Willkommen bei Helmut Fischer

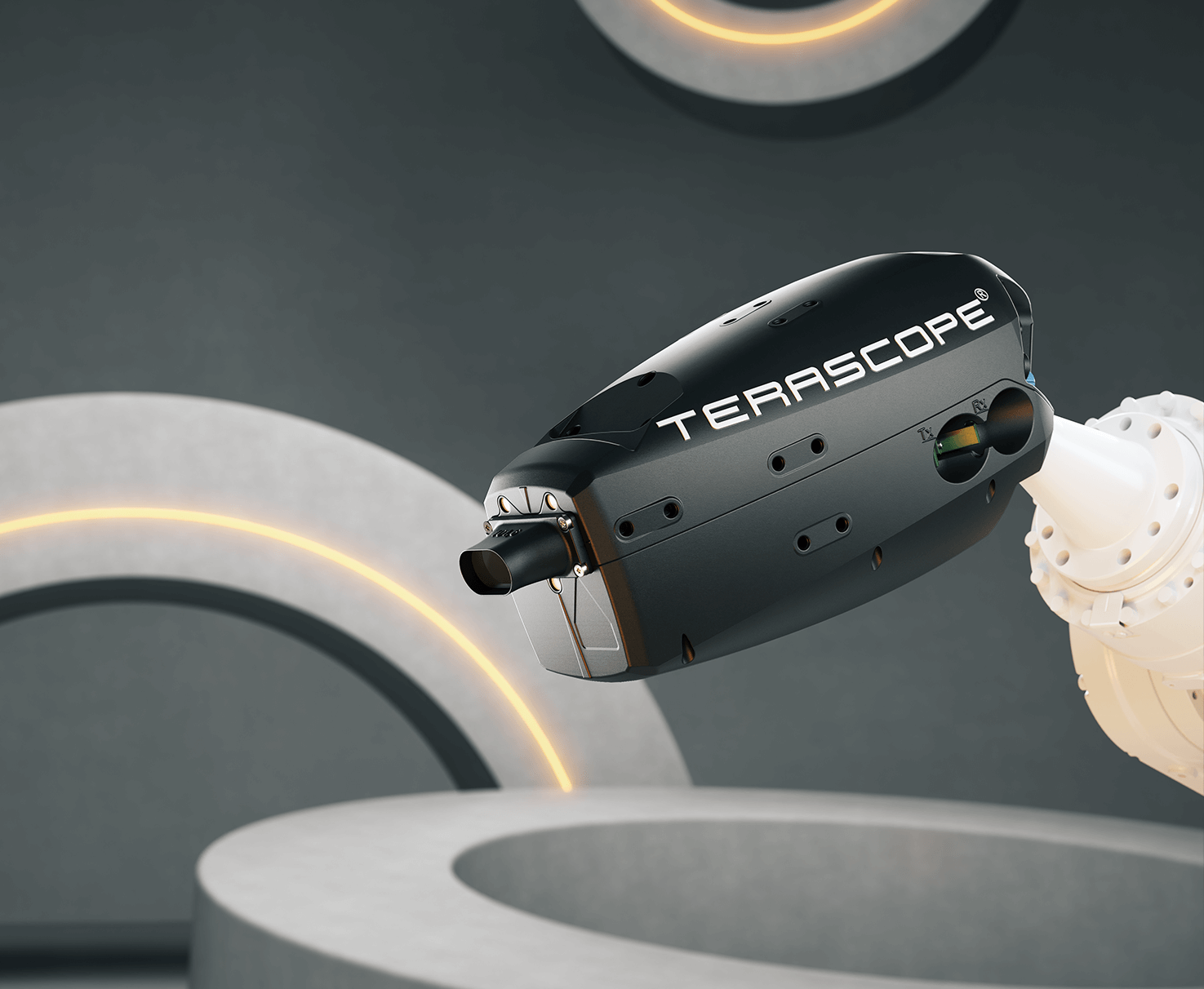

Wir sind Ihr zuverlässiger Partner im Bereich der Oberflächenprüfung. Seit 1953 entwickeln wir Lösungen für die Schichtdickenmessung, Materialanalyse, Nanoindentation und Werkstoffprüfung. Ob Sie ein Handgerät für die mobile Messung, ein zuverlässiges Tischgerät oder eine vollautomatische Messlösung für die Qualitätskontrolle in Ihrer Produktion benötigen: Als führender Hersteller von Messinstrumenten finden Sie bei uns für jede Anwendung die richtige Lösung.

Fischer 360° Betreuung

Das Rundum-Sorglos-Paket für Sie.

Einfach eine runde Sache: Wir bieten Ihnen von Anfang bis Ende alles, was Sie für eine sichere Messung benötigen. Von der Beratung über die Inbetriebnahme und Schulung bis zum After Sales.

Mehr erfahrenWarum Fischer

Das spricht für uns.

Gute Messgeräte? Ist bei weitem nicht alles, was uns auszeichnet. Entdecken Sie viele gute Gründe, die noch für uns sprechen.

Mehr erfahren