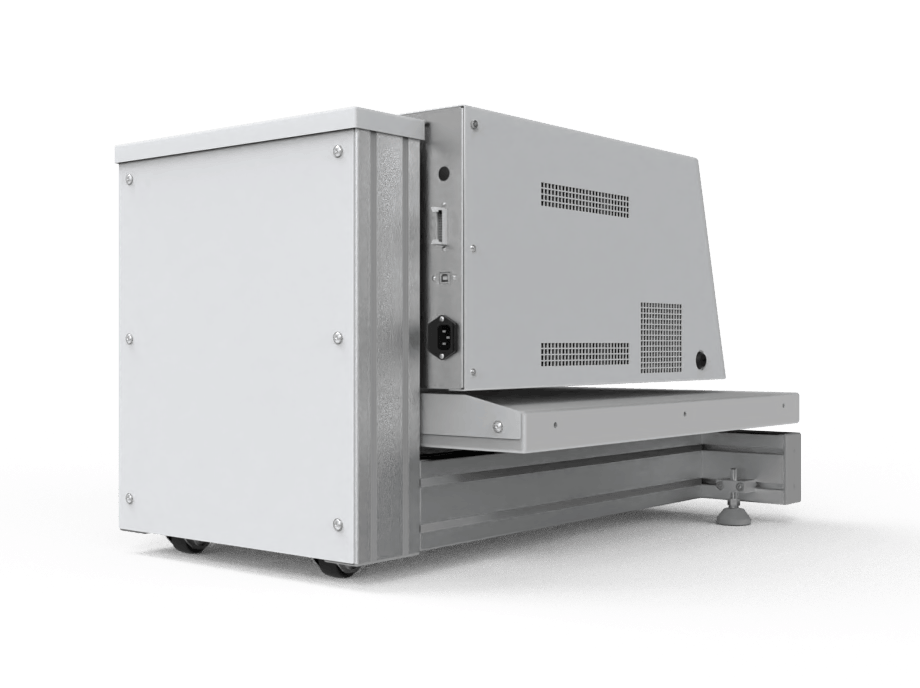

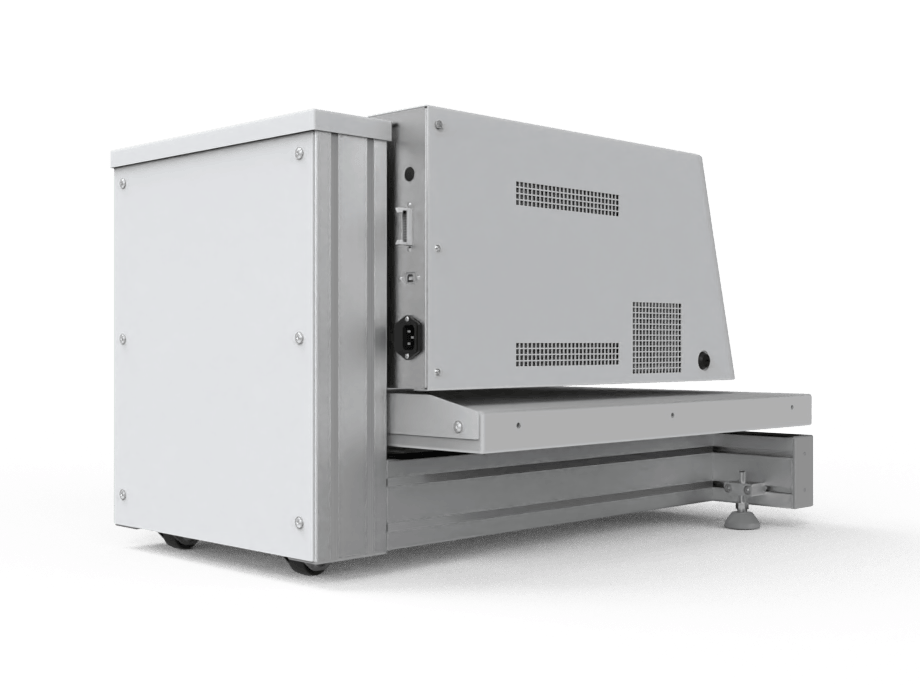

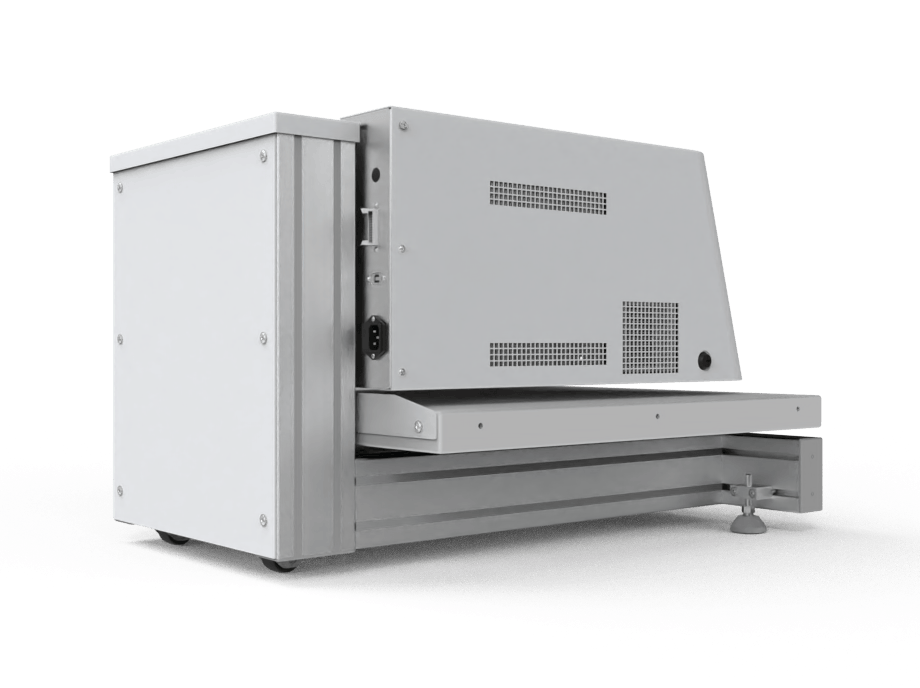

Fixed, wide measuring table for PCBs up to 610 × 610 mm, optionally with measuring table extension

Fixed aperture, optionally 4-fold changeable

Measuring spot approx.: Ø 0.2 mm

Up to 5 mm possible height of samples

Fixed filter, optionally 3-fold changeable

Measuring direction from above

Application examples

- Measuring on smallest components and structures on PCBs up to 610 x 610 mm (24 x 24 in)

- Measuring functional layers in the electronics and semiconductor industry

- XDLM®-PCB 210 and 220: Automated measuring e.g. in quality control

Do you have further applications? Then contact us!